Heat pump unit adjusting method and device and air conditioner

A technology of a heat pump unit and an adjustment method, applied in the control field, can solve the problems of low reliability, many times of shutdown protection of the heat pump unit, shortening the service life of the unit, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

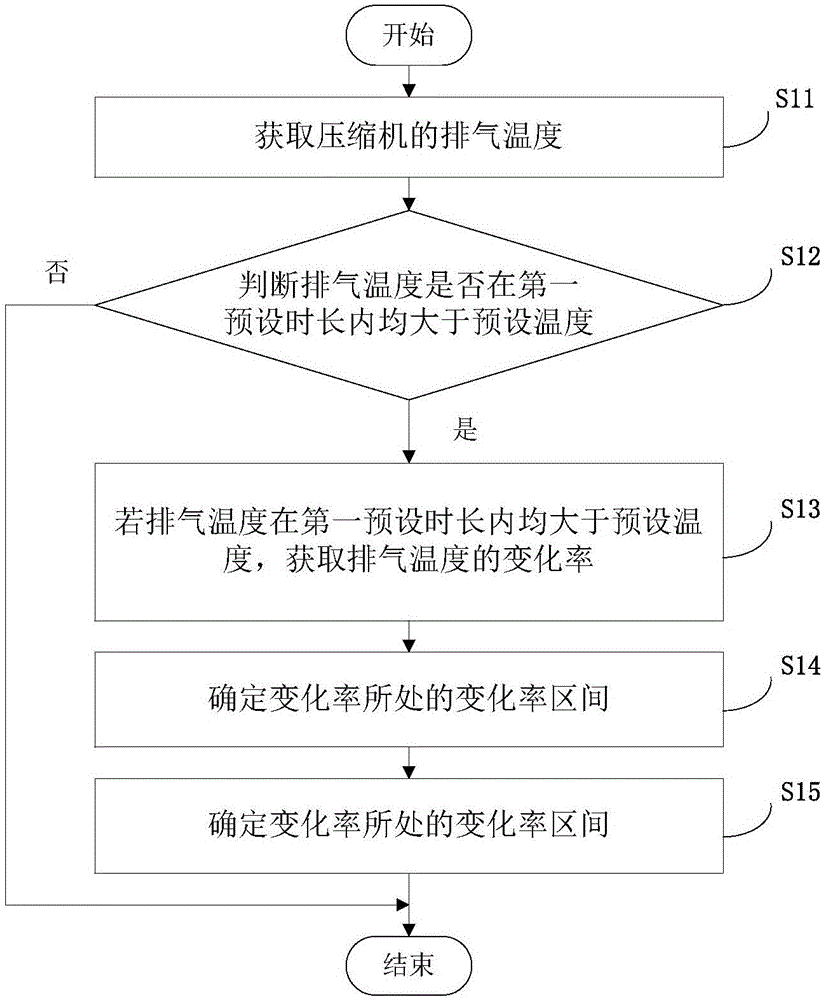

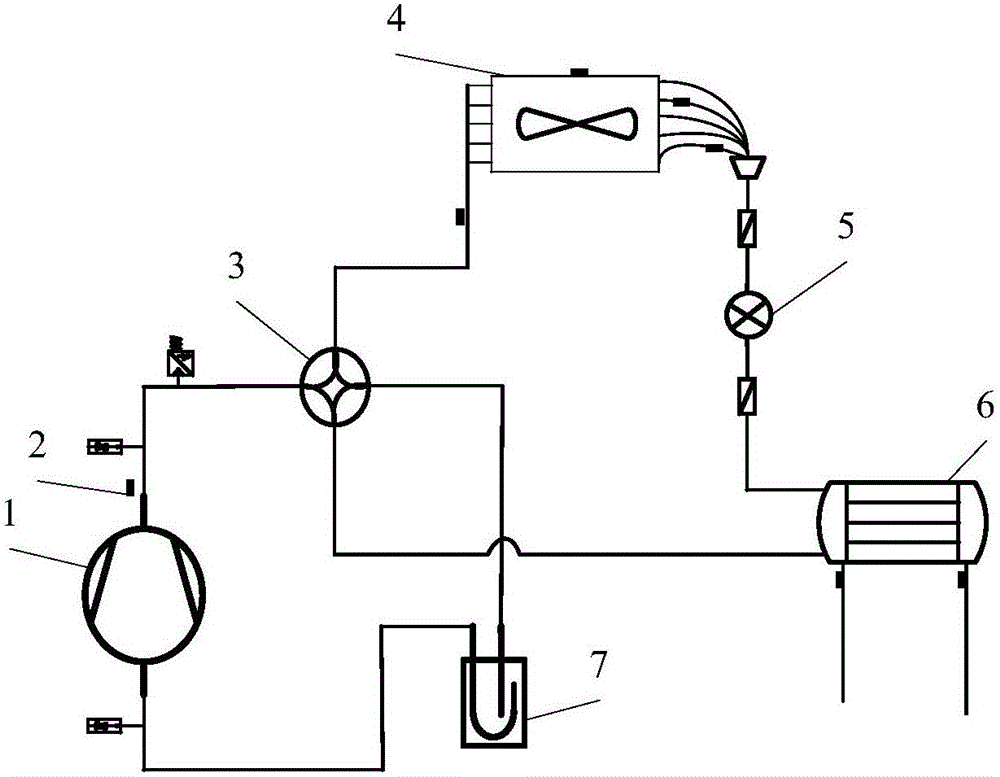

[0030] This embodiment provides a method for adjusting the heat pump unit, which can be used for temperature adjustment of the heat pump unit in high temperature protection projects, as follows figure 2 The shown heat pump unit is taken as an example to describe the technical scheme of the embodiment in detail, such as figure 2 As shown, the heat pump unit includes: compressor 1, exhaust temperature sensor 2, four-way valve 3, heat exchanger 4, electronic expansion valve 5 (that is, heat exchanger valve), shell tube 6 and vapor-liquid separator 7 ,Such as figure 1 As shown, the adjustment method of the heat pump unit includes the following steps:

[0031] S11: Obtain the discharge temperature of compressor 1, such as figure 2 As shown, the exhaust gas temperature of the compressor 1 can be acquired in real time by installing an exhaust gas temperature sensing package 2 at the exhaust port of the compressor 1 .

[0032] S12: Determine whether the exhaust gas temperature i...

Embodiment 2

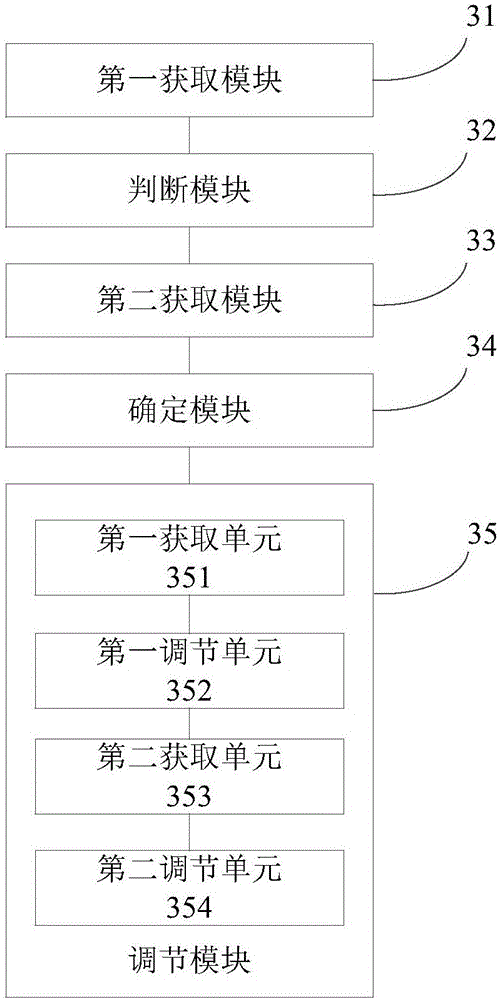

[0053] This embodiment provides a heat pump unit regulating device, which can be used to control the exhaust temperature of the heat pump unit, as follows: figure 2 The shown heat pump unit is taken as an example to describe the technical scheme of the embodiment in detail, such as