Edible oil quality testing method, equipment and system

一种品质检测、食用油的技术,应用在材料激发分析、荧光/磷光等方向,能够解决无法实现现场实时检测、使用、无法鉴别出食用油品质等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

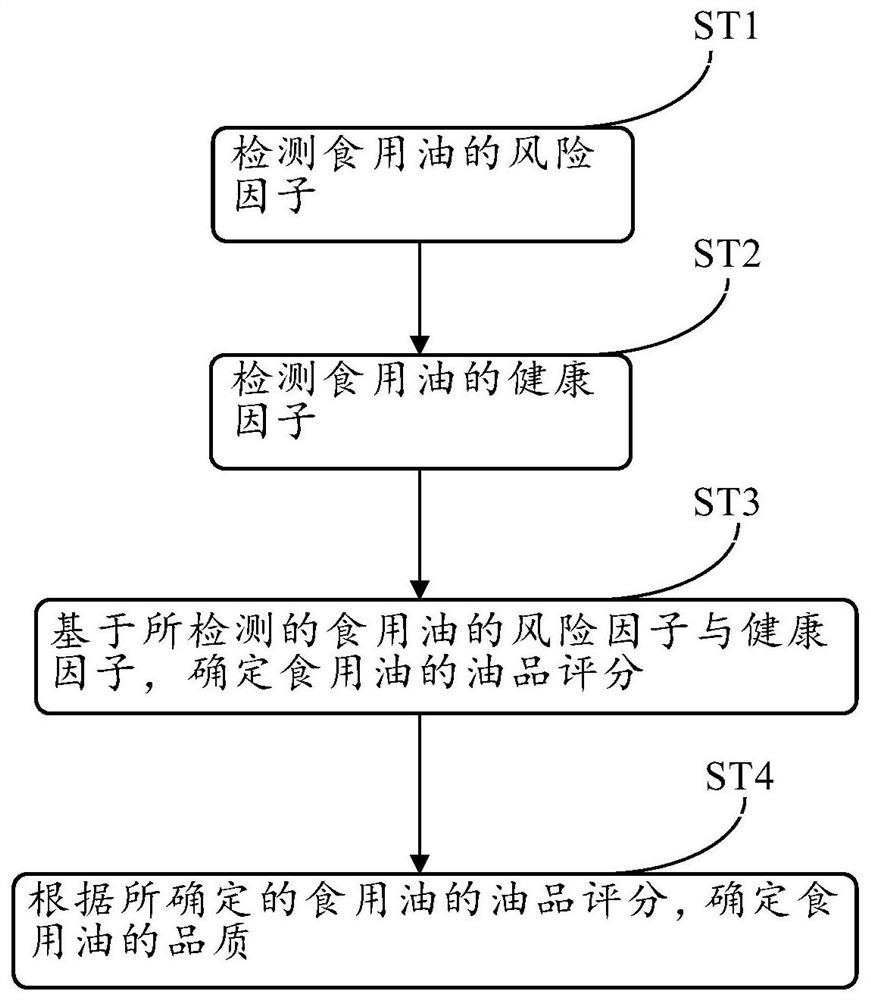

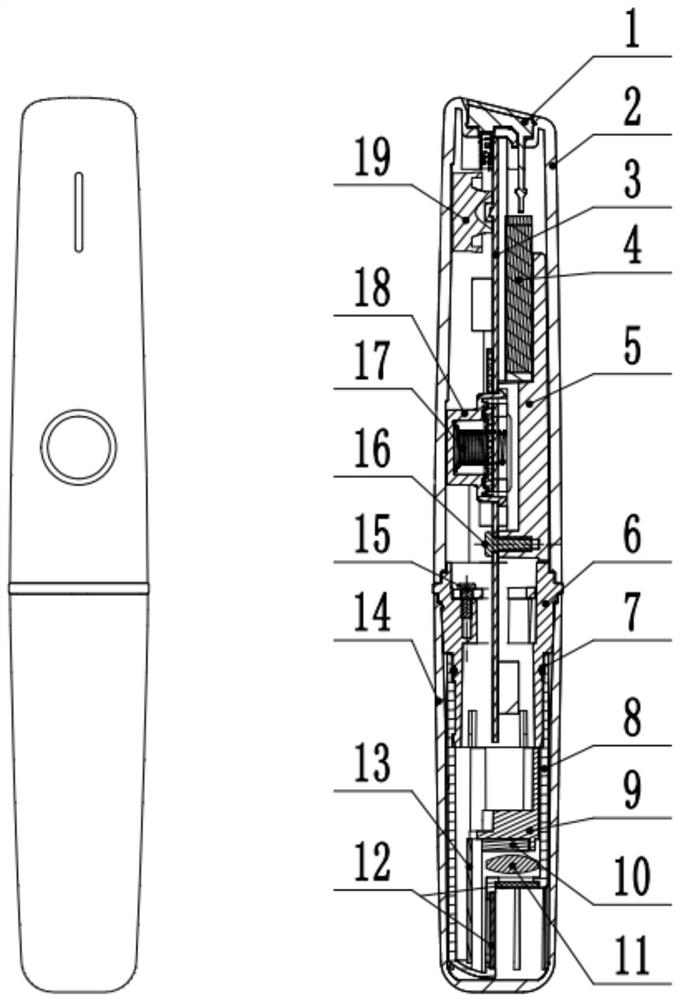

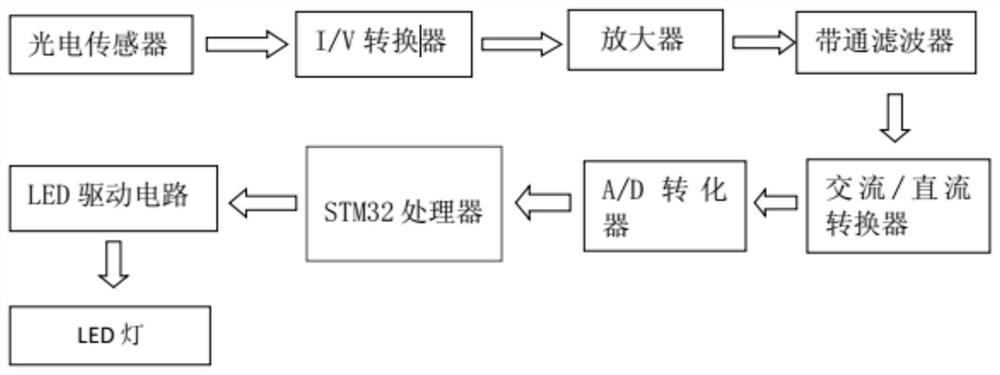

[0017] In the present invention, according to the principle that edible oil will produce fluorescence under the excitation of excitation light of specific wavelength, the edible oil is excited with light of specific wavelength, and the fluorescence signal emitted by the edible oil under the excitation of light of specific wavelength is collected. Afterwards, a digital signal representing the intensity of the above-mentioned fluorescent signal is obtained. For example, through a series of transformations, the peak area of the aforementioned fluorescence signal (that is, the area covered by the part whose value on the vertical axis is greater than the baseline) in the fluorescence spectrogram curve (the horizontal axis is the wavele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com