A method and device for fault monitoring of an injection valve

A technology of fault monitoring and injection valve, which is applied in the direction of measuring device, mechanical valve test, engine test, etc., can solve the problems that the failure of injection valve cannot be monitored, and the speed of damage can be accelerated, so as to ensure timely detection and elimination, and guarantee Safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

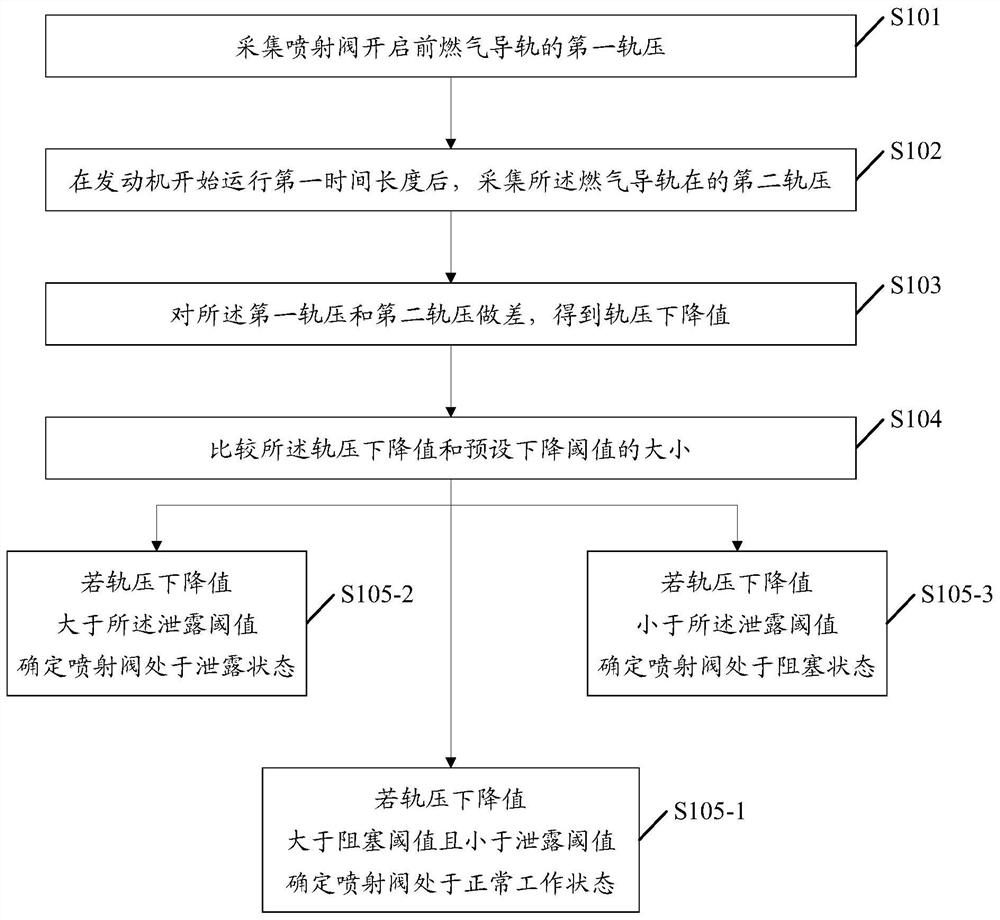

Method used

Image

Examples

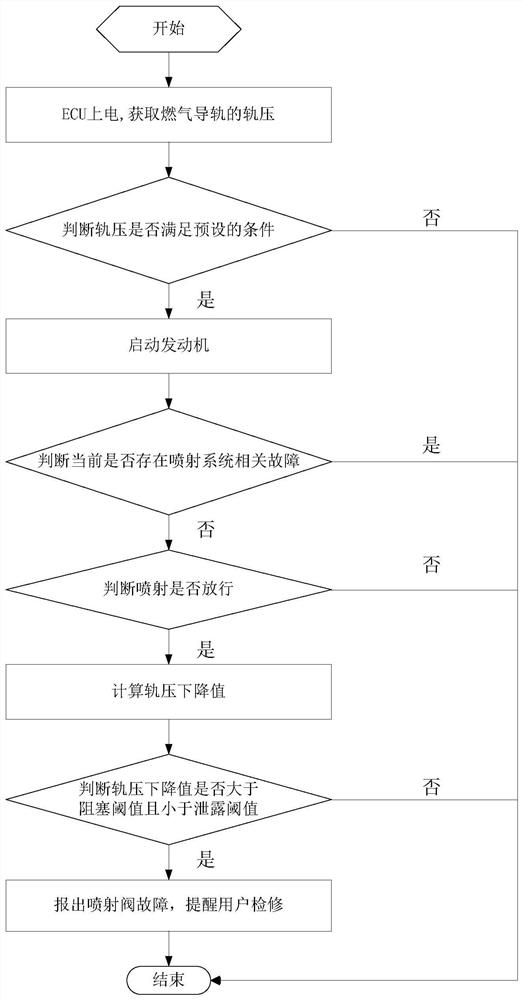

Embodiment Construction

[0057]The injection valve is a part of the gas fuel engine, which is used to inject fuel into the combustion chamber for combustion. Therefore, when the injection valve is damaged, it will directly cause the engine to fail to work. And because the injection valve is directly connected to the combustion chamber, it will be in a state of high temperature and vibration during work, so it is not convenient to directly install sensors inside the injection valve for fault monitoring. Therefore, at present, the failure of the injection valve is basically monitored by the elimination method. If the engine power is insufficient but no failure of other engine components is detected, it indicates that the injection valve has a certain probability of failure, and further monitoring of the engine can determine and eliminate the failure of the injection valve.

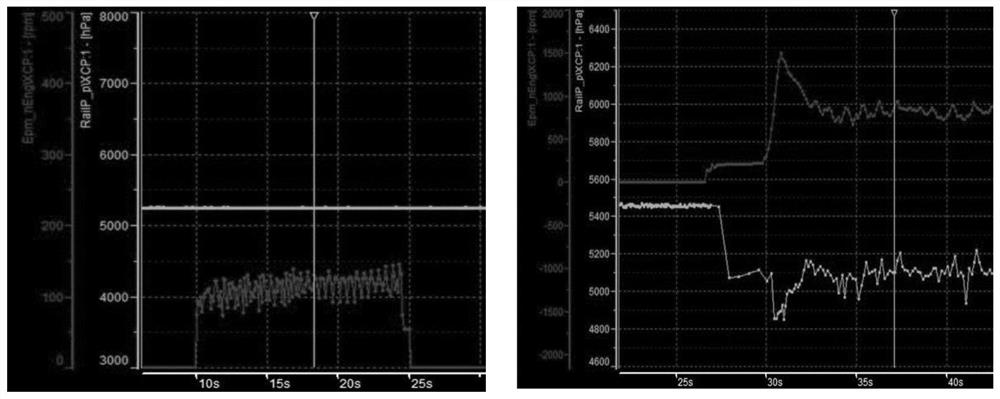

[0058] However, the electronic control system of the engine also has closed-loop control systems such as closed-loop control of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com