Automatic agent coating device for glass slide

A technology of glass slides and reagents, applied in the field of medical supplies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

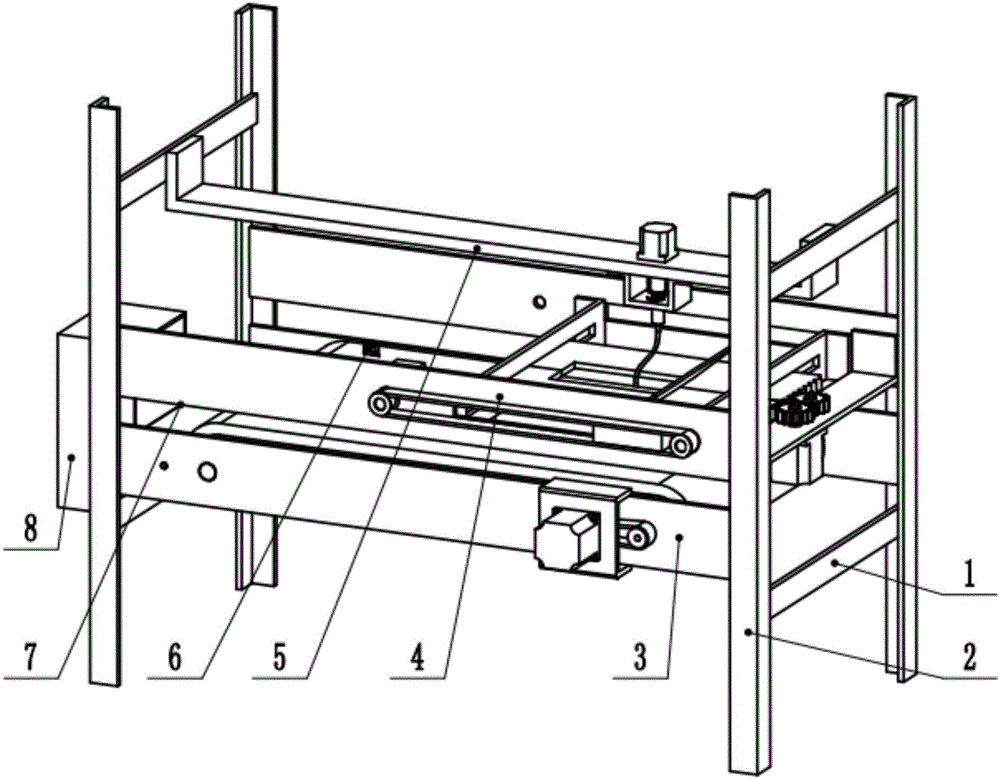

[0013] An automatic application device for slide reagents is composed of a horizontal support 1, a vertical support 2, a conveyor belt module 3, a smearing module 4, a reagent supply module 5, a fan 6, a slide transfer plate 7 and a slide collection box 8. The structure is characterized in that: the structure of the vertical support 2 is a V-shaped plate, including four vertical supports 2 located at the four corners of the whole device, and the horizontal support 1 is installed at the lower part of the vertical support 2. The number of the horizontal bracket 1 is two, the conveyor belt module 3 is installed below the vertical bracket 2 and above the horizontal bracket 1, and the smear module 4 is installed on the vertical bracket 2 and above the conveyor belt module 3. The supply module 5 is installed above the vertical support 2 and above the smearing module 4, the fan 6 is installed on the smearing module 4, the slide transfer board 7 is installed on the conveyor belt module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com