Steel bar truss deck and production process thereof

A technology of steel bar truss and production process, which is applied to floors, building components, buildings, etc., can solve the problems of large amount of steel binding work, long construction period, low construction efficiency, etc., so as to shorten the construction period, reduce the construction difficulty, and improve the construction The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

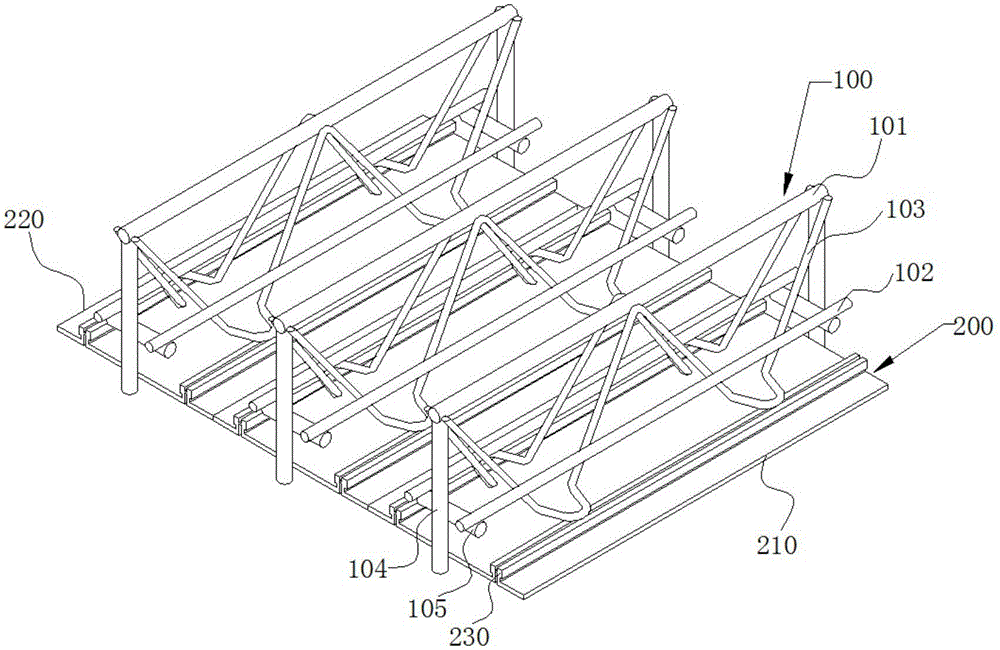

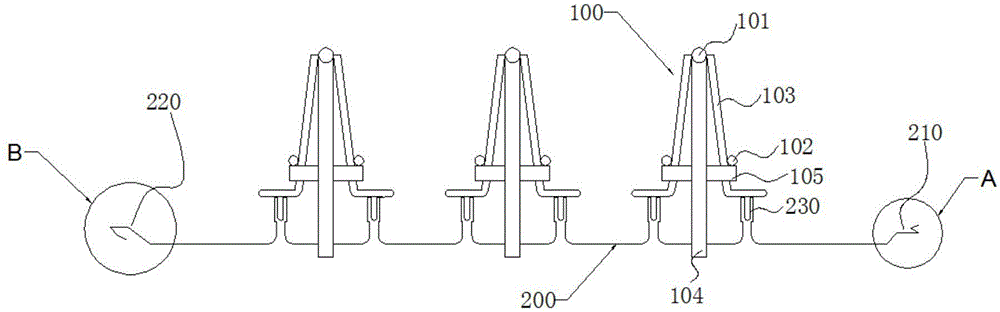

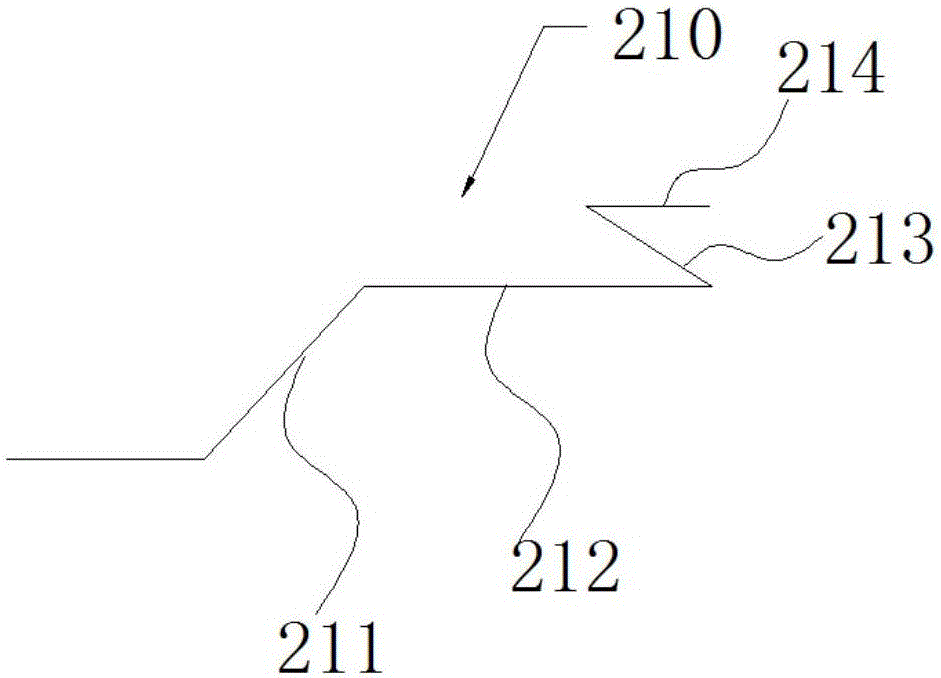

[0030] figure 1 Schematic diagram of the structure of the reinforced truss floor deck provided by Embodiment 1 of the present invention; figure 2 for figure 1 The schematic diagram of the left-view structure of the reinforced truss floor deck shown; image 3 for figure 1 Partial enlarged schematic diagram of A; Figure 4 for figure 1 Partial enlarged schematic diagram of B in middle; Figure 5 for figure 1 Schematic diagram of the structure of the welded rib shown; Figure 1-5 As shown, the steel bar truss floor deck provided by the embodiment of the present invention includes a steel bar truss 100 and a galvanized profiled steel plate 200. The upper surface of the profiled steel plate 200 is connected by spot welding, one side of the length direction of the galvanized profiled steel plate 200 is provided with a first bayonet socket 210, and the other side of the length direction of the galvanized profiled steel sheet 200 is provided with a second bayonet socket 220 ,...

Embodiment 2

[0049] This embodiment provides a production process for a reinforced truss floor deck. The production process includes the following steps: welding the steel bar truss 100 and the galvanized profiled steel plate 200 into one by resistance spot welding to obtain a reinforced truss floor deck .

[0050] By welding the steel bar truss 100 and the galvanized profiled steel plate 200 into one body, the workload of steel bar binding on the construction site is simplified, multiple floors can be constructed at the same time, and the construction efficiency is improved. In addition, because the steel bar truss 100 is prefabricated in advance, the steel bars on the floor deck of the steel bar truss are evenly arranged, the stress mode is reasonable, the crack resistance is excellent, and it is safer and more reliable. At the same time, the height of the steel truss floor slab can also be adjusted by adjusting the height of the steel truss 100 to meet the needs of floors with different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com