figure 2 As shown, the heat pump unit includes: a compressor 1, an exhaust temperature sensor 2, a four-way valve 3, a heat exchanger 4, an electronic expansion valve 5, a shell tube 6 and a vapor-liquid separator 7, such as image 3 As shown, the heat pump regulating device includes a first acquisition module 31, a judgment module 32, a second acquisition module 33, a determination module 34 and an adjustment module 35. The functions of each module are as follows:

[0054] The first acquisition module 31 acquires the discharge temperature of the compressor 1 , for details, refer to the detailed description of step S11 in Embodiment 1.

[0055] The judging module 32 is configured to judge whether t...

Embodiment 3

[0065] This embodiment provides an air conditioner 40, which can be used to control the exhaust temperature of heat pump units, such as Figure 4 As shown, it includes the heat pump unit regulating device as in Embodiment 2, so it has all the beneficial effects of the heat pump unit regulating device in Embodiment 2.

[0066] The air conditioner 40 provided by the present embodiment, as figure 2 Taking the heat pump unit shown as an example, when the discharge temperature of compressor 1 is greater than the preset temperature for the first preset time, the rate of change of the discharge temperature of compressor 1 is detected in real time, and the rate of change is determined according to the range of the rate of change. Adjust the opening of the heat exchanger 4 valve in time. If the change rate of the exhaust gas temperature is still in the same range of change rate after the second preset time period, adjust the valve opening of the heat exchanger 4 and cooperate with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com