Bearing cooling device

A cooling device and bearing technology, applied in the direction of bearing cooling, bearing components, shafts and bearings, etc., can solve the problems of increasing the water inlet flow of the cooling body, increasing the friction coefficient of the bearing bush, poor lubrication, etc., to solve the problem of frequent alarm and shutdown Problems or problems of burning pads, the friction coefficient of bearing pads is kept stable, and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

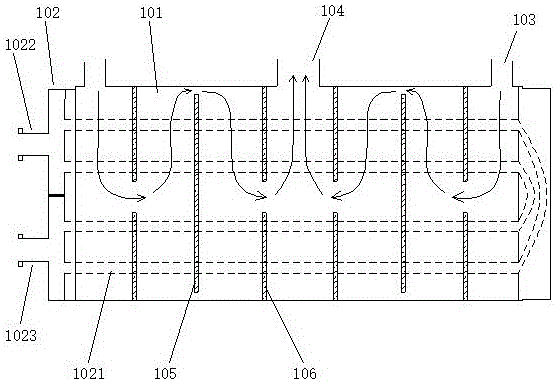

[0068] A bearing cooling device such as Figure 4 As shown, it includes a cooling chamber 1 and a cooling body 2, the cooling body 2 is located in the cooling chamber 1, and the cooling body 2 is coaxial with the cooling chamber 1; the cooling chamber 1 includes two hot oil inlets 11 and a cooling The oil outlet 12, the two thermal oil inlets 11 are respectively the first thermal oil inlet 111 and the second thermal oil inlet 112, the first thermal oil inlet 111 and the second thermal oil inlet 112 are respectively located at both ends of the cooling chamber 1, and the cold oil outlet 12 is located in the middle of the cooling chamber 1;

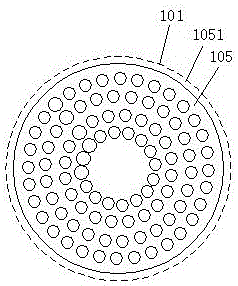

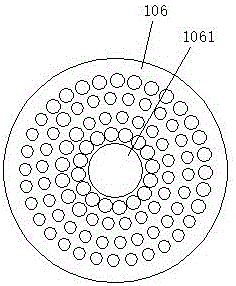

[0069] Such as Figure 4 As shown, the cooling body 2 includes a cooling pipe 21, a water inlet flange 22, an outlet flange 23, a bottom hole flow passage partition 3 and a top hole flow passage partition 4, and the cooling pipe 21 includes a water inlet 211 and a water outlet 212 , the water inlet 211 is connected to the water inlet flang...

Embodiment 2

[0076] A bearing cooling device such as Figure 7 As shown, it includes a cooling chamber 1 and a cooling body 2, the cooling body 2 is located in the cooling chamber 1, and the cooling body 2 is coaxial with the cooling chamber 1; the cooling chamber 1 includes two hot oil inlets 11 and a cooling The oil outlet 12, the two thermal oil inlets 11 are respectively the first thermal oil inlet 111 and the second thermal oil inlet 112, the first thermal oil inlet 111 and the second thermal oil inlet 112 are respectively located at both ends of the cooling chamber 1, and the cold oil outlet 12 is located in the middle of the cooling chamber 1;

[0077] Such as Figure 7 As shown, the cooling body 2 includes a cooling pipe 21, a water inlet flange 22, an outlet flange 23, a bottom hole flow passage partition 3 and a top hole flow passage partition 4, and the cooling pipe 21 includes a water inlet 211 and a water outlet 212 , the water inlet 211 is connected to the water inlet flang...

Embodiment 3

[0085] A bearing cooling device such as Figure 8 As shown, it includes a cooling chamber 1 and a cooling body 2, the cooling body 2 is located in the cooling chamber 1, and the cooling body 2 is coaxial with the cooling chamber 1; the cooling chamber 1 includes a hot oil inlet 11 and a cold oil The oil outlet 12, the hot oil inlet 11 and the cold oil outlet 12 are respectively located at both ends of the cooling chamber 1;

[0086] Such as Figure 8 As shown, the cooling body 2 includes a cooling pipe 21, a water inlet flange 22, an outlet flange 23, a bottom hole flow passage partition 3 and a top hole flow passage partition 4, and the cooling pipe 21 includes a water inlet 211 and a water outlet 212 , the water inlet 211 is connected to the water inlet flange 22, and the water outlet 212 is connected to the water outlet flange 23, and the water inlet flange 22 and the water outlet flange 23 are located on the side of the cooling chamber 1; the cooling body 2 includes at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com