Surrounding edge machining device

A processing device and fringing technology, which is applied to the control device for sewing machines, sewing machines for sewing quilts, textiles and paper making, etc. It can solve the problems of troublesome height and inclination adjustment, long operating time for workers, and heavy sewing machines. Achieve good cutting effect, improve production efficiency and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

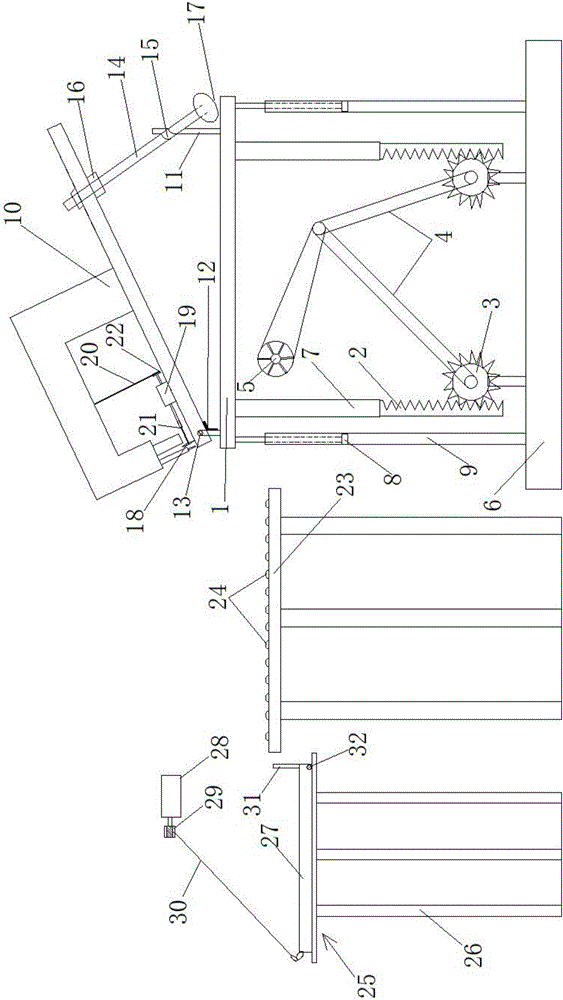

[0026] figure 1 It is an overall structural diagram of a peripheral edge processing device according to an embodiment of the present invention.

[0027] Such as figure 1 As shown, this embodiment describes a peripheral processing device, including a fabric placement platform and a sewing device arranged beside the fabric placement platform, the fabric placement platform includes a placement table 23, a turning table 25 and a table turning mechanism, Several universal balls 24 are evenly fixed on the placing table 23, and the several universal balls 24 constitute a moving plane that can roll on it, and the fixed end surface of the turning table 25 is close to the bottom of the placing table 23. Set on the side, the end face opposite to the fixed end face on the flip table 25 is a movable end face, and the movable end face is connected with a table turning mechanism, and the table turning mechanism is used to drive the turning table 25 to rotate.

[0028] It can be understood ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com