Assembled annular rebar buckling anchoring-connection concrete shear wall unilateral floor slab connecting structure

A concrete shear wall and connection structure technology, applied in walls, building components, building structures, etc., can solve the problems of difficult quality control, high production costs, and restrictions on the development of prefabricated shear wall structures, and achieve convenient connection and operation Excellent efficiency and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

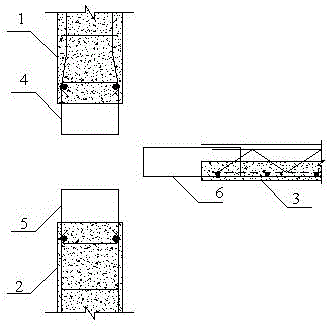

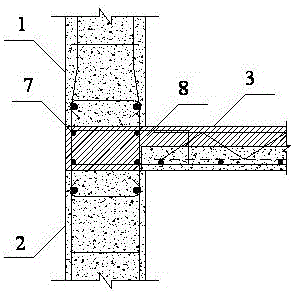

[0013] Such as Figure 1~2 As shown, a prefabricated ring reinforcement fastening and anchoring concrete shear wall unilateral floor connection structure disclosed by the present invention includes an upper outer wall panel 1, a lower outer wall panel 2 and a laminated floor 3 on one side, Wherein the upper exterior wall panel 1 and the lower exterior wall panel 2 are prefabricated annular reinforced concrete structures, and vertical annular steel bars are prefabricated in the vertical direction inside, and the upper and lower ends of the vertical annular steel bars extend to the outside of the upper and lower ends of the outer wall panels, The indwelling length is greater than 150 mm, and the laminated floor 3 is prefabricated with criss-crossing annular steel bars 6, and the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com