Coupling device for elimination of backlash

A technology of coupling device and side clearance, applied in the direction of coupling, elastic coupling, mechanical equipment, etc., can solve the problems of small size and complicated manufacturing, and achieve the effect of easy production and installation, low cost and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

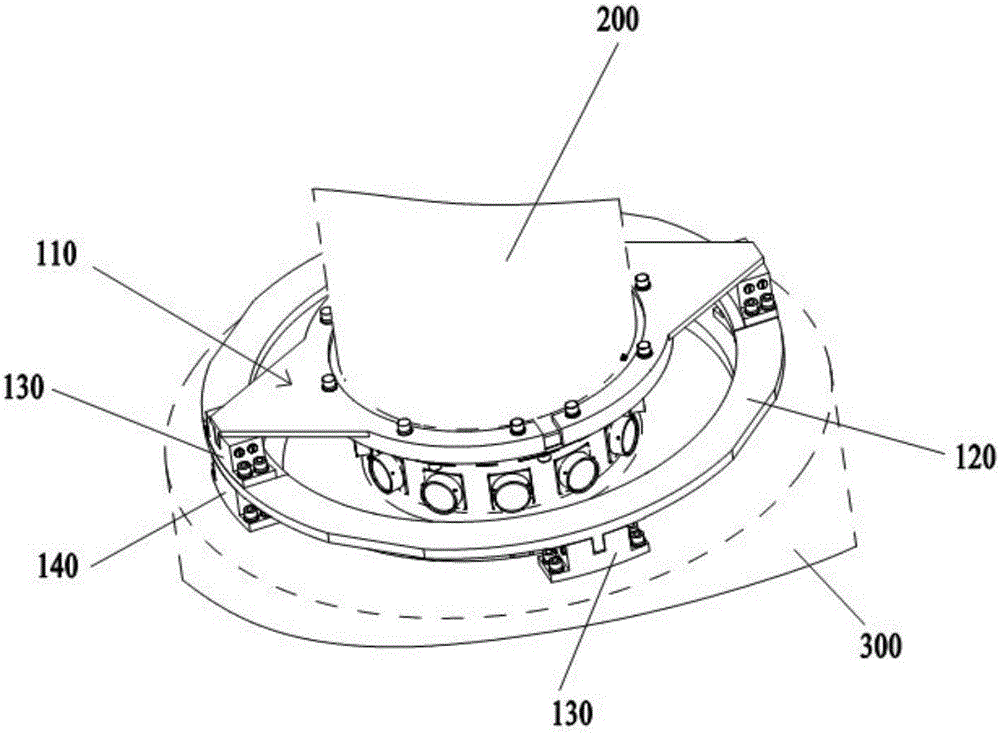

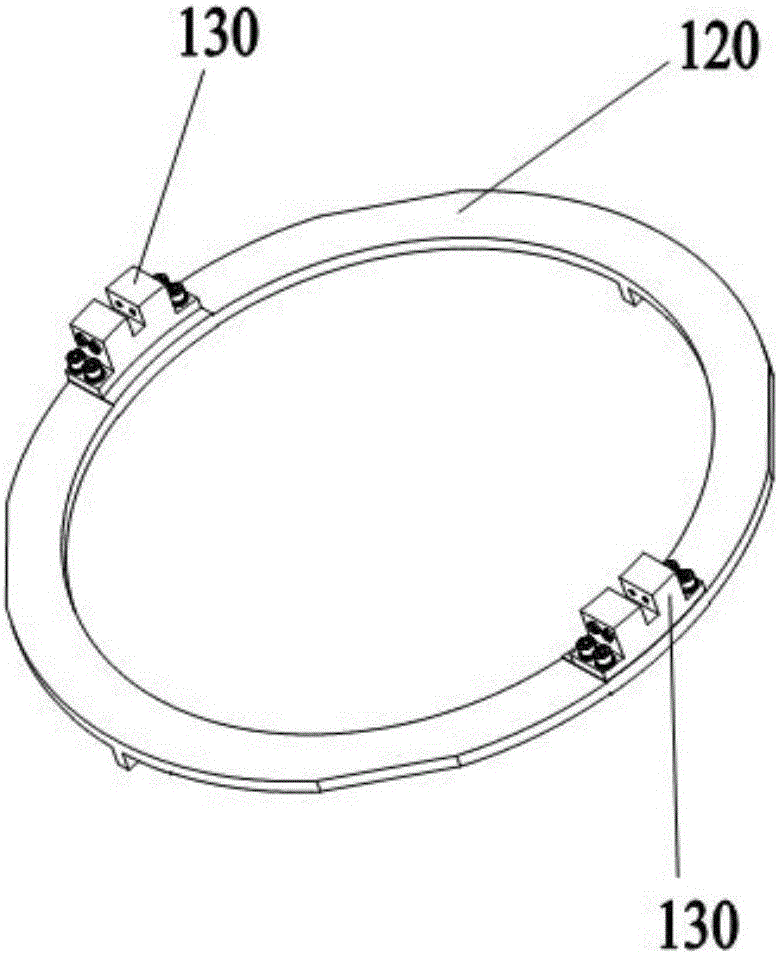

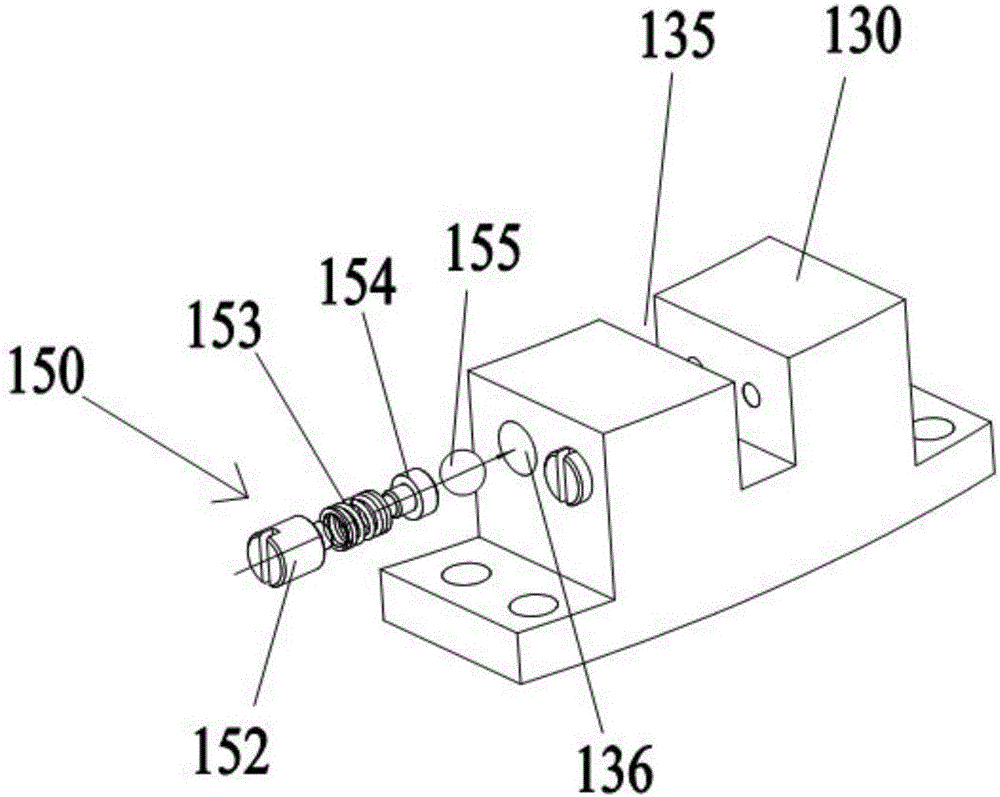

[0028] like Figure 1 to Figure 6 As shown, the coupling device for eliminating backlash provided by the present invention includes a dial 110 and a sliding plate 120, the dial 110 is installed on the output shaft 200, and the lower surface of the dial 110 is provided with several dial flanges 1156 , the upper surface of the sliding plate 120 is equipped with a number of sliding seats 130 corresponding to the dial flanges 1156 one by one, the upper surface of the sliding seat 130 is provided with grooves 135, and the dial flanges 1156 are snapped into the grooves of the corresponding sliding seats 130 within 135;

[0029] The lower surface of the sliding plate 120 is evenly provided with several sliding plate flanges 125, and the input shaft 300 is equipped with a number of sliding seats 130 corresponding to the sliding plate flanges 125 one by one, and the sliding plate flanges 125 are clamped on the corresponding sliding seats 130. In the groove 135.

[0030] As a possible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com