Novel vertical shaft heading machine and construction method thereof

A technology for roadheaders and shafts, which is applied to shaft equipment, sinking, and earthwork drilling and mining. It can solve problems such as inability to complete excavation at one time, low drilling efficiency, and construction impact, so as to improve overall construction efficiency and reduce downhole construction. The number of personnel and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

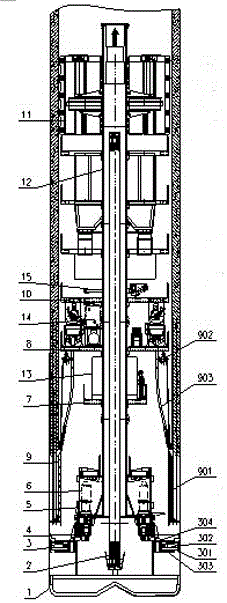

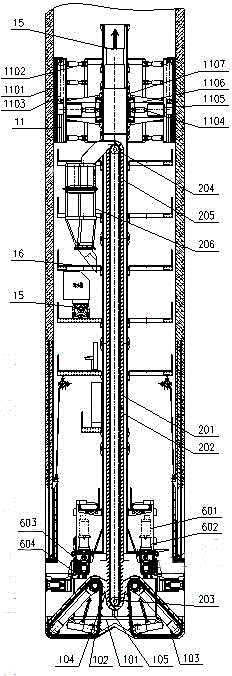

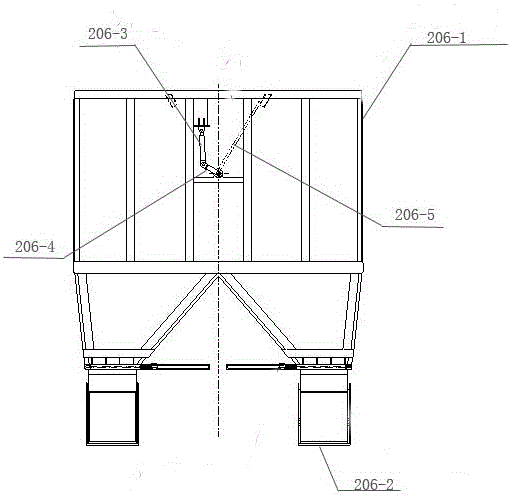

[0028] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5, serial number in the figure: 1 is the cutter head, 2 is the slag discharge device, 3 is the stabilizer, 4 is the one-story platform, 5 is the support platform, 6 is the main driving device, 7 is the second-story platform, 8 is the three-story platform , 9 is the shaft wall construction device, 10 is the four-story platform, 11 is the shoe propulsion device, 12 is the column, 13 is the control system, 14 is the hydraulic system, 15 is the ventilation and drainage system, 16 is the auxiliary construction system, 101 is the knife Disk main body, 102 is cutter, 103 is slag cleaning device, 104 is slag collecting device, 105 is swivel joint, 103-1 is scraper, 103-2 is scraper chain, 103-3 is reversing wheel, 103-4 103-5 is the driving wheel, 103-6 is the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com