Novel high-frequency furnace and infrared carbon and sulfur analyzer

A technology of infrared carbon and sulfur analysis and high-frequency furnace, which is applied in the direction of furnace, furnace type, furnace components, etc., can solve the problems of discrepancy between the weight of the sample weighed and the weight of the heated sample, analysis result error, time waste, etc., to avoid The effect of sample partial omission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

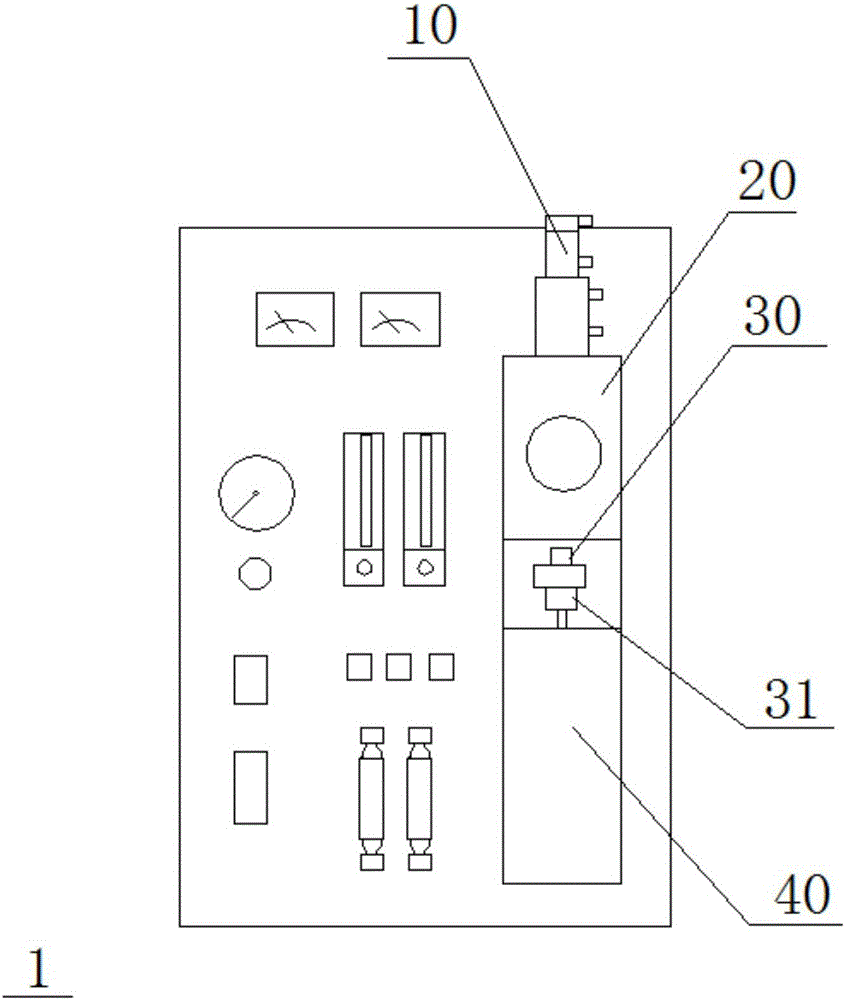

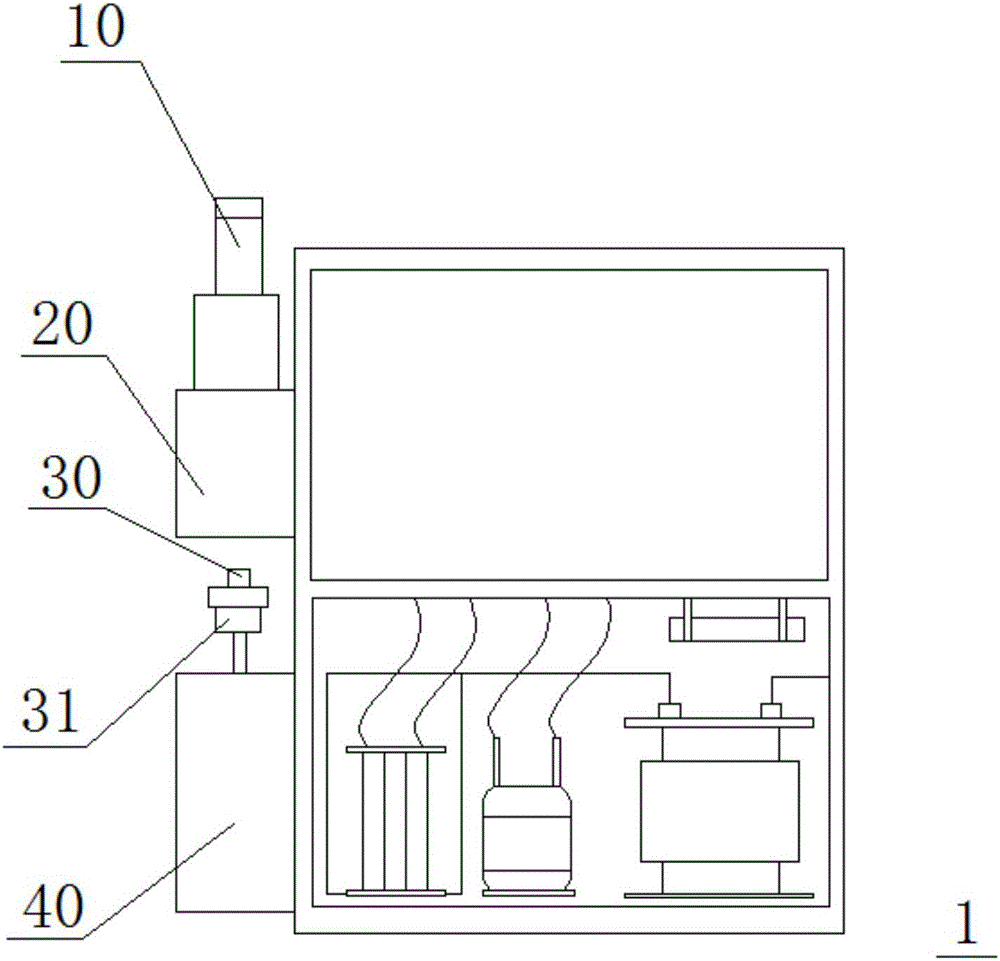

[0028] Such as figure 1 with figure 2 As shown, the novel high-frequency furnace 1 provided by the present invention includes a furnace head 10 and a combustion chamber 20, and the novel high-frequency furnace 1 is also provided with a crucible 30 and a crucible support 31; the crucible support 31 is provided with a weight Measuring unit, the weight measuring unit is used to measure the weight of the sample placed in the crucible 30 . Compared with the existing high-frequency furnace, the novel high-frequency furnace 1 provided by the present invention can directly weigh the sample to be tested through the weight measuring unit arranged on the crucible support 31, and then send the crucible 30 into the combustion chamber 20 for Heating reduces the