Purifying and liquefying process for re-injecting oilfield CO2 flooding produced gas

A gas production and process technology, applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of high initial investment and high energy consumption in operation, and achieve the effect of recycling and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation plan

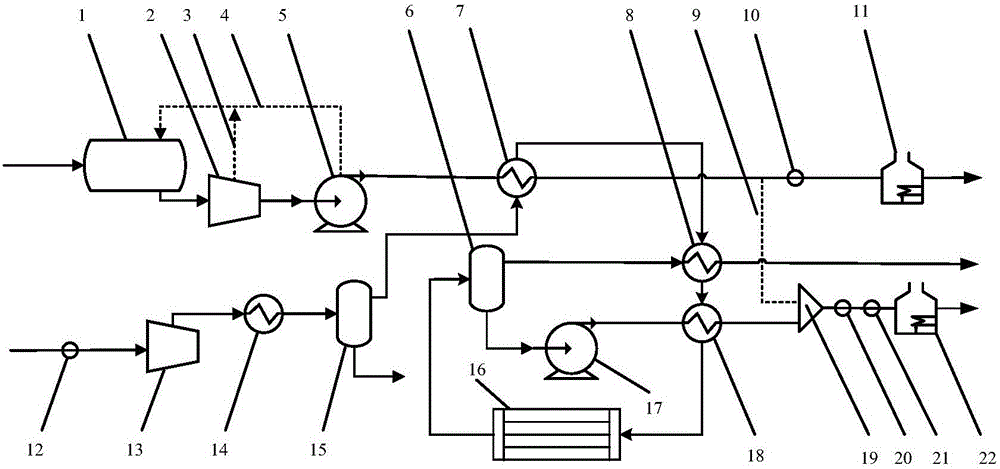

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

[0038] (1) Oilfield CO 2 The gas produced by flooding undergoes pretreatment modules such as solid removal, oil removal, and dehydration to deeply remove tiny solid particles and water therein, and is detected by a water dew point detector (12) to meet the requirements of subsequent processing.

[0039] (2) Pressurizing the pretreated produced gas with a compressor (13), and cooling and dehydrating the produced gas with an air cooler (14) and a gas-liquid separator (15).

[0040] (3) The treated high-pressure gas passes through the heat exchanger (7) and the liquid CO injected into the oil field 2 Fully heat exchange, so that the CO in the output gas 2 liquefaction. At the same time, the liquid is separated by the gas-liquid separator (6), and the gas is transported outside through the pipeline, because the CH in the gas 4 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com