Inclined percussion experiment method and slope percussion device of powdery energetic material

A test method and impact device technology, which is applied in the direction of measuring devices, analyzing materials, adopting mechanical devices, etc., can solve problems such as the evaluation of the safety of non-energetic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

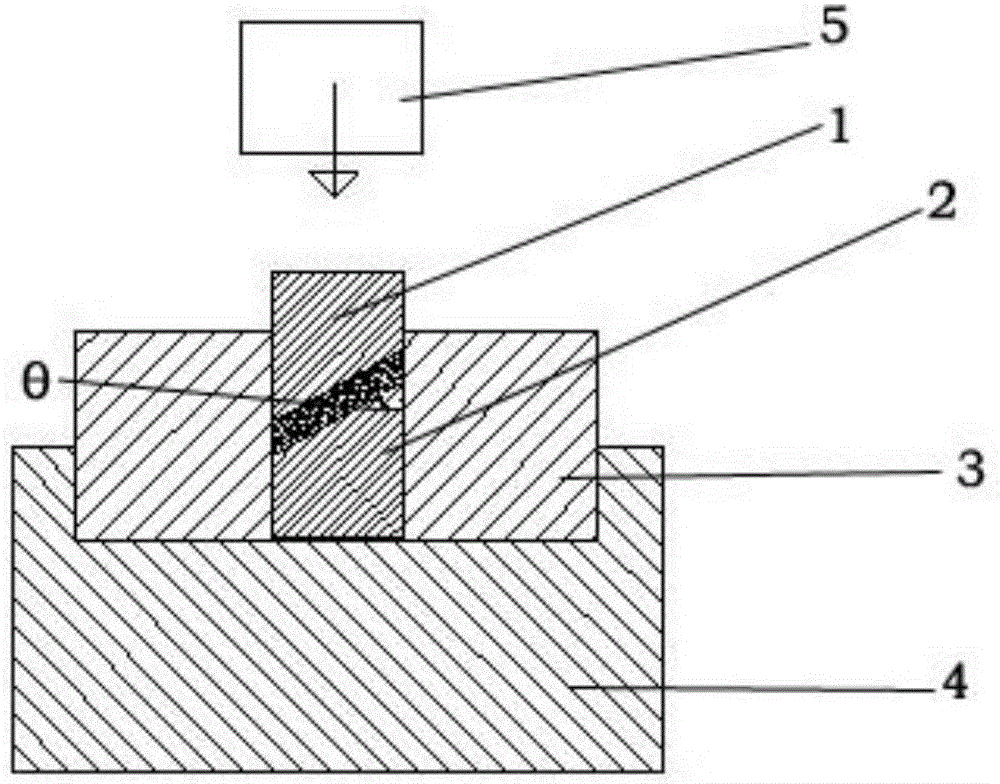

[0028] a kind of like image 3 The shown oblique impact device for implementing the oblique impact test method of the above-mentioned powdery energetic material includes a drop weight 5, a strike sleeve 3, a base 4 and an oblique impact column (1, 2); directly above the column; the impact sleeve is fixed on the base, and the oblique impact column is matched and installed in the impact sleeve. The oblique impact column is divided into an upward oblique impact column 1 and a downward oblique impact column 2. Explosive powder is installed between the column and the downward inclined impact column, and the bottom surface of the upward inclined impact column and the top surface of the downward inclined impact column are slopes with the same slope angle.

[0029] In a specific embodiment of the present invention, the overall shape of the oblique impact column is cylindrical or square.

Embodiment approach

[0030] Another specific embodiment of the present invention, the diameter of the oblique impact column is 10cm.

[0031] The bottom surface of the upward slanting impact column and the top surface of the downward slant impact column are both slopes with an angle θ of 60° or 45°. If the emphasis is on impact, choose a stud with a larger bevel angle; if you focus on friction, choose a stud with a smaller bevel angle.

[0032] In a further technical solution of the present invention, the drop hammer is arranged 25 cm directly above the oblique impact column, and the weight of the drop hammer is 10 kg.

[0033] The application of the above inclined plane impact device in the oblique impact test of powdery energetic materials is as follows:

[0034] When conducting oblique impact tests of powdery energetic materials, the inclined plane impact device was first cleaned with acetone and dried for later use; then the explosive test samples were dried, and the dried explosive test samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com