Lifting method and lifting system for six-degree-of-freedom active type wave compensation

A technology of wave compensation and hoisting method, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problem that six degrees of freedom motion compensation and swing suppression cannot be realized at the same time, and achieve the effect of suppressing load swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

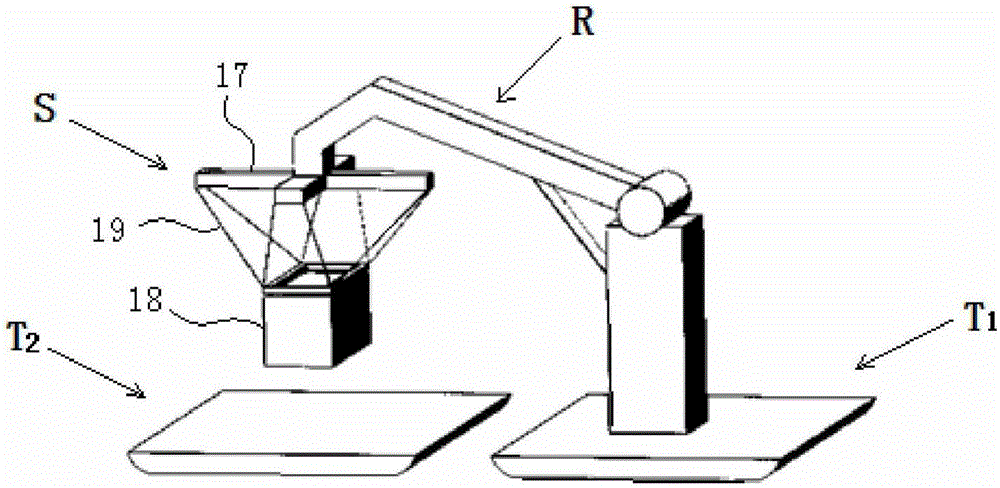

[0025] supply ship T 1 and the supply ship T 2 The situation of the two ships relying on the supply operation is as follows: figure 1 As shown, the six-degree-of-freedom active wave compensation hoisting system S of the present invention is installed on the supply ship T 1 on the boom R of the crane.

