System and method for improving crude oil dehydration efficiency of multi-purpose station

A technology of crude oil dehydration and combined station, which is applied in the fields of hydrocarbon oil dehydration/demulsification, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of excessive water content in purified oil and the entry of purified oil into three-phase separators, and achieve digital management. , Improve crude oil dehydration efficiency, reduce labor intensity and the effect of combined station operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

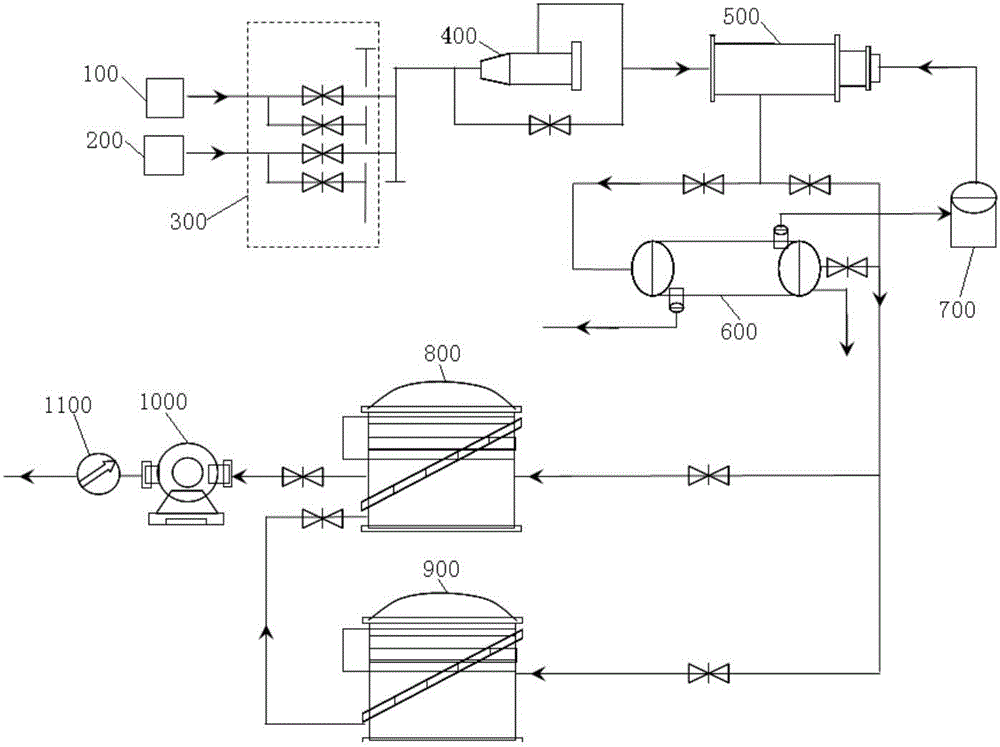

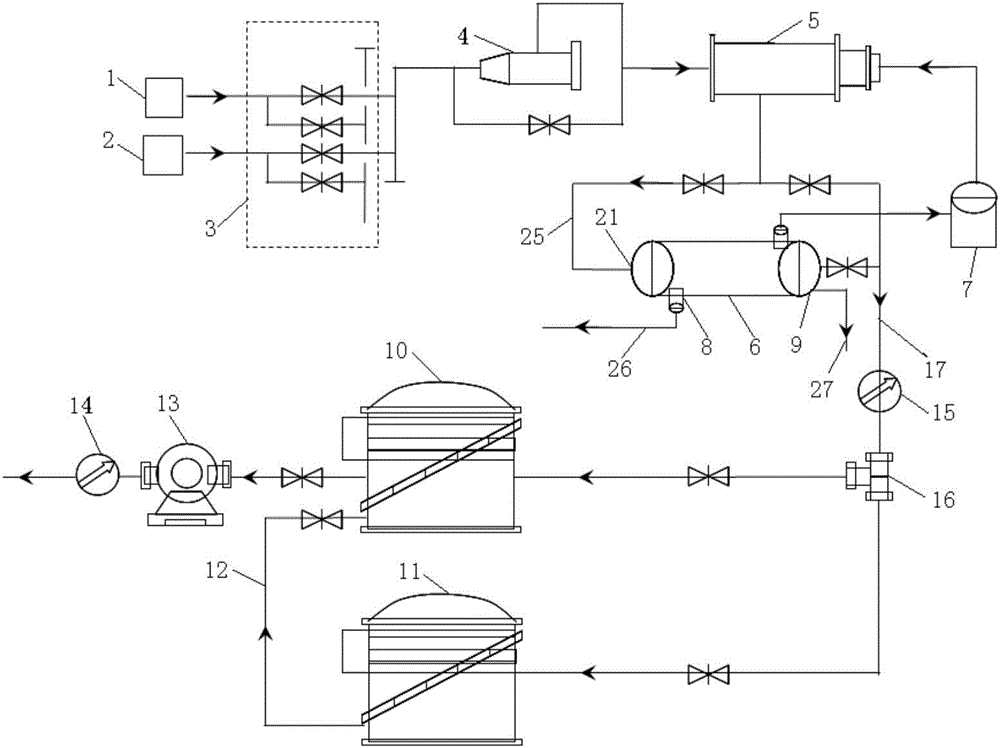

[0027] Such as figure 2 As shown, a system for improving the dehydration efficiency of crude oil in the combined station provided by the embodiment of the present invention includes the oil supply points connected in sequence along the flow direction of crude oil, the main engine 3, the ball collecting device 4, the heating furnace 5, and the three-phase separator 6. The three-phase separator 6 is connected to the purified oil outlet pipeline 17, and the purified oil outlet pipeline 17 is sequentially provided with a water content monitor 15 and a solenoid valve 16 along the crude oil flow direction, and the water content monitor 15 and the solenoid valve 16 Connect a controller by wire; Described electromagnetic valve 16 is respectively connected a purified oil tank 10 and a settling tank 11 by wire connection, and described settling tank 11 is connected described purified oil tank 10 by overflow line 12, described purified oil The tank 10 is connected with an external deliv...

Embodiment 2

[0032] On the basis of Example 1, such as Figures 2 to 4 As shown, the solenoid valve 16 is a three-position three-way solenoid valve 4, and it is more convenient to use a three-position three-way solenoid valve circuit control.

