A fiber-reinforced silicate plate for outdoor planks, its preparation method and application

A fiber-reinforced, silicate technology, applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve the problem that the appearance and natural texture of silicate light boards are not as good as wooden boards, poor impact resistance, and increase the system Cost and other issues, to achieve the effect of ensuring freeze-thaw resistance, high flexural strength, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

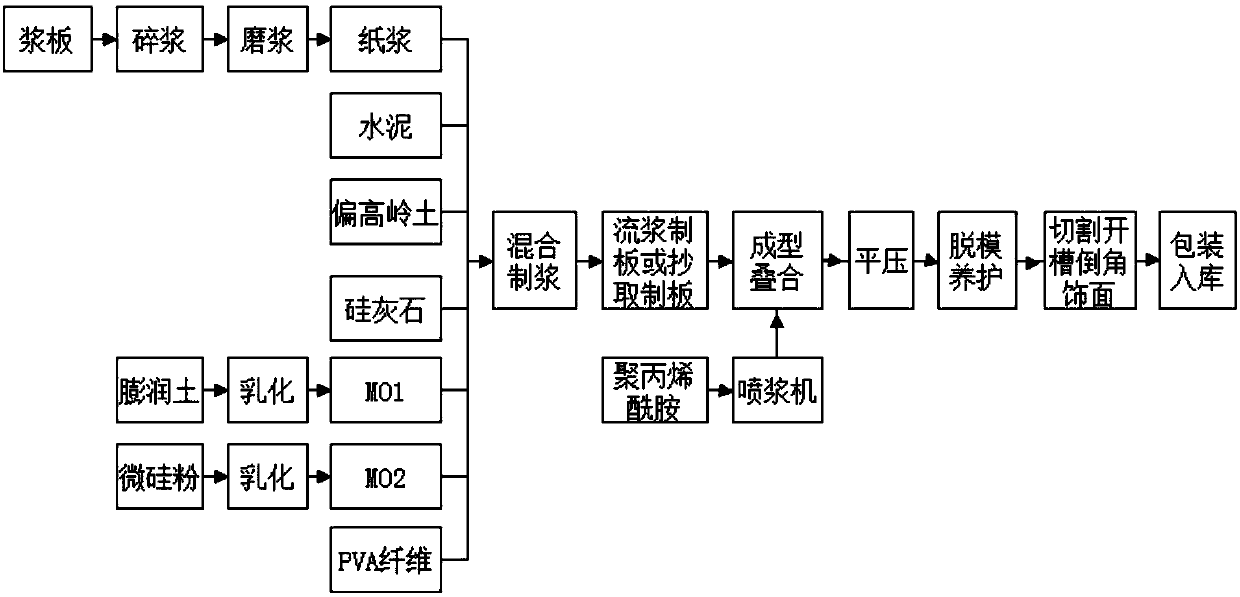

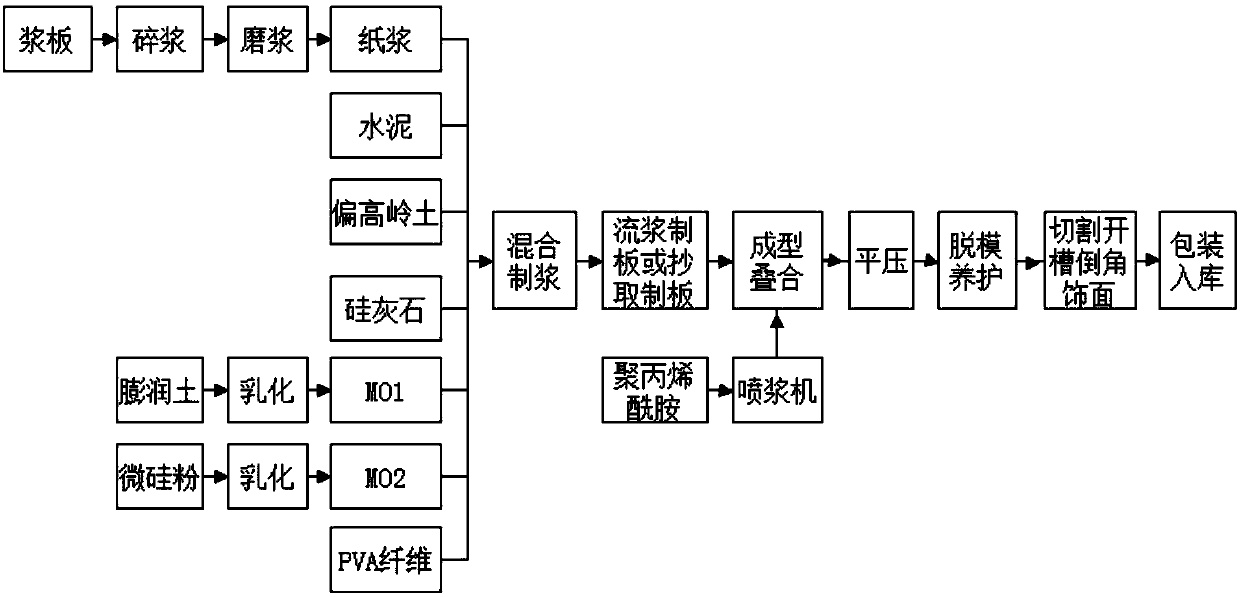

[0069] A fiber-reinforced silicate board for outdoor plank road, and its production process is as follows figure 1 shown, including the following steps:

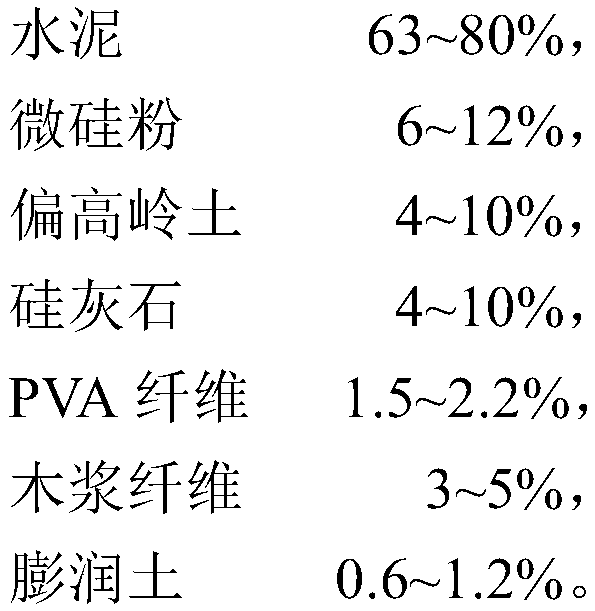

[0070] 1) After pulping and refining the wood pulp board, it is prepared into pulp for later use; the bentonite is emulsified in an emulsifying machine for 1 hour with a concentration of 10%, and the microsilica powder is emulsified in an emulsifying machine for 1 h with a concentration of 30% for standby;

[0071] 2) After each material is mixed in proportion, add water and stir and control the concentration to 10%, form a thin material layer with a thickness of 1.0mm through flow slurry, and then stack each thin material layer through a forming cylinder to form a whole with a thickness of 20mm. Slab; during the multi-layer lamination process of the forming cylinder, the polyacrylamide solution is sprayed uniformly and continuously between each layer, and the spray amount is 200ppm of the dry material weight of the material...

Embodiment 2

[0078] A fiber-reinforced silicate board for outdoor plank road, the preparation steps are the same as those in Example 1, and the difference is:

[0079] In step 2), the concentration after adding water and stirring is 30%, and the plate is made by copying.

[0080] The plate making machine used is a copying plate making machine.

Embodiment 3

[0082] A fiber-reinforced silicate board for outdoor plank road, the preparation steps are the same as those in Example 1, and the difference is:

[0083] In step 2), the concentration after adding water and stirring is 20%, the thickness of the thin material layer is 1.2 mm, the thickness of the slab is 30 mm, and the injection amount of the polyacrylamide solution is 400 ppm of the dry material weight of the material layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com