An electronically controlled hoisting wire rope auxiliary tensioning system and method

A technology of tensioning system and steel wire rope, which is applied in hoisting device, spring mechanism, etc., can solve the problems of wire rope disorder and damaged wire rope, etc., and achieve the effect of flexible use, reliable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

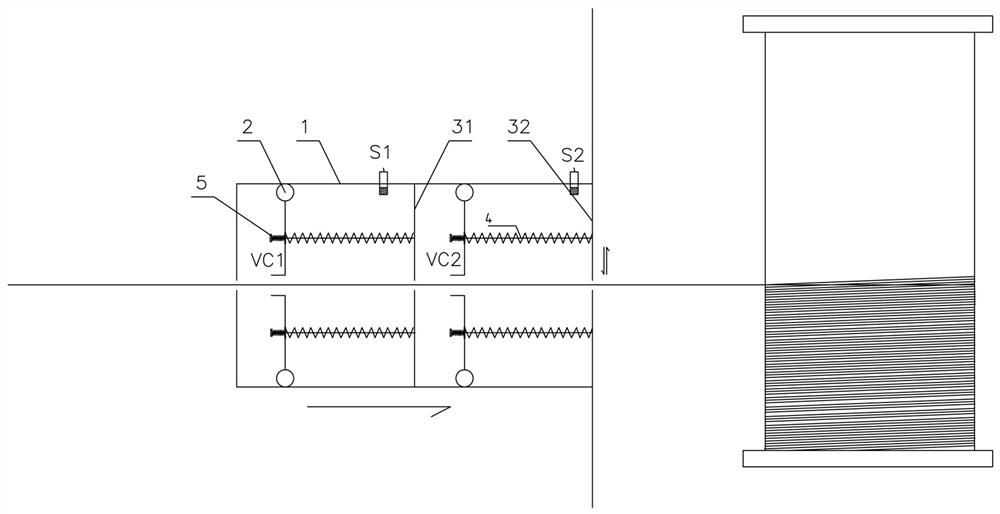

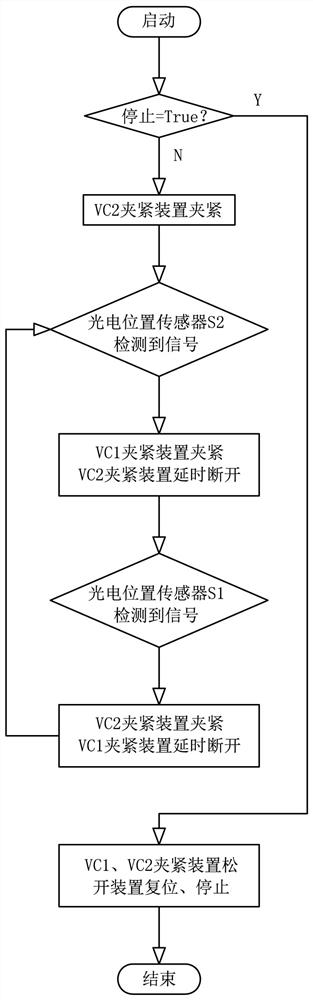

[0022] Such as figure 1 As shown, an electronically controlled hoisting wire rope auxiliary tensioning system, the electrically controlled hoisting wire rope auxiliary tensioning system includes a set of auxiliary tensioning device; the auxiliary tensioning device includes a controller, a support frame 1, The electric control clamping device VC1 and the electric control clamping device VC2 for clamping the steel wire rope when retracting and unwinding the rope correspond to each electric control clamping device and are used to detect the position detection sensors S1 and S2 of the electric control clamping device's moving position The supporting frame 1 is provided with a sliding bar with ball bearings 2, and the electronically controlled clamping device VC1 and the electronically controlled clamping device VC2 are arranged on the sliding bar through the ball bearings 2. The electronically controlled clamping device VC1 and the electronically controlled clamping device VC2 are...

Embodiment 2

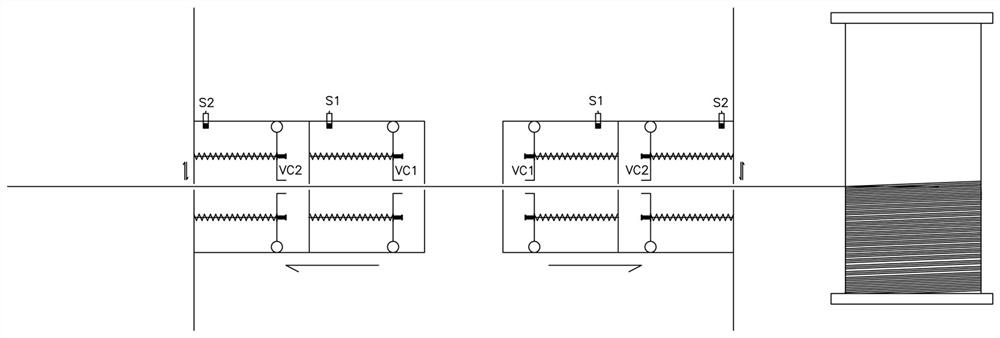

[0031] The difference between this embodiment and Embodiment 1 is that in the case where the wire rope is slack in both directions of retracting and unwinding the rope, in order to prevent the slack of the wire rope well, the electronically controlled hoisting wire rope assists tensioning The system includes two sets of auxiliary tensioning devices symmetrically arranged in the direction of wire rope retraction and release. It should be noted that, in other embodiments, the positions of the electronically controlled clamping devices in the two sets of auxiliary tensioning devices can be slightly changed to meet the control program flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com