Roof-top unit

A roof machine and fan technology, which is used in household heating, space heating and ventilation details, heating methods, etc., can solve the problems of easy resonance, loud noise, and easily damaged equipment, so as to avoid severe resonance, reduce noise, The effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

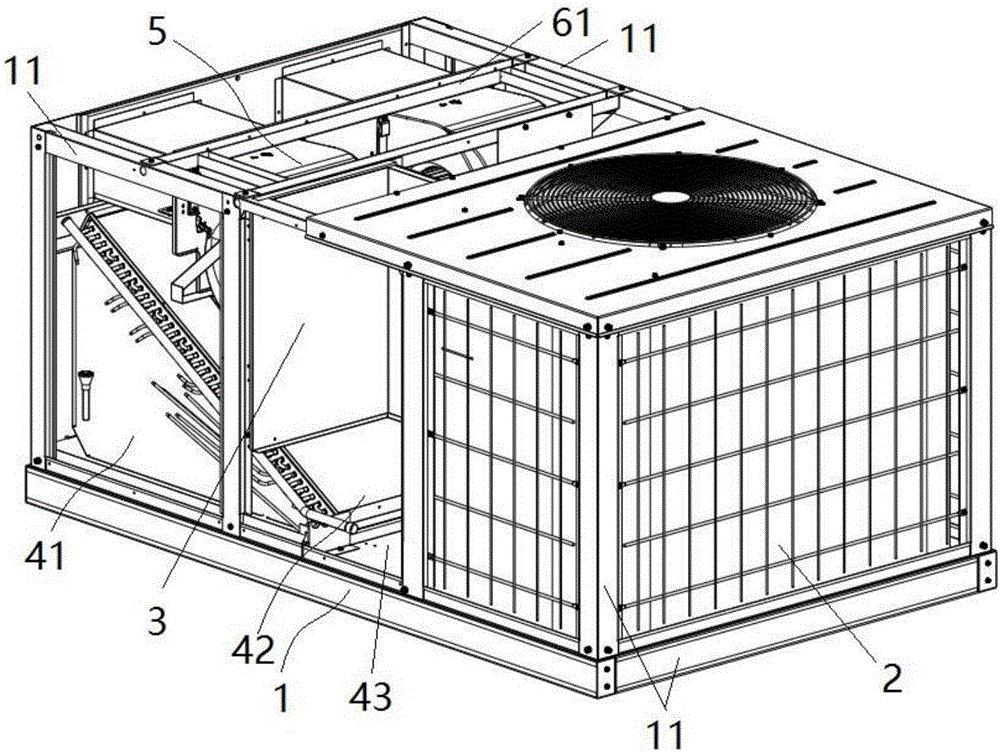

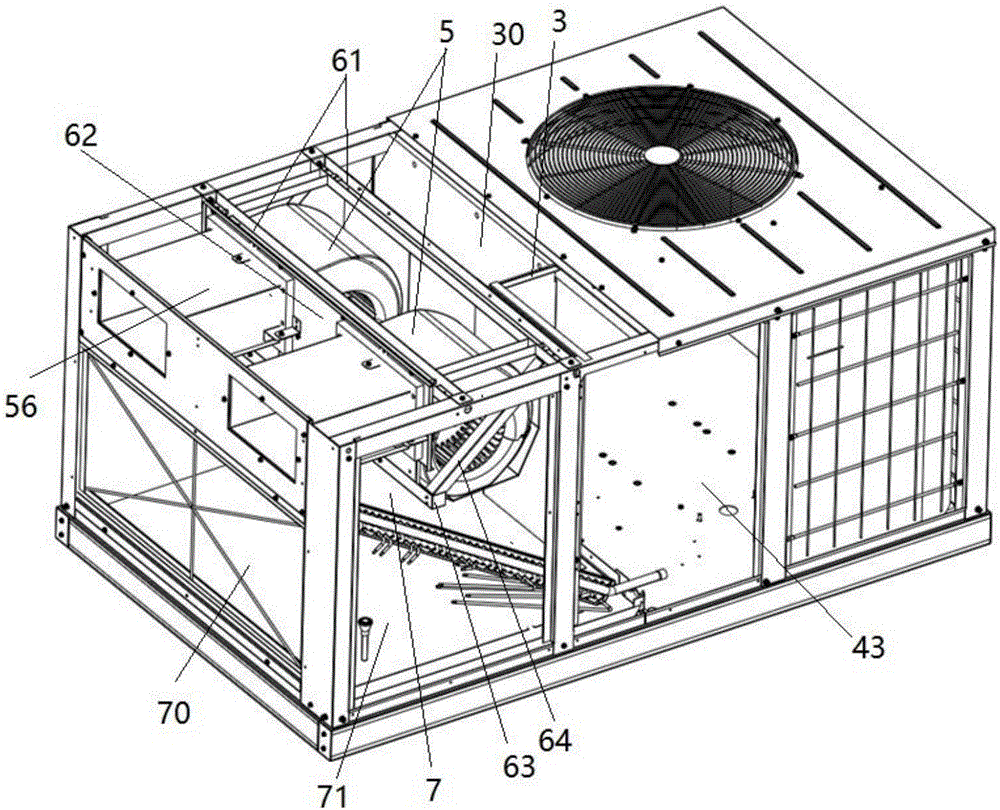

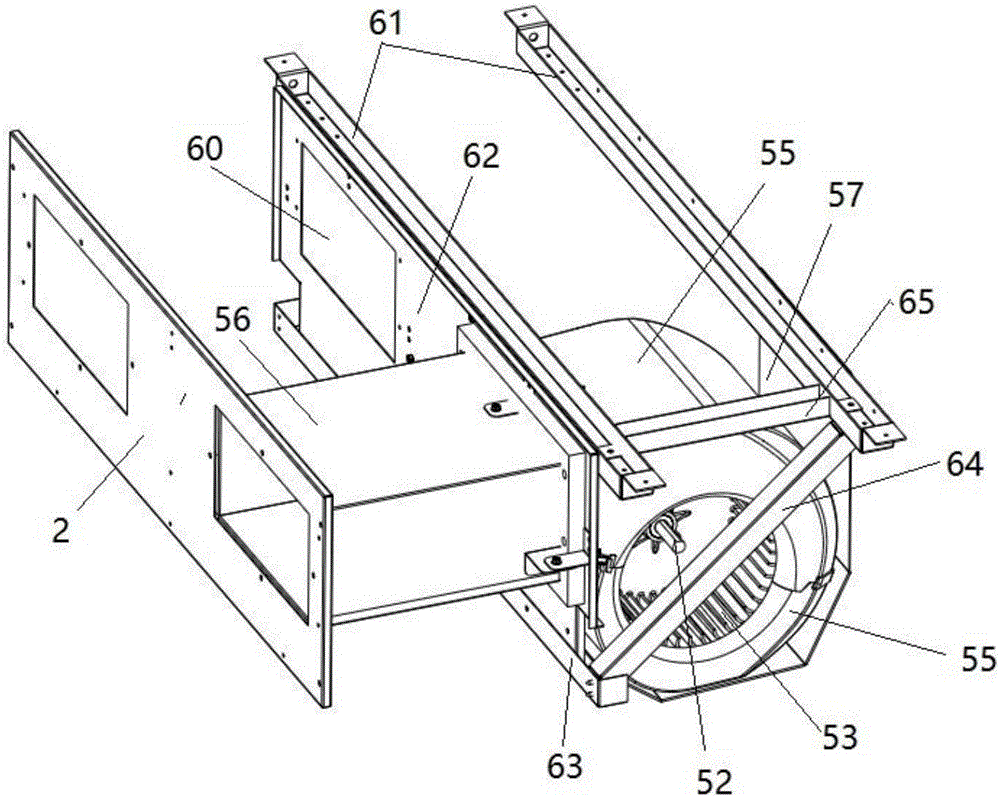

[0061] This embodiment provides a roof machine, such as Figure 1-2 As shown, it includes: a frame 1, which is formed by connecting profiles 11, and the middle part forms an installation space; the compressor is installed on the chassis 43 of the frame 1, and the fan 5 is located in the installation space and fixed on it by the installation structure. The frame 1 top.

[0062] In the rooftop machine of this embodiment, when the compressor and the fan 5 work at the same time, the vibration of one side is gradually transmitted to the position of the other side through the frame 1 connected by a plurality of profiles 11 through the connection structure, and the vibration has been greatly attenuated, which is not enough Strong resonance is caused. According to the actual test, the resonance phenomenon of the roof machine in this embodiment is not obvious, and there is no large noise due to resonance, and there is no phenomenon of equipment damage due to resonance. The location of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com