A support type anti-buckling low-relaxation friction anti-seismic damper

A technology of frictional damping and anti-buckling, which is applied in the direction of earthquake resistance, building types, protected buildings/shelters, etc., and can solve problems such as restrictions on the arrangement and use of dampers, unusable frictional dampers, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In view of the above objectives, the present invention aims to provide a damper for axially supporting force and capable of adjusting the frictional damping force.

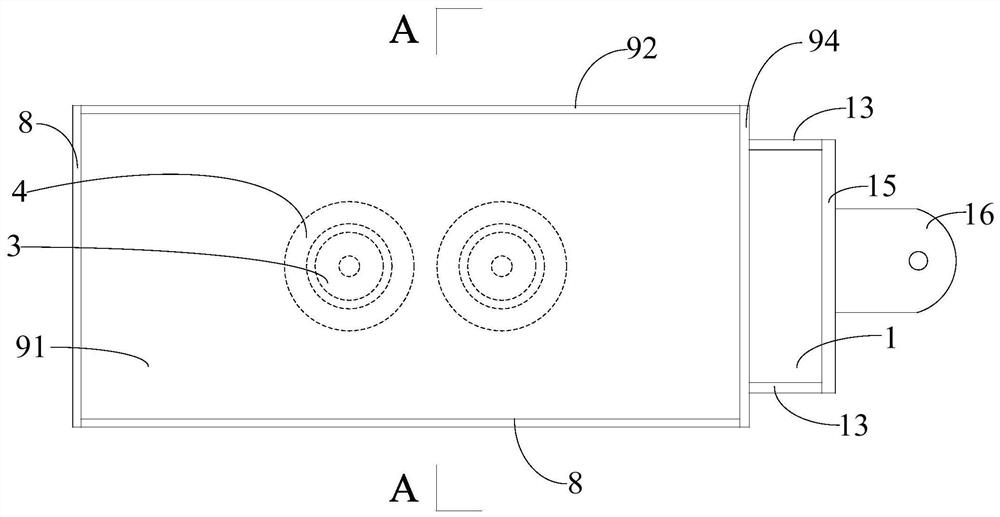

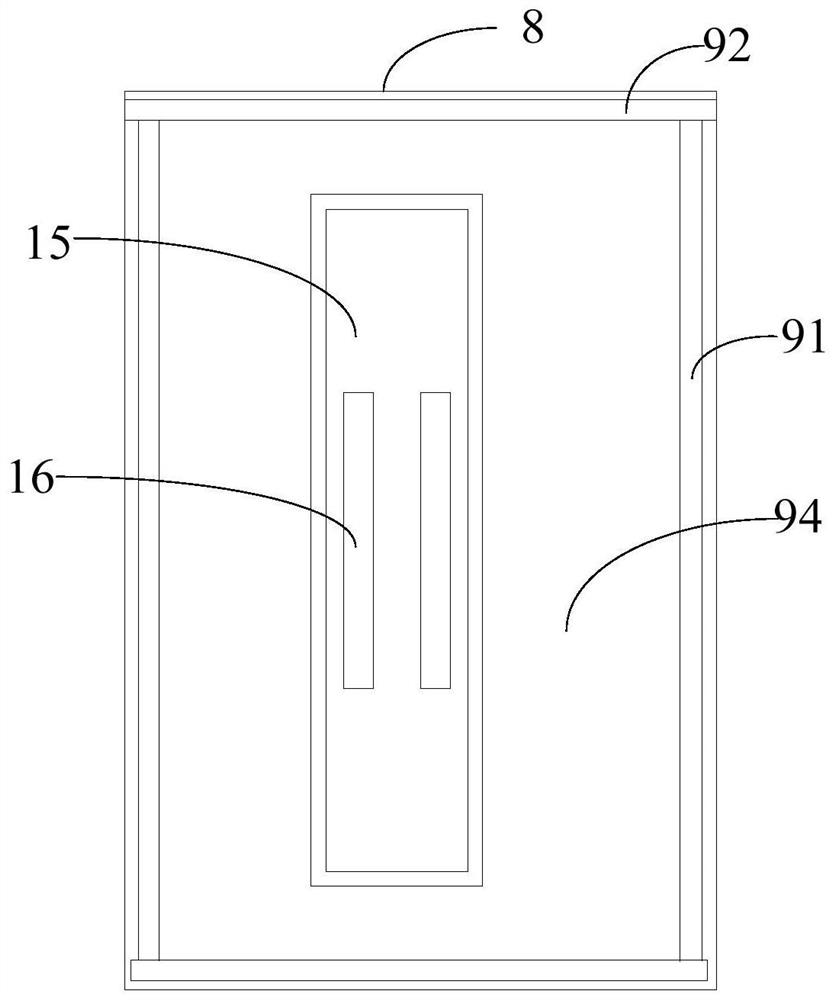

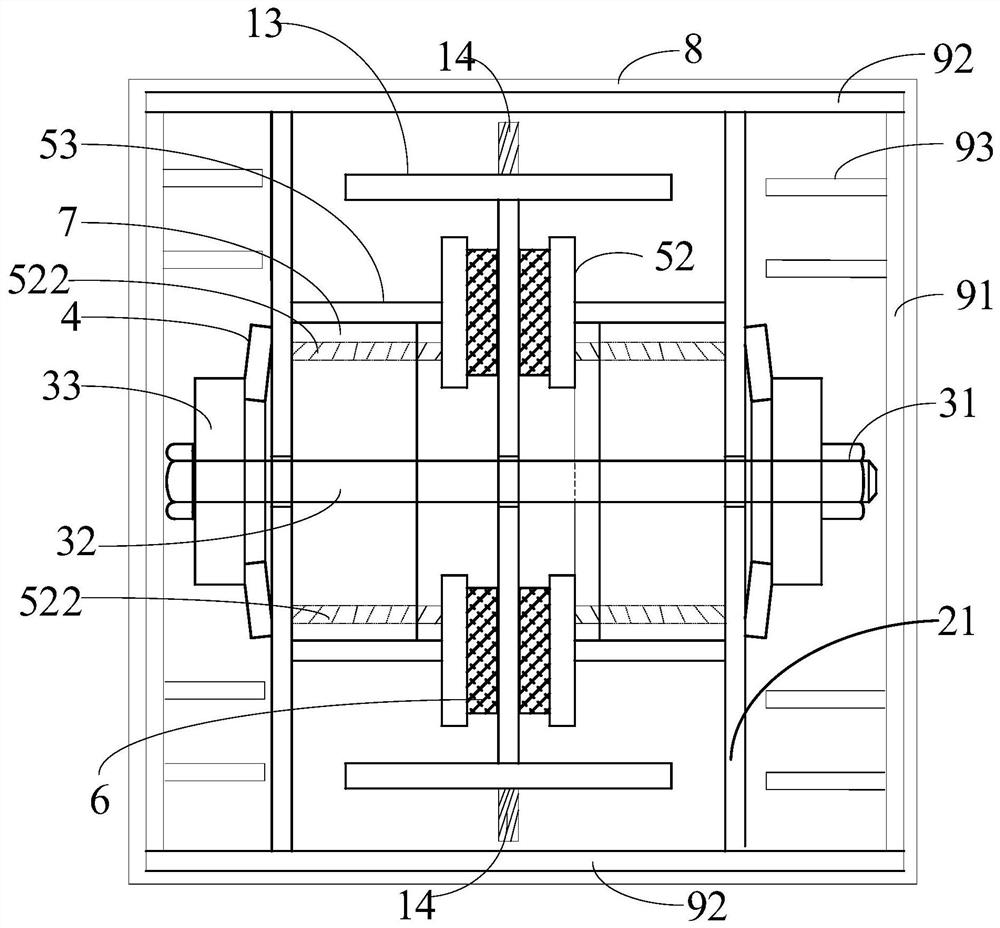

[0037] see figure 1 , figure 2 , image 3 as well as Figure 4, the present invention provides a support type anti-buckling low-relaxation friction type anti-seismic damper, provides a kind of anti-seismic friction damping force along the supporting axial direction, the friction damping force is very low with the wear of the friction damping layer 6 . In order to achieve this purpose, the support type anti-buckling low-relaxation friction anti-vibration damper of the present invention includes: a damping core plate 1, which is provided with an assembly hole 12; The outer clamping plates 21 on both sides of the plate and the connecting end plates 8 for connecting the external main body structure; the friction damping layer 6 is sandwiched between the outer clamping plate 21 and the damping core plate 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com