operator’s steps of transferring the sample to the crucible 30 after the electronic balance weighs it, and avoids partial omission of the sample caused in the process of transferring the sample, resulting in a discrepancy between t...

Embodiment 2

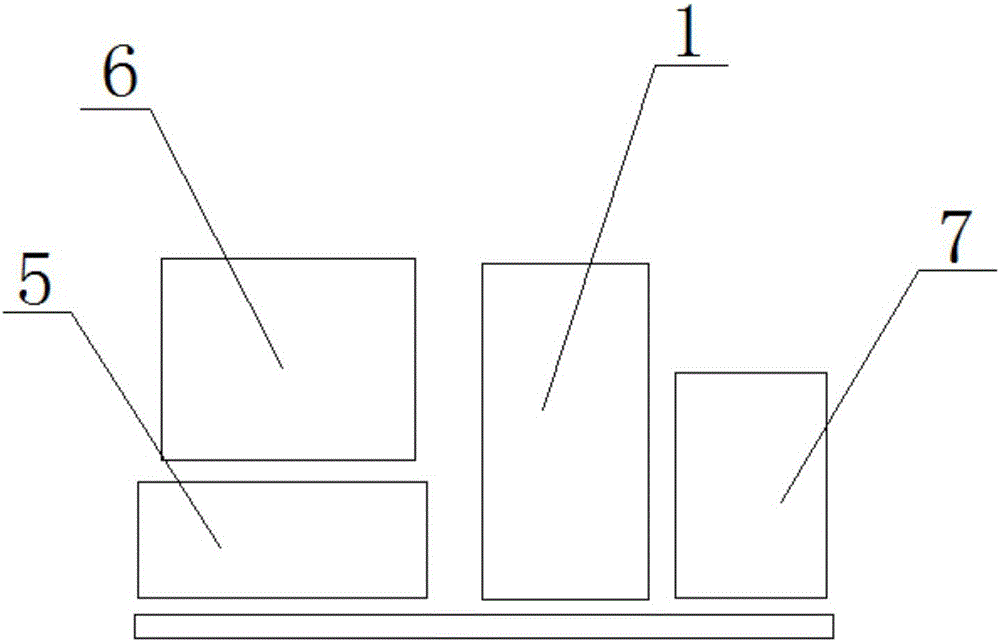

[0039] Such as Figure 4 As shown, the novel high-frequency furnace 1 provided by the present invention includes a furnace head 10 and a combustion chamber 20, and the novel high-frequency furnace 1 is also provided with a crucible 30 and a crucible support 31; the crucible 30 support is provided with a weight Measuring unit, the weight measuring unit is used to measure the weight of the sample placed in the crucible 30 . Compared with the existing high-frequency furnace, the novel high-frequency furnace 1 provided by the present invention can directly weigh the sample to be tested through the weight measuring unit arranged on the crucible support 31, and then send the crucible 30 into the combustion chamber 20 for Heating reduces the operator’s steps of transferring the sample to the crucible 30 after the electronic balance weighs it, and avoids partial omission of the sample caused in the process of transferring the sample, resulting in a discrepancy between the weighed samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com