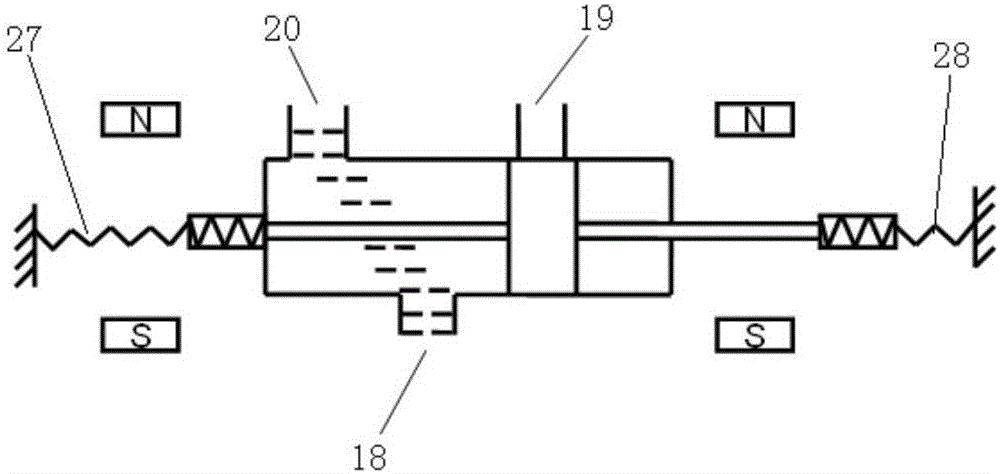

[0033] Such as Figures 3 to 5As shown, the solenoid valve 16 has an inflow port 18, a first outflow port 19, and a second outflow port 20, the inflow port 18 is connected to the water content monitor 15 through a purified oil outlet line 17, and the first outflow port 19 is connected to the water content monitor 15 through a purified oil outlet line 17. The pipeline is connected to the purified oil tank 10, and the second outflow port 20 is connected to the settling tank 11 through the pipeline.

[0034] Such as image 3 As shown, the left coil 27 of the electromagnetic valve 16 is energized, and the second outflow port 20 is opened; as Figure 5 As shown, the right coil 28 of the solenoid valve 16 is energized, and the first outlet 19 is opened...

Embodiment 3

[0036] On the basis of Example 1, such as figure 2 As shown, the three-phase separator 6 is provided with a water-containing crude oil inlet 21, a sludge outlet 8, a gas-liquid outlet 23, a produced water outlet 9, and a water-containing crude oil outlet 24; the water-containing crude oil inlet 21 is connected to the water-containing crude oil pipeline 25 One end, the other end of the water-containing crude oil pipeline 25 communicates with the heating furnace 5 . The water-containing crude oil outlet 24 is connected to one end of the purified oil outlet pipeline 17 , and the other end of the purified oil outlet pipeline 17 is connected to the water content monitor 15 . The sludge outlet 8 is connected to a sewage discharge pipe 26, and the sewage discharge pipe discharges the waste separated by the three-phase separator 6. The gas-liquid outlet 23 is connected to the gas-liquid separator 7 through a pipeline, and the gas-liquid separator 7 is connected to the heating furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com