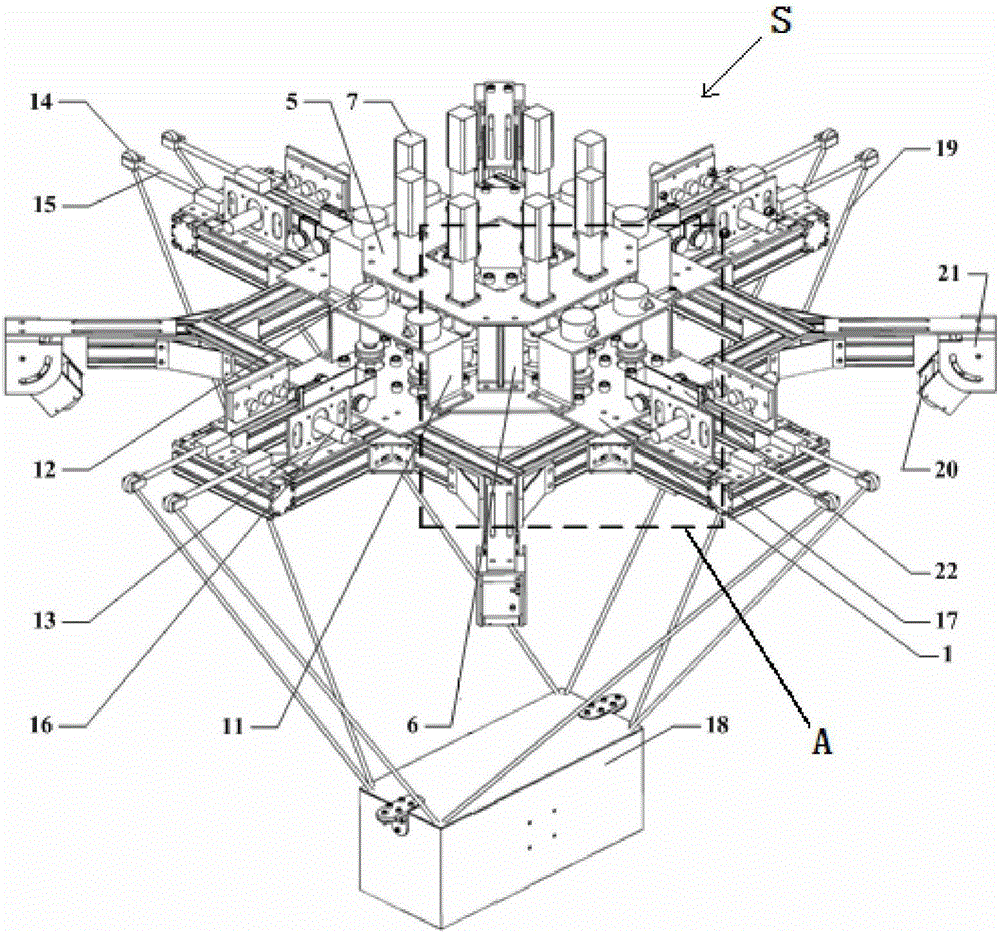

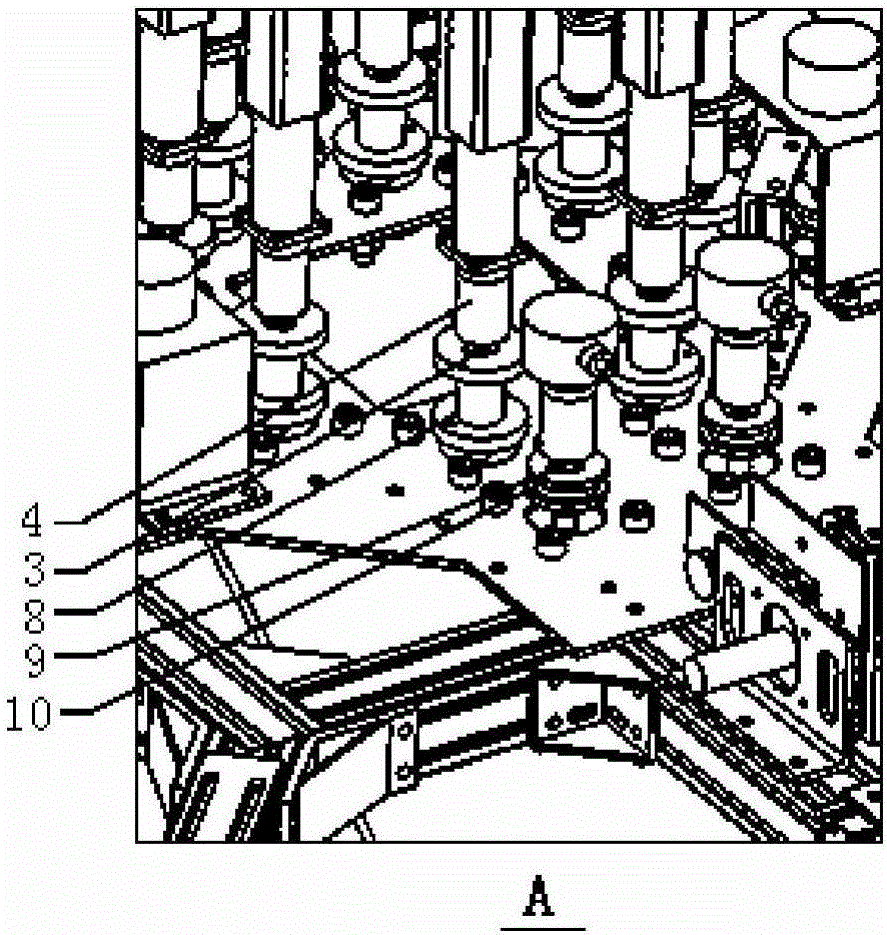

[0026] Six degrees of freedom active wave compensation hoisting system S such as figure 2-shown in 4, comprise the pedestal 17 that is located on the crane arm of supply ship, described pedestal 17 is provided with eight cover servo systems and a cover detection system; Each cover servo system all comprises control part, by control part The controlled servo motor deceleration device 7, the wire rope traction sling system driven by the servo motor deceleration device 7; the detection system includes two cameras 20 and its image data acquisition card. The control part includes a PC, an analog output data acquisition card, a motor driver, an absolute encoder 12, an RS485 input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com