Biomass coal briquetting system

A biomass and briquette technology, applied in waste fuel, petroleum industry, solid fuel, etc., can solve problems such as unseen and consumed metal and mineral resources, environmental damage, etc., to improve production efficiency, purify the surrounding environment, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

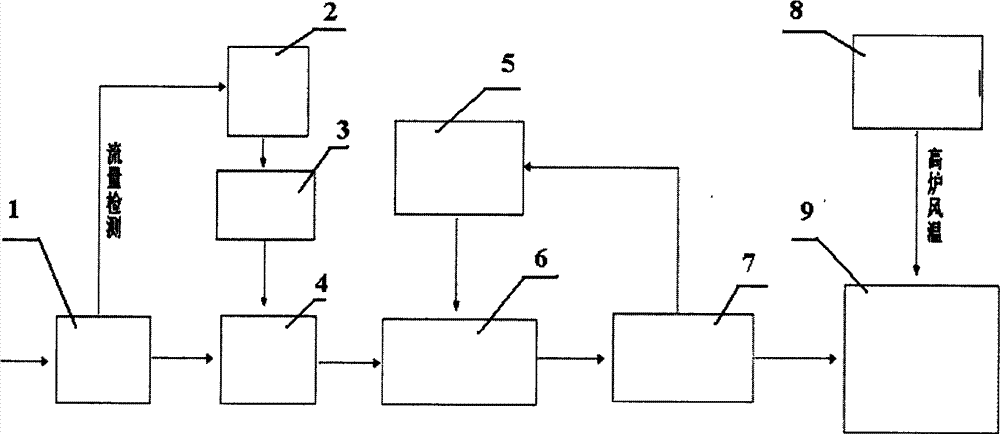

[0021] see figure 1 As shown, the present invention includes a biomass input system 1, a conveyor belt system 4, a blast furnace 9 and a predictive optimization control module 8, and a modifier control unit is arranged between the biomass input system 1 and the conveyor belt system 4, and the modifier control The unit includes spray volume control module 2 and modifier module 3 . A heating system is provided between the conveyor belt system 4 and the blast furnace 9 , and the heating system includes an infrared heating system 6 , a temperature control system 5 and a constant temperature biomass module 7 . The predictive optimization control module 8 is connected with the biomass input system 1 , the conveyor belt system 4 , the heating system, the improver control unit, and the blast furnace 9 through signal lines.

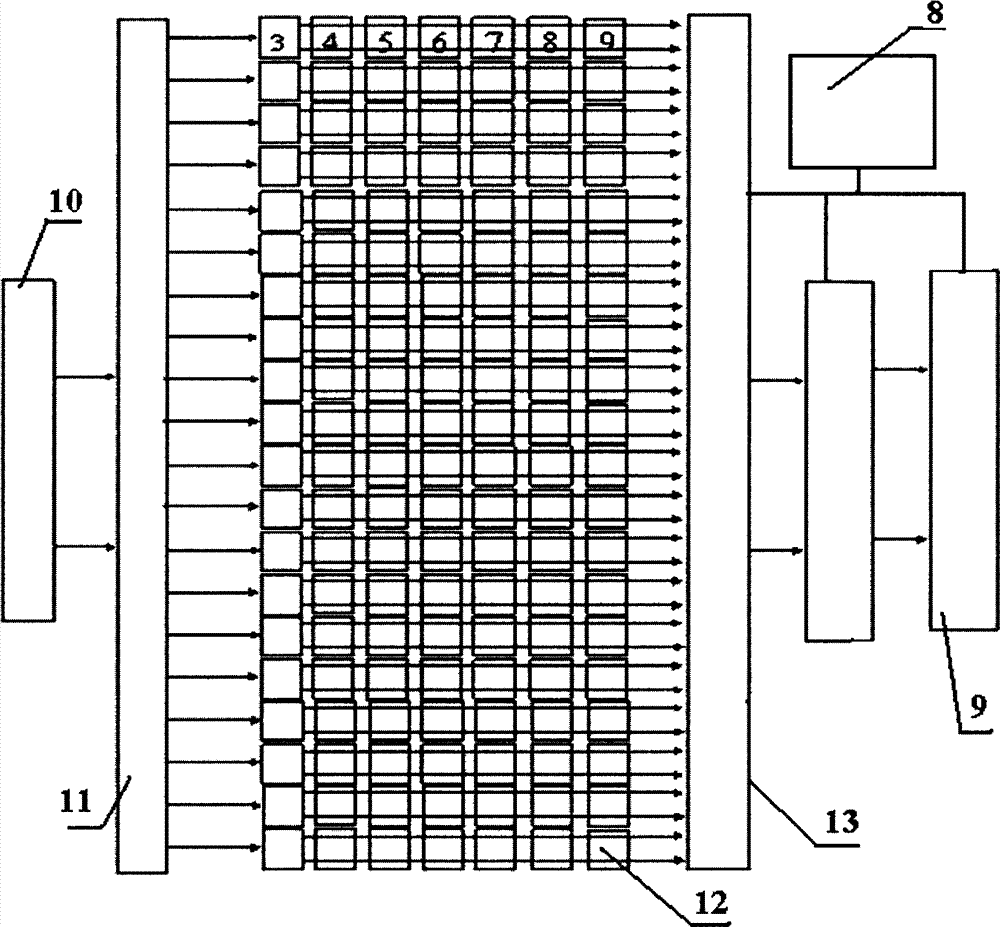

[0022] see figure 2 As shown, the conveyor belt system 4 of the present invention includes a biomass pool 10, a collecting and distributing platform 11, a bran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com