A preparation system and method for phase change material temperature-controlled cell-coating inhibitor

A phase change material and preparation system technology, which is applied in the field of phase change material temperature-controlled coating inhibitor preparation system, can solve problems such as poor stability, short resistance life, and inability to effectively control the spontaneous combustion area of the goaf, so as to achieve high-efficiency production Effects of processing, overcoming easy failure, and inhibiting spontaneous combustion of coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

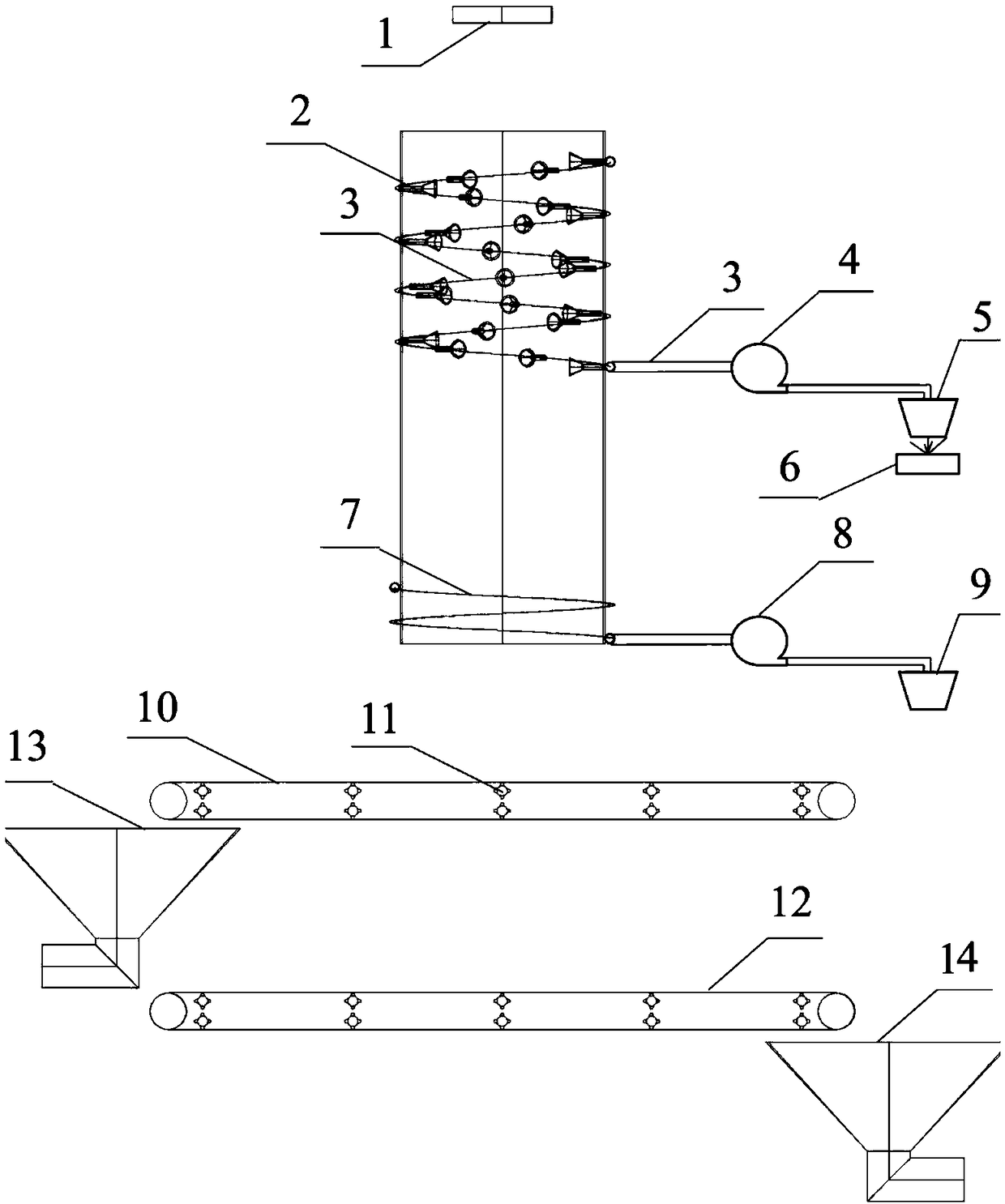

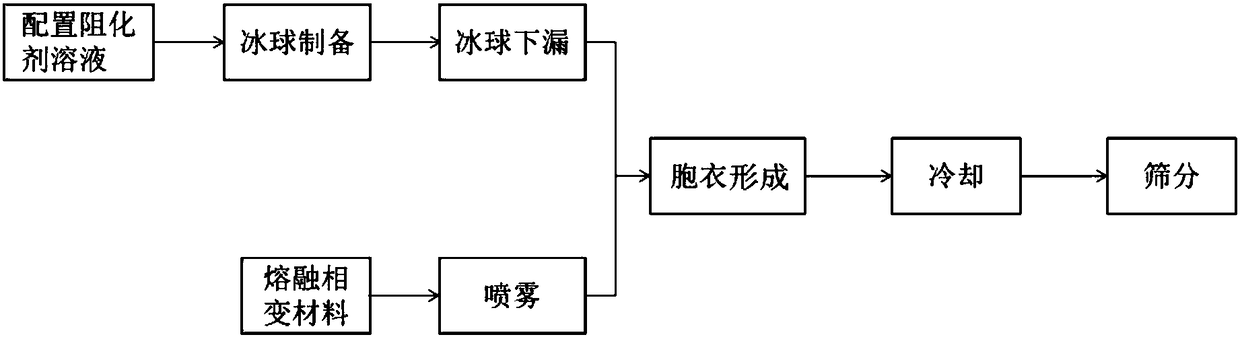

[0026] Such as figure 1 As shown, a phase-change material temperature-controlled cell-coating inhibitor preparation system includes an ice ball preparation unit, a drain unit, a melting phase-change material unit, a spray unit, a cooling unit, and a screening unit.

[0027] Wherein, the ice hockey preparation unit includes a spherical silica gel mold and a freezing chamber.

[0028] The lower drain unit includes a lower drain disc 1, which is equipped with a drive mechanism; the bottom of the lower drain disc 1 is provided with holes, and the lower drain disc 1 can shake back and forth, left and right, and ice ball particles can drop from the holes of the lower drain disc 1 one by one.

[0029] The melting phase change material unit includes a heating furnace 6 and a melting tank 5 , and the melting tank 5 is placed on the heating furnace 6 .

[0030] The spray unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com