Combustion energy-saving compound control device

A composite control and control system technology, applied in the combustion method, control combustion, combustion equipment and other directions, can solve the problems of reducing fly ash and fly ash carbon content, high boiler combustion efficiency, etc., to reduce fly ash carbon content. , The effect of improving thermal efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

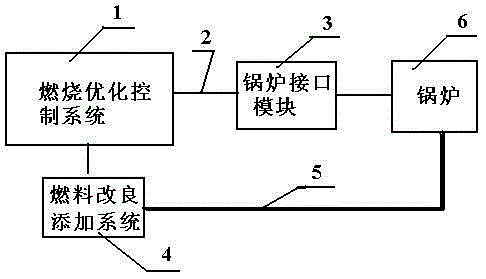

[0021] see figure 1 As shown, the present invention includes a combustion optimization control system 1, a boiler 6 and a fuel improvement and addition system 4, the combustion optimization control system 1 and the boiler 6 are connected through a boiler interface module 3, and the fuel improvement and addition system 4 is connected through a signal line 2 is connected with the combustion optimization control system 1, and the fuel improvement adding system 4 is connected with the boiler 6 through the transmission line 5, and a control unit is arranged in the boiler 6.

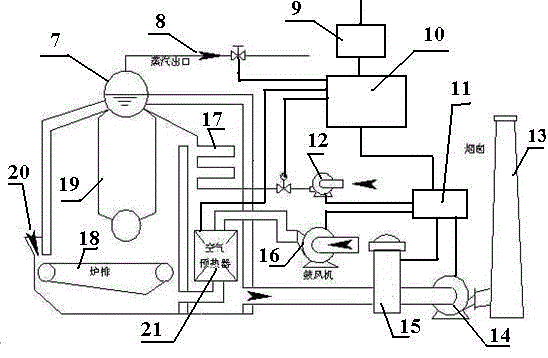

[0022] refer to figure 2 As shown, the boiler 6 includes a control system 9 , a data acquisition system 10 and an air preheating device 21 . The control system 9 is connected to the boiler interface module 3 through a signal line 2 and can communicate with the combustion optimization control system 1 . The working principle of the boiler 6 is: the combustible coal passed through the fuel improvement and addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com