Flying saucer type LED lamp assembly

An LED lamp assembly and LED lamp panel technology, applied in the field of flying saucer LED lamps, can solve the problems of shortened service life of the LED lamp panel, erosion and damage of the LED lamp panel circuit, difficulty in replacing the LED lamp panel, etc., and achieves a beautiful and good overall structure. Waterproof, easy-to-separate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

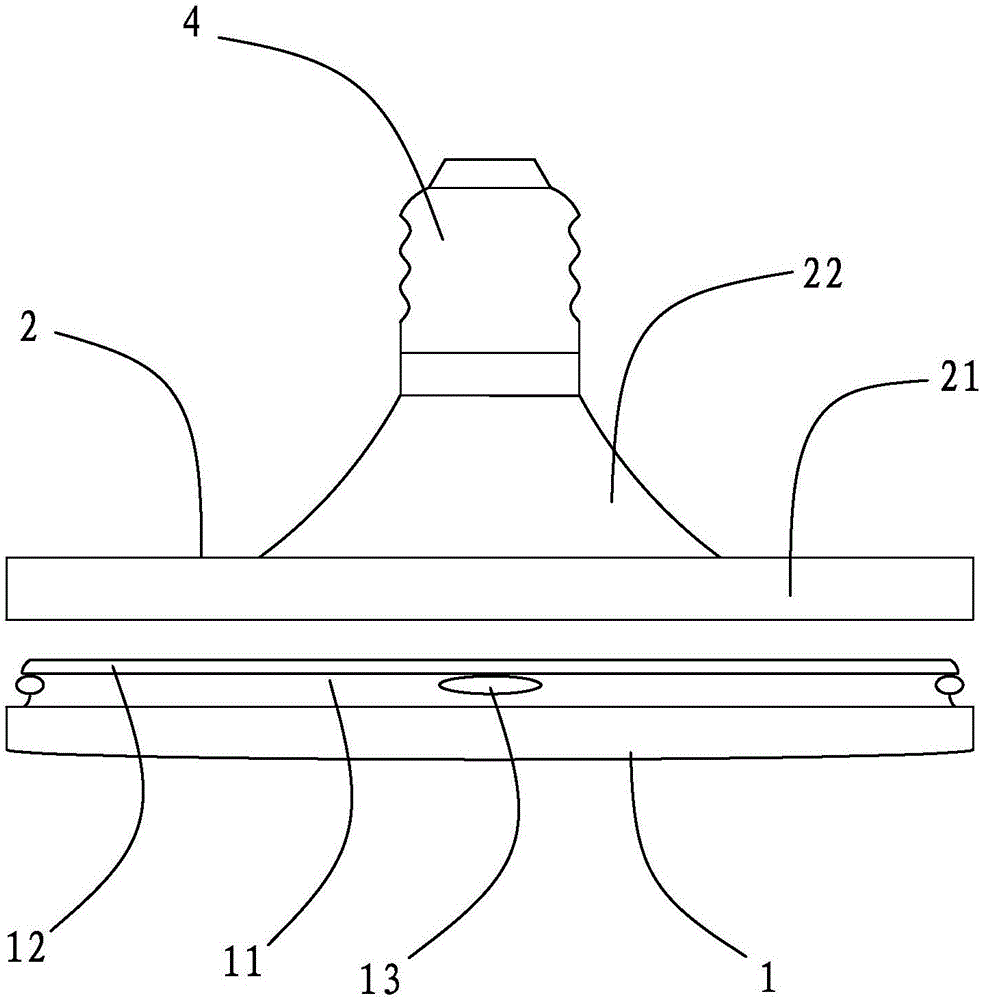

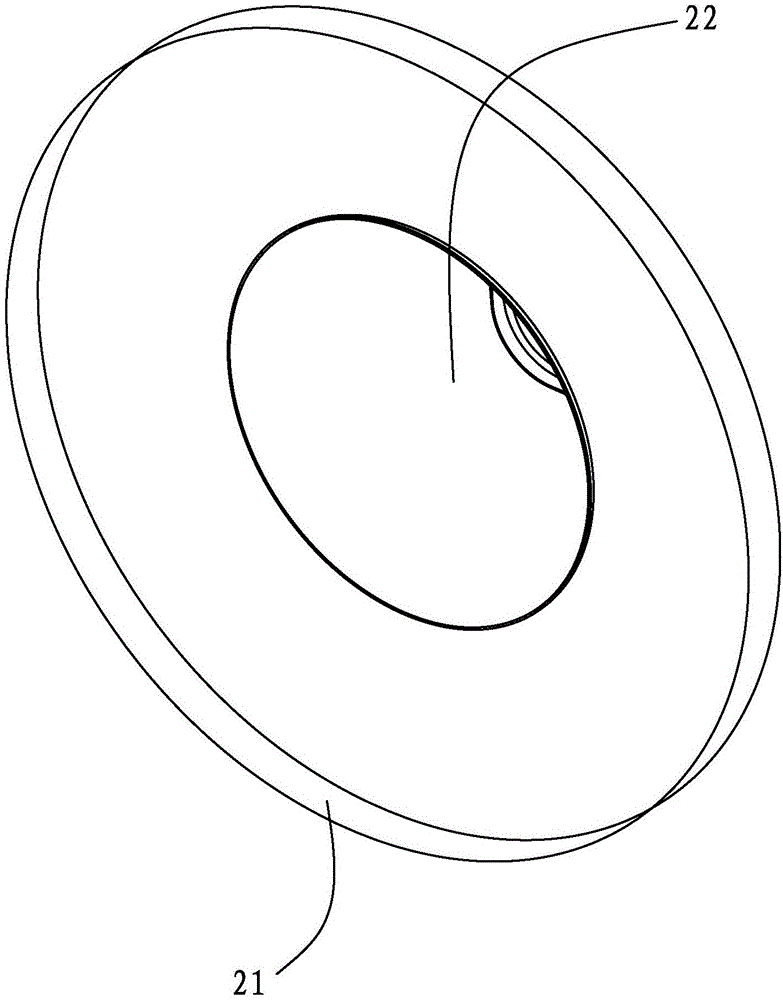

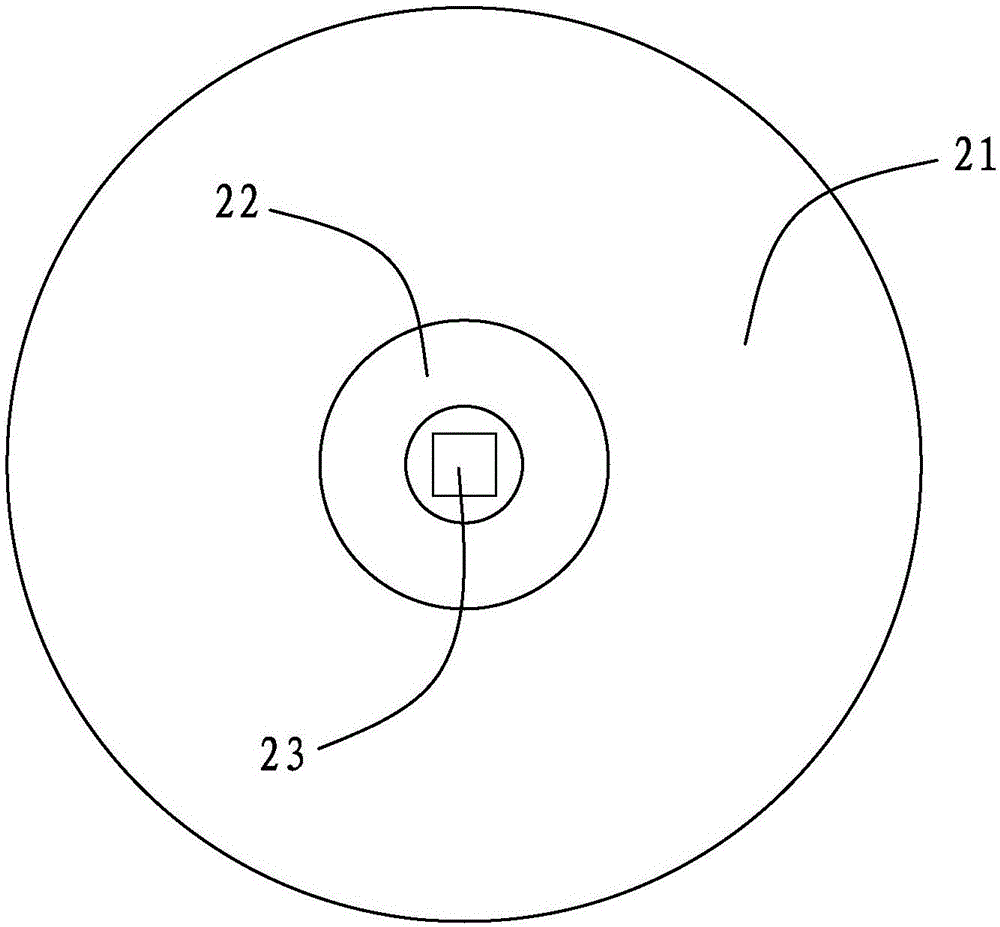

[0019] refer to Figures 1 to 2 , a flying saucer type LED lamp assembly, including a lampshade 1, a lamp holder 2, an LED lamp panel 3, a drive assembly and a connector 4, the lampshade 1 and the connector 4 are arranged on the upper and lower sides of the lamp holder 2, and the lamp holder 2 includes a circle The disc-shaped housing 21 is provided with inner curling on the lower edge of the circumference of the housing 21, and the entire lamp holder 2 is formed by pressing a thin plate. The upper side of the lampshade 1 is provided with a flange 11 adapted to the inner ring of the housing 21. The upper edge of the flange 11 extends outward from the outer collar 12. The lampshade 1 and the lamp holder 2 pass through the gap between the flange 11 and the housing 21. The fit and the fit between the outer collar 12 and the inner curling are fixed, and the flange 11 on the lower side of the outer collar 12 is provided with four smooth protrusions 13 along the circumference, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap