High-pressure double-membrane water treatment device

A water treatment device and double-membrane technology, applied in water/sewage treatment, reduced water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as high equipment cost, low work efficiency, and large floor space , to achieve the effect of reducing floor area and cost, improving efficiency and ensuring water production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

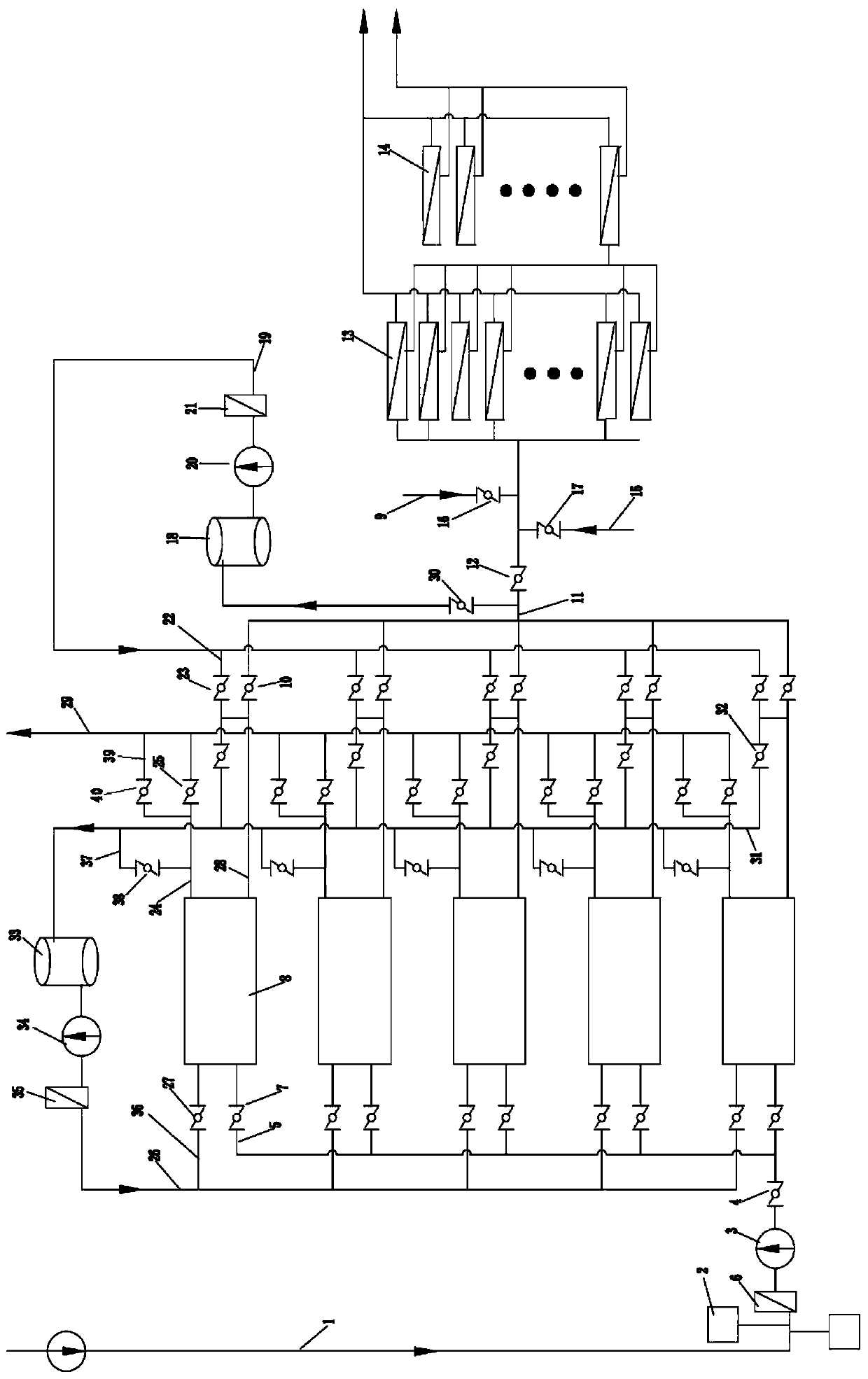

[0012] Attached below figure 1 To further explain the present invention:

[0013] A high-pressure double-membrane water treatment device. A dosing device 2 is connected to the water inlet pipe 1. The water inlet pipe 1 is provided with a filter a6, a high-pressure pump 3 and a control valve a4. The water inlet pipe 1 is connected to several inlets. Water branch 5, each inlet branch 5 is provided with a control valve b7 and a high-pressure ultrafiltration membrane group 8. The outlet pipe b28 of the high-pressure ultrafiltration membrane group 8 is connected to the outlet main pipe a11 through the control valve c10, and the outlet main pipe a11 is provided There is a control valve d12, the outlet header a11 is connected to the reverse osmosis membrane group a13, the outlet pipe a24 of the high-pressure ultrafiltration membrane group 8 is connected to the outlet pipe c39, the outlet pipe c39 is connected to the outlet header b29, and the outlet pipe c39 is provided with a control v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com