Multi-layer Rock-soil layer heat conductivity coefficient testing method

A technology of thermal conductivity and testing method, which is applied in the field of layered thermal conductivity testing of rock and soil layers, can solve problems such as changes in the length of buried pipes and the total length of boreholes, and achieve the effect of ensuring long-term high-efficiency operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

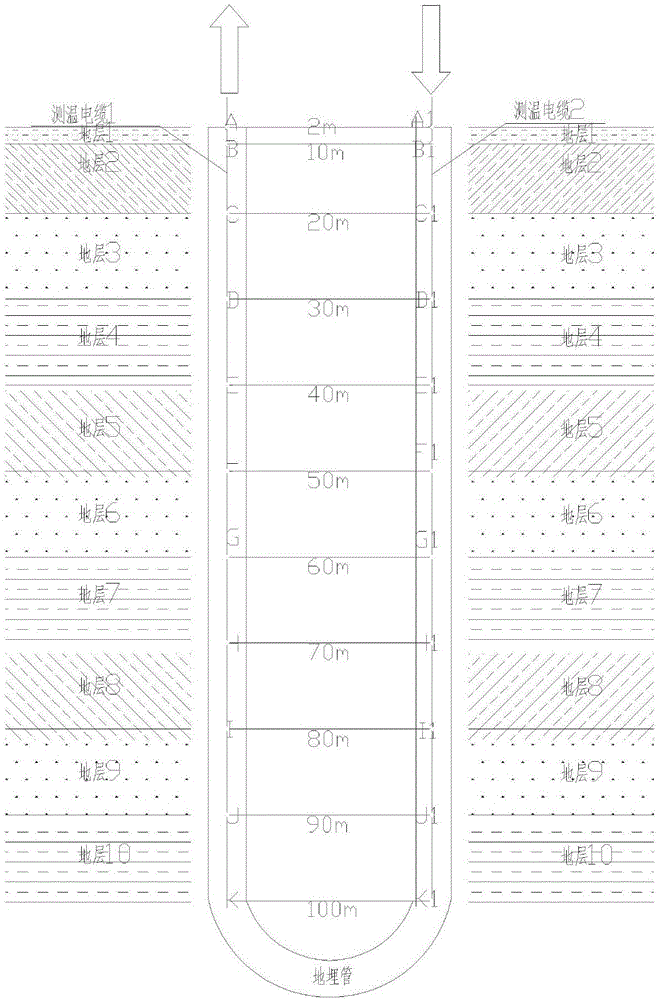

[0035] Such as figure 1 As shown in the figure, the drilling rig is used to drill holes, and temperature measuring cables are installed in the inlet and outlet pipes of the U-shaped underground pipes.

[0036] The length of the temperature measurement cable is 100m, and a total of 11 temperature sensors are arranged at the 2m, 10m, 20m, 30m, 40m, 50m, 60m, 70m, 80m, 90m, and 100m. The corresponding temperature measurement cables 1 are A, B, C, There are 11 probes in D, E, F, G, H, I, J, and k, and the same temperature measurement cable 2 is A1, B1, C1, D1, E1, F1, G1, H1, I1, J1, and k1. The probe divides the formation into 10 formations of 2-10m, 10-20m, 20-30m, 30-40m, 40-50m, 50-60m, 60-70m, 70-80m, 80-90m, and 90-100m.

[0037] The buried pipe enters the water from the right side and flows out from the left side after exchanging heat with the soil, and then flows to the water inlet on the right side. This repeated cycle of heat exchange with the soil finally achieves the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com