Measurement system, measurement method, evaluation method and compensation method for depth camera error

A technology of depth camera and error measurement, which is applied in the field of optical measurement, can solve the problems of depth camera error measurement and evaluation, and achieve the effect of accurate measurement and evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

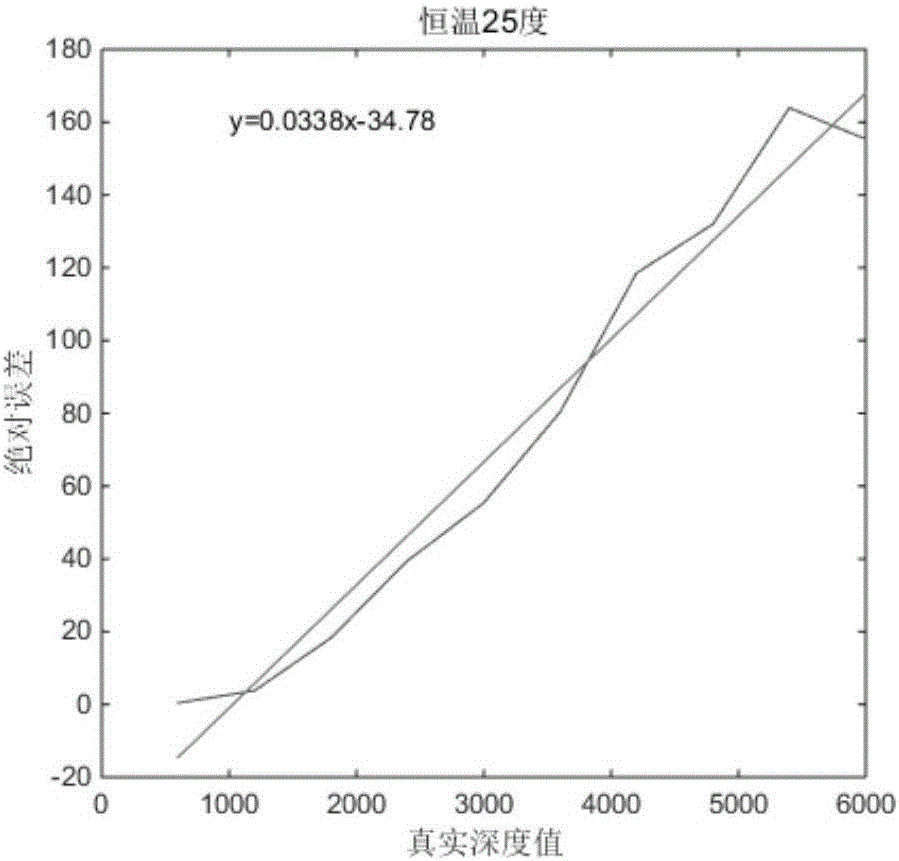

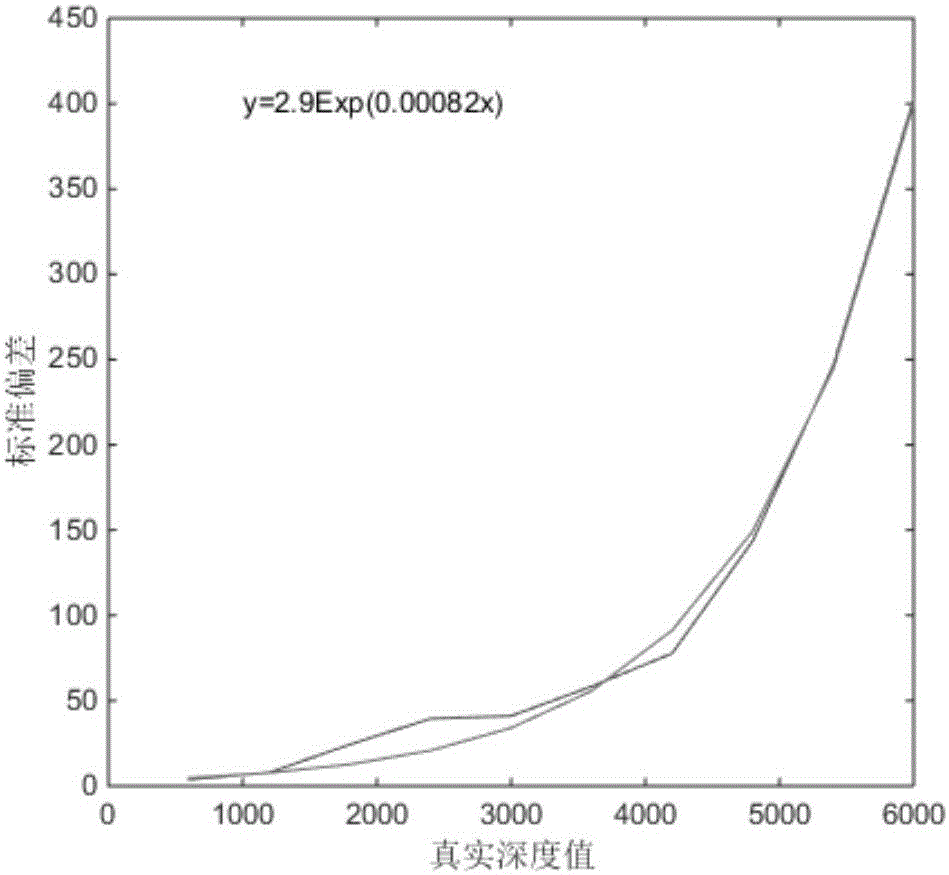

[0039] The depth measurement accuracy of the depth camera is mainly measured by two indicators: error and deviation. The error is used to measure the accuracy of the depth camera, and the standard deviation is used to measure the precision of the depth camera. Other precision representation methods may also be used in other embodiments.

[0040] (1) Error measurement method

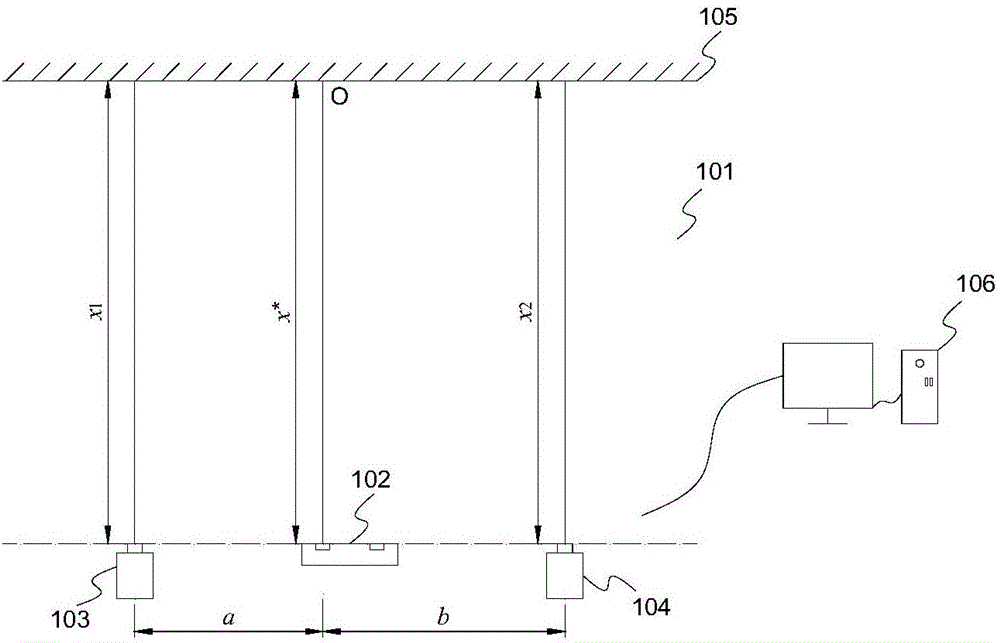

[0041] Error e(x * ) is represented by the difference between the measured value x* and the true value x, namely: e(x*)=x−x*. The acquisition of the true value is obtained by using a measuring device with higher precision, such as a laser range finder. When measuring, aim the depth camera at a plane, and place laser rangefinders on both sides of the depth camera, and the three are on the same baseline, such as figure 1 shown. In the actual measurement, the depth camera and the laser range finder are fixed on a movable base for synchronous movement.

[0042] The true value can also be obtained in othe...

Embodiment 2

