Glass coating wire detector

A technology of glass coating and testing instruments, applied in the direction of material magnetic variables, etc., can solve the problems of high production costs, achieve the effects of simplifying analog circuits, reducing signal-to-noise ratio, and ensuring robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

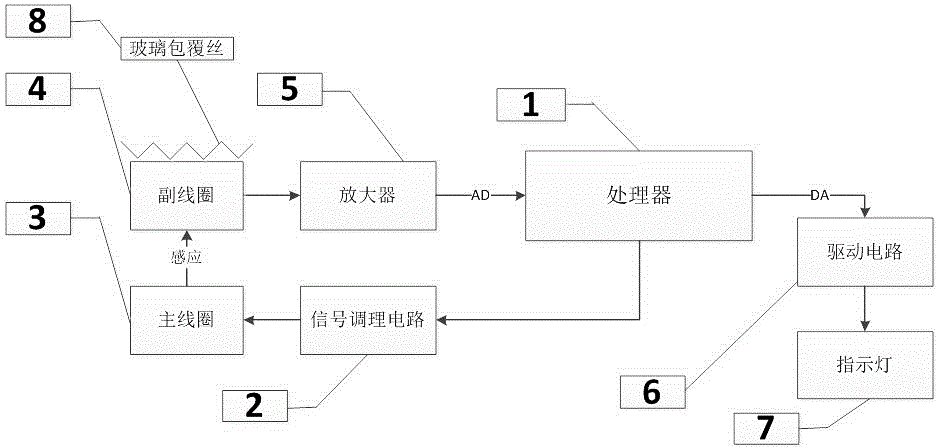

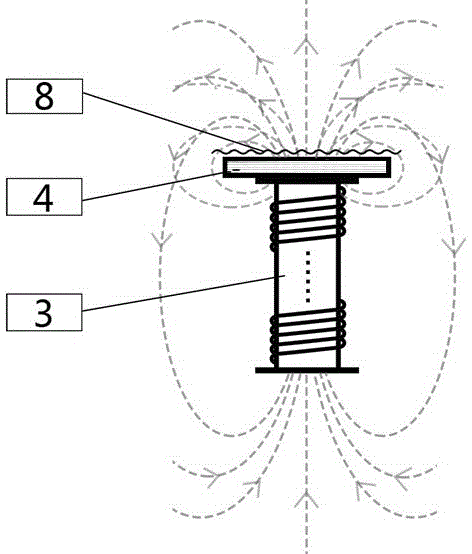

[0017] Such as figure 1 As shown, the glass-coated wire detection instrument of the present invention includes: a processor system 1 , a signal integration circuit 2 , a main coil 3 , a secondary coil 4 , an amplifier 5 , a drive circuit 6 , and an indicator light 7 . There is only one primary and secondary coil respectively.

[0018] In this embodiment, the processor MCU (1) adopts a 32-bit Cortex-M3 processor with an instruction execution capability of 150DMIPS and an AD converter with a rate of 6Msps. Processor MCU (1) generates a sinusoidal signal with fixed frequency (200HZ) and fixed amplitude (2.5V). The function of this signal is to allow the disturbance effect of the glass-coated wire on the magnetic field to be intuitively reflected through this sinusoidal carrier.

[0019] The sinusoidal signal is transformed into a ladder-type analog signal through DA con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com