Fault diagnosis and online monitoring method of wind turbine main control system based on data-driven

A main control system, data-driven technology, applied in wind turbine monitoring, engines, wind turbines, etc., can solve the problems of complex implementation and cumbersome methods, and achieve the goal of improving power generation efficiency, economic benefits, and maintenance and repair efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

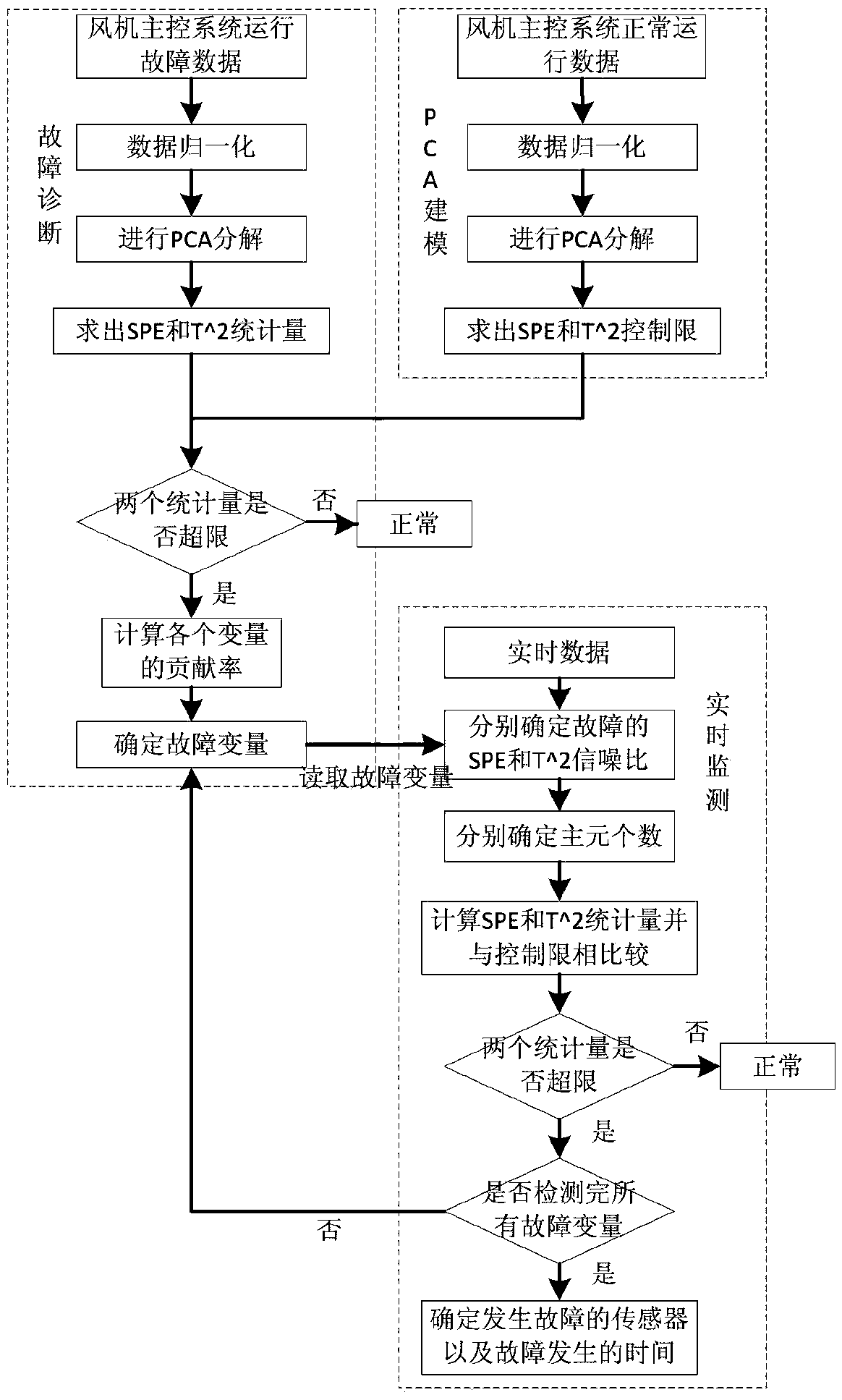

[0060] Such as figure 1 As shown, the data-driven wind turbine main control system fault diagnosis and online monitoring method includes PCA modeling of the normal operation data of the wind turbine main control system, fault diagnosis of the wind turbine main control system operation fault data and real-time There are three stages of real-time monitoring of operating data, including the following steps:

[0061] Step 1: When the main control system of the fan is running normally, periodically sample the variables of the main control system of the main control system of the fan, and perform data processing on the sampled data to calculate T 2 Control Limits and SPE Control Limits:

[0062] Step 1-1: When the main control system of the wind turbine is running normally, the data acquisition equipment periodically samples n main control system variables during the operation of the main control system of the wind turbine, and samples m times to obtain the normal sampling matrix X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com