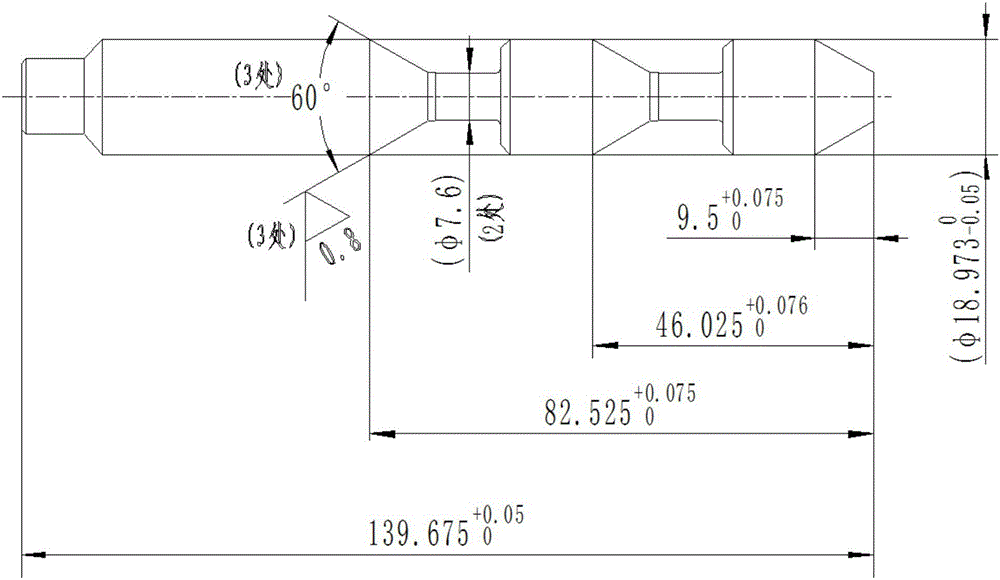

Tooling and method for detecting intersection point dimension of axial cone of interlock shaft

A technology of interlocking shafts and conical surfaces, which is applied in the detection field, can solve problems such as long detection cycle, affecting processing accuracy, and uneven surface of the inclined surface, so as to simplify the detection difficulty and avoid tedious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0017] Due to the structural characteristics of the interlocking shaft parts and the hardness of the heat-treated surface, vibrations are likely to occur during the machining of the inclined surface, resulting in uneven and asymmetric surfaces of the three axial sections of the inclined surface, which affect the machining accuracy such as linear dimensions and surface runout tolerances. However, at present, it is only possible to use a three-coordinate testing instrument or a projector to randomly select points on the slope to generate a virtual straight line and the outer circle to generate intersection points for measurement, resulting in a large difference in the size of the intersection between the three sections of the inclined plane and the outer circle; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com