[0050] Such as figure 1 Shown is a schematic diagram of a measurement system according to an embodiment of the present invention. The error measurement system 101 includes a depth camera 102 , laser range finders 103 and 104 , a measurement plane 105 and a computer 106 . The depth camera can be a depth camera based on structured light, TOF or binocular vision principles. Generally, the measurement accuracy (error) of the depth camera does not exceed 1% of its measurement distance, so the selected laser rangefinder is required to have a measurement accuracy higher than 1%, preferably at least an order of magnitude higher, that is, 0.1% , so that the data measured by the laser range finder is convincing when it is used as the real value.

[0051] Such as Figure 4As shown, when calculating the error in theory, it is necessary to measure the measured value and the real value of the same point or several points by the depth camera and the laser range finder. However, since the...

Embodiment 3

[0054] In this embodiment, the depth measurement error caused by the change of the measurement distance is mainly explained, and an evaluation method is given. Measurement distance variation is the biggest cause of error in depth cameras during normal use. Generally speaking, the measurement error increases with the increase of the measurement distance. In order to quantitatively evaluate the error change, in this embodiment, the measurement error of the depth camera at different measurement distances will be measured and quantitatively analyzed in combination with the above-mentioned error measurement system and measurement method.

[0055] In one embodiment, the measurement range of the depth camera 102 is 0.6-6m, and an error measurement is performed on the depth camera every 0.6m. In order to eliminate the influence of temperature, a temperature controller such as a semiconductor cooler (TEC) can be used to control the depth camera at a constant temperature.

[0056] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com