Backfill grouting restoring draw shaft process of metal mine

A technology of chute and grouting, which is applied in the direction of filling, shaft lining, mining equipment, etc. It can solve the problems of chute wall rock damage, chute penetration, and collapse, etc., and achieves simple configuration method, wide application range, and construction personnel little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

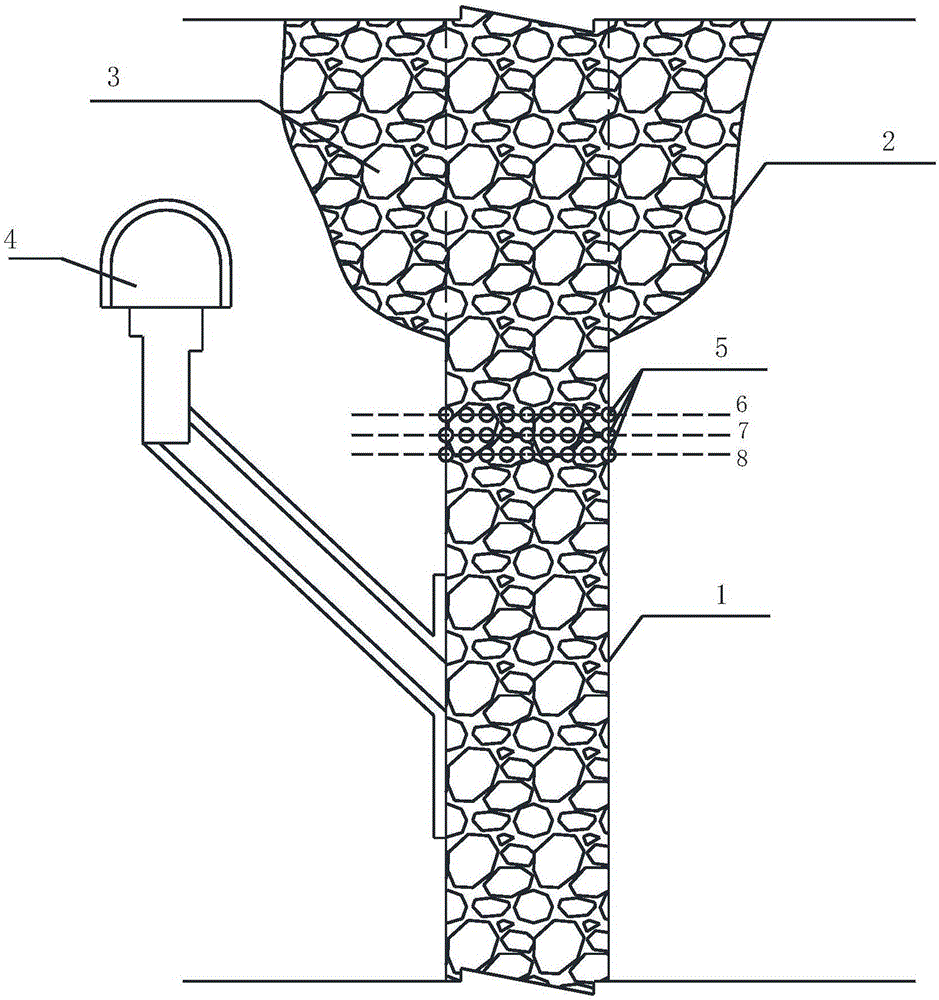

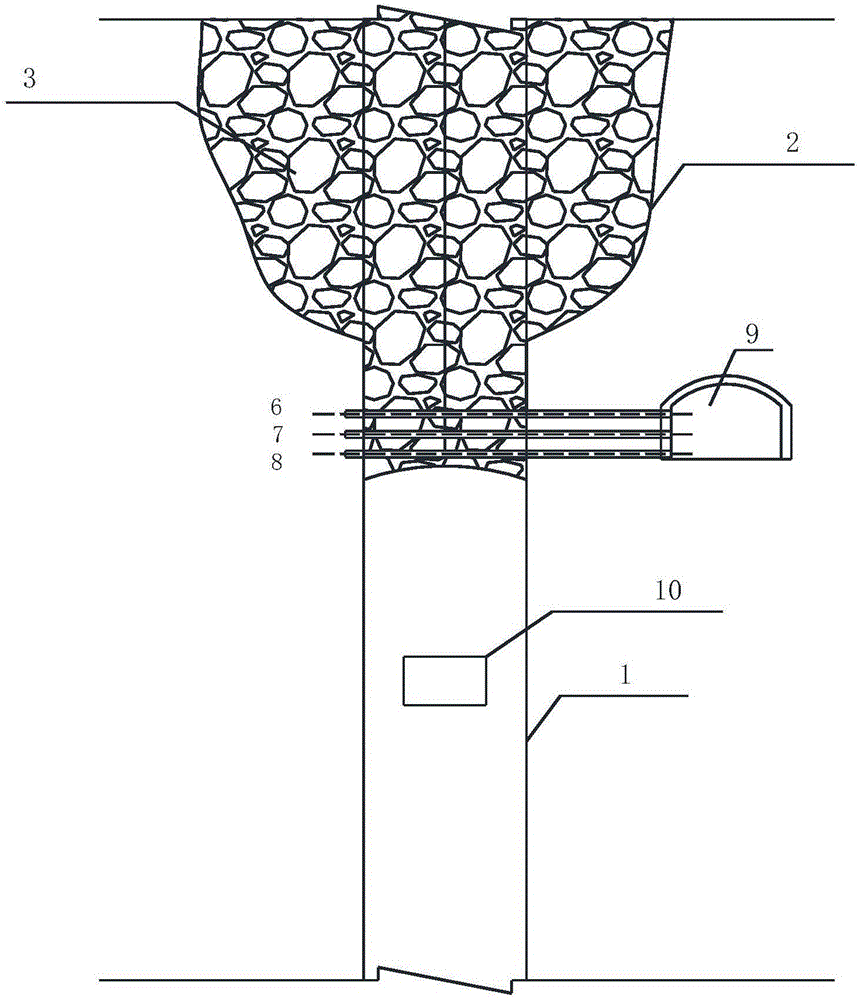

[0026] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0027] In this embodiment, the process of backfilling the metal mine with bulk grouting and repairing the chute includes the following steps:

[0028] (1) Investigate the damaged area of the surrounding rock of the chute, and fill the entire shaft of the damaged chute with bulk materials;

[0029] The bulk material is ballast or crushed stone. The detailed specifications of the bulk material are: the particle size is 28-63mm, the crushing rate of the bulk aggregate is 9%-14%, and the permeability coefficient of the bulk ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com