Measuring method of length of convolution region of air vent of COREX fusion gasification furnace

A melting gasifier and measurement method technology, applied in the non-blast furnace ironmaking field, can solve the problems of less equipment for blast furnace production and expensive equipment, and achieve the effects of easy implementation, convenient operation, and simple measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0037] The measuring method of a kind of COREX melter-gasifier tuyere swirl length of the present invention comprises the following steps:

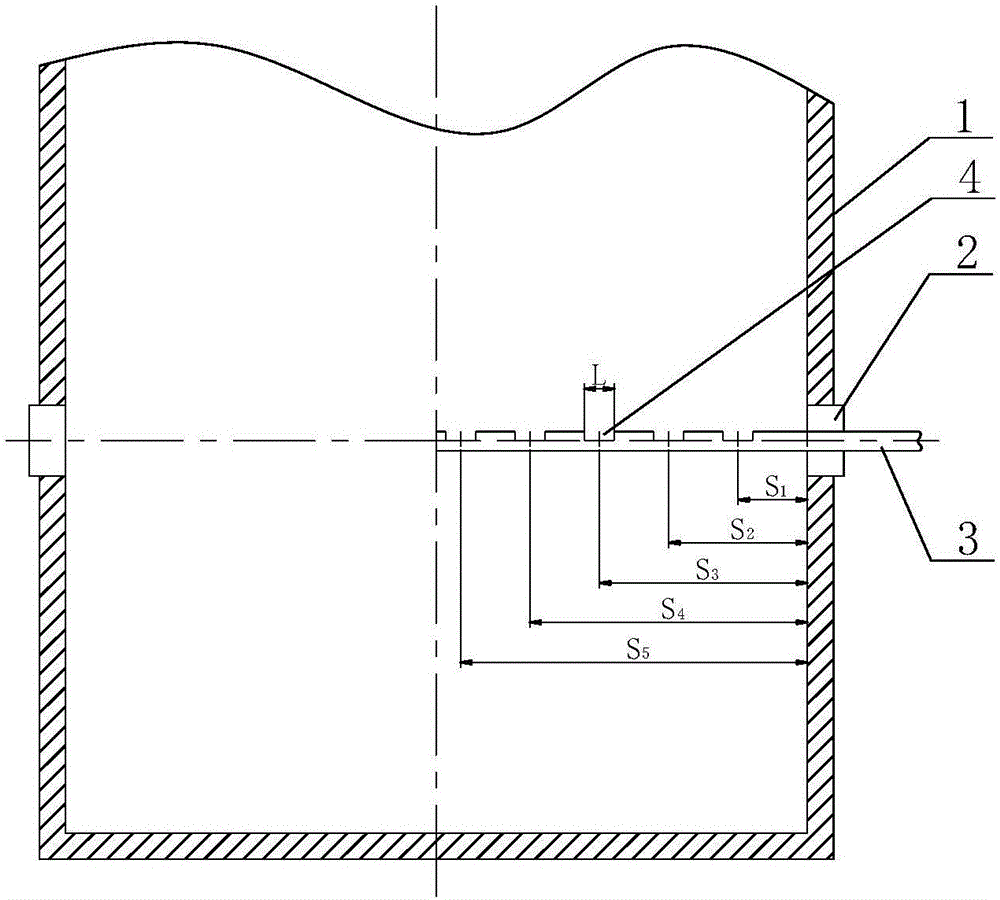

[0038] 1) Sampling; if figure 1 As shown, on the central plane of the tuyere 2 of the COREX melter-gasifier, along the radial direction of the COREX melter-gasifier 1, the coke samples of the tuyere are taken from different positions from the tuyere 2 to the center of the COREX melter-gasifier 1 through the tuyere sampler 3 , and number the obtained tuyere coke samples;

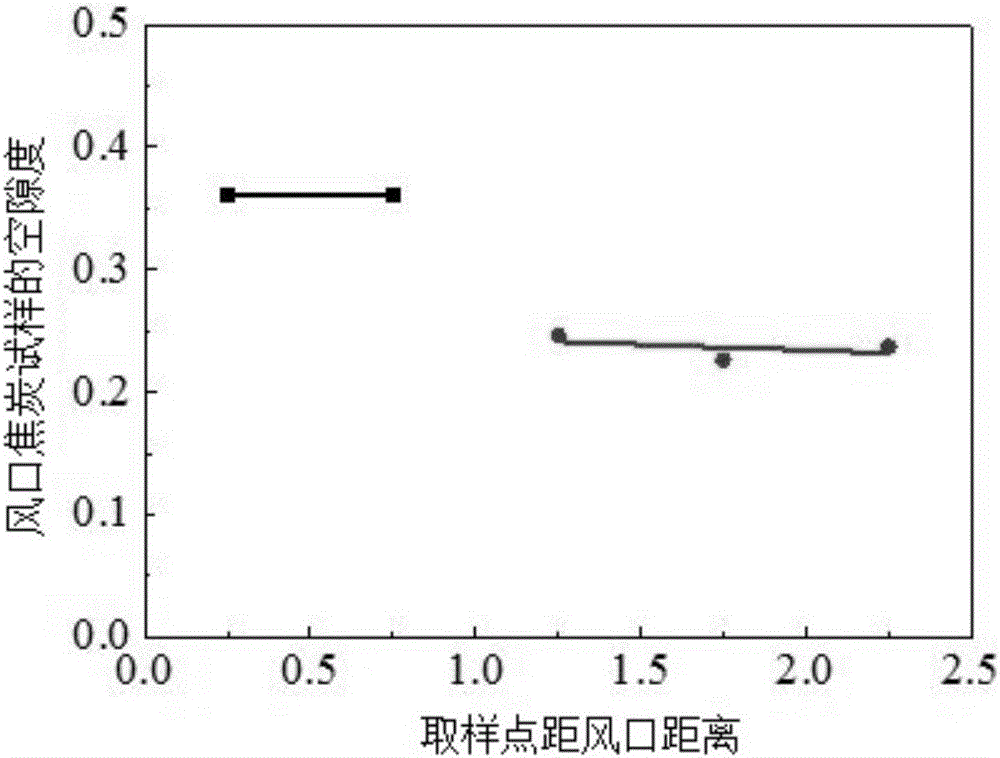

[0039] 2) Calculate the porosity of the tuyere coke samples at different positions, the porosity of the tuyere coke samples refers to the porosity of all particle sizes;

[0040] 3) Take the distance from the sampling point to the tuyere as the abscissa, and take the porosity of the tuyere coke sample as the ordinate to draw a coordinate d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com