Earthing removing method for phosphate mine cave

A mine and cave technology, applied in the field of excavators, can solve the problems of reducing the service life of gear rods and tooth tips, working loads, large impact loads, and increased costs, and achieve the effects of convenient excavation and transfer, increased strength, and accelerated loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

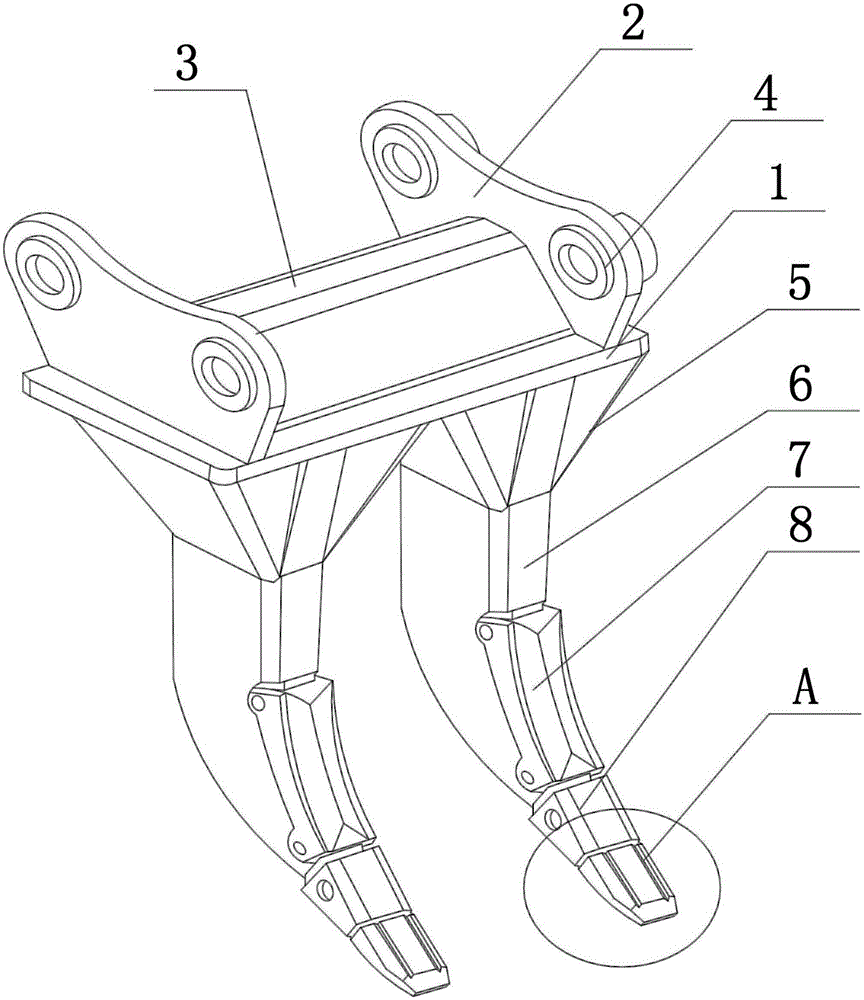

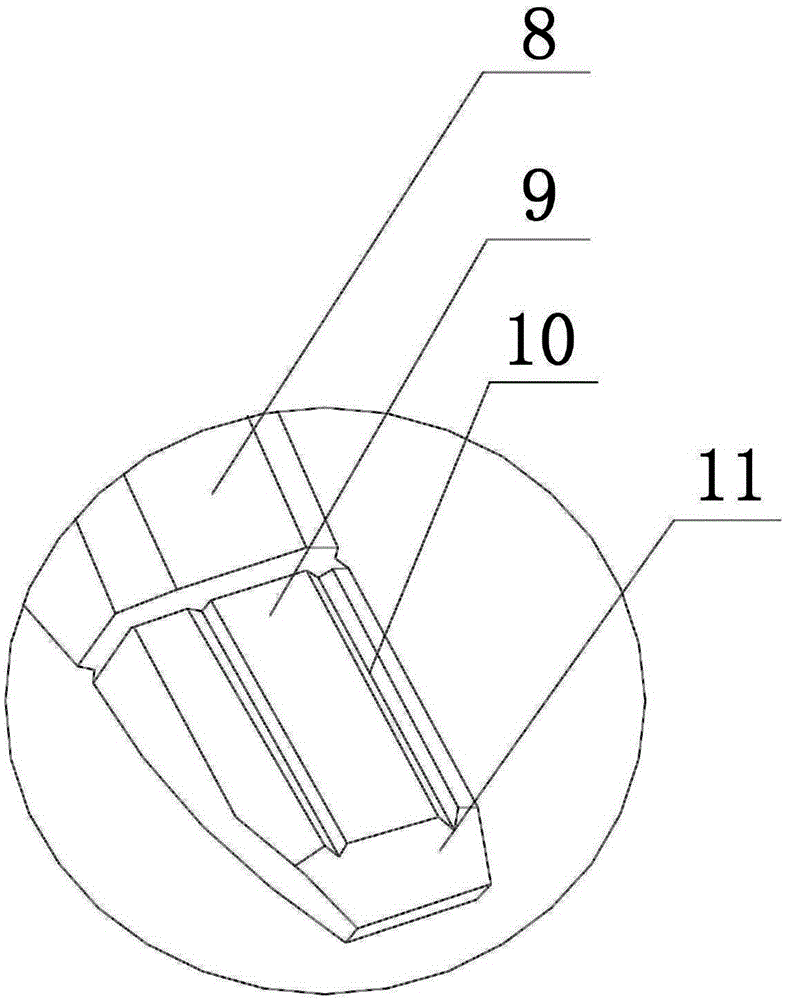

[0021] Such as figure 1 and figure 2 As shown, this embodiment includes a square connecting plate 1, ear plates 2 with shaft holes 4 are installed on both sides of the upper part of the connecting plate, and a trapezoidal reinforcing plate 3 is welded between the two ear plates 2, Weld two or more than two arc-shaped tooth bars 6 with bucket teeth 9 at the bottom middle position of the connecting plate 1, and connect with the outer wall of the tooth bar 6 at the square peripheral edge of the connecting plate 1 A reinforcement plate 5 is welded between them, and the distance between the upper ends of two adjacent gear rods 6 is 40-60 cm. An alloy sheath 7 is installed on the inner side of the arc-shaped curved surface of the gear rods 6 through a pin shaft. A tooth sleeve 8 is installed on the upper part of the bucket tooth 9 through a pin shaft, and two arc-shaped diversion grooves 10 are opened on the inner side wall of the lower part of the bucket tooth 9, and the diversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com