Concentrating and recovering device for copolymerization resin waste water and recovery method thereof

A waste water concentration and recovery device technology, which is applied to chemical instruments and methods, permeation/dialysis water/sewage treatment, semi-permeable membrane separation, etc., can solve the problem that the mother liquor cannot be reused, the operation of waste liquid is not stable enough, and the waste water has not been reached. Clean production and other issues, to achieve the effect of reducing adhesion, small footprint, and reduced probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

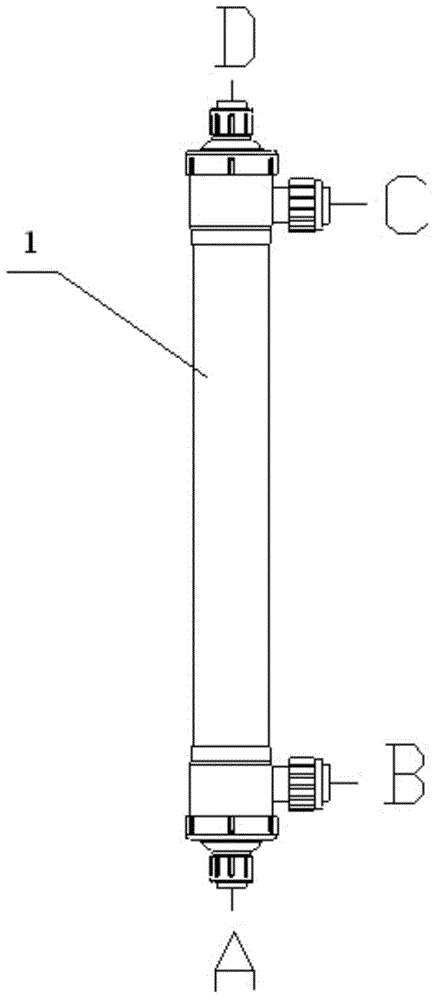

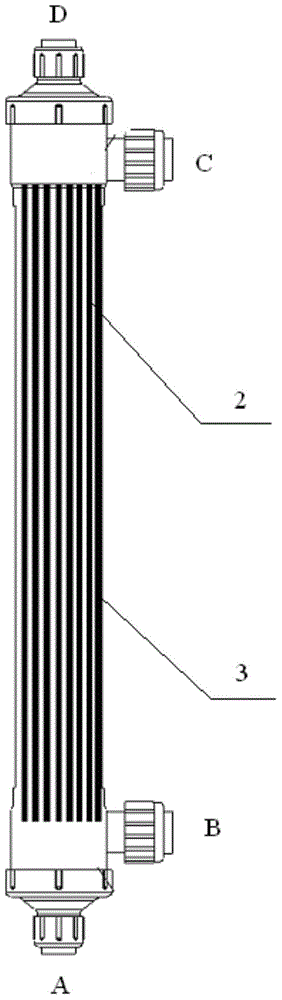

[0036] Such as Figure 1-2 As shown, the copolymer resin wastewater concentration and recovery device includes a membrane shell 1, and a permeation cavity 2 is arranged in the membrane shell 1, and a plurality of hollow tubular hollow fibers 3 are arranged in the permeation cavity;

[0037] The bottom end of the membrane shell 1 is provided with an A interface, the top end is provided with a D interface, the upper end of the side is provided with a C interface, and the lower end of the side is provided with a B interface.

[0038] The number of the hollow tubular hollow fibers 3 ranges from hundreds to tens of thousands, and the outer diameter thereof is 1-2 mm. The top end of the hollow tubular hollow fiber 3 is fixed on the permeation cavity, and the other end is blocked and not fixed. The hollow tubular hollow fiber can only pass through small molecular particles but not large molecular particles; the small molecular particles are substances with a molecular weight of thousa...

Embodiment 2

[0042] The method for reclaiming waste water by the copolymer resin waste water concentration recovery device, the steps are as follows:

[0043] (1) Operation: A port enters waste water with a flow rate of 100-300L / m 2 · h, pressure 0. 02-0. 15MPa; B port into the compressed air, the flow rate is 0.05-0.15Nm 3 / h, pressure 0. 1-0. 12MPa; C port is the concentrated water outlet; D port is the permeate outlet, the flow rate is 10-25L / m 2 h;

[0044] Backwashing: After running for 1 hour, the backwashing water enters the D port with a flow rate of 100-300L / m 2 h, pressure 0. 02-0. 15MPa; C port is the compressed air inlet, the flow rate is 0.05-0.15Nm 3 / h, pressure 0. 1-0. 12MPa; A port is the washing water outlet; backwash 60s;

[0045] Positive flushing: After backwashing, flushing water enters the A port with a flow rate of 100-300L / m 2 h, pressure 0. 02-0. 15MPa; B port is the compressed air inlet, the flow rate is 0.05-0.15Nm 3 / h, pressure 0. 1-0. 12MPa; C interf...

Embodiment 3

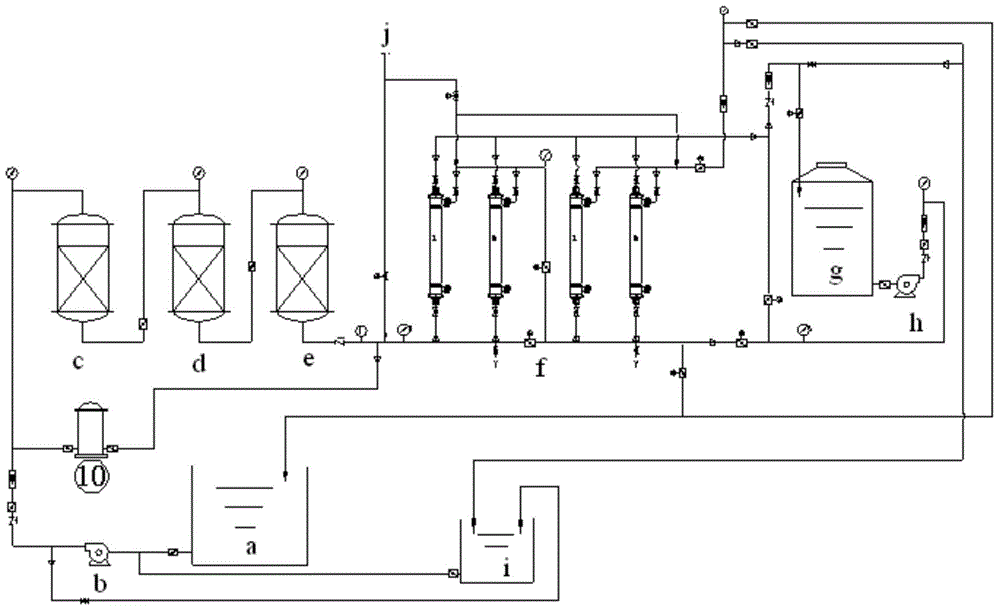

[0055] Embodiment 3 overall system technological process

[0056] Such as image 3 As shown, the wastewater to be treated is located in the raw material pool a, and the raw material pool a is connected to the raw material pump b, and the raw material pump b extracts the raw material wastewater from the raw material pool a, and passes through the first filter c, the second filter d and the third filter in sequence device e, and then enter a group of copolymer resin waste water concentration recovery device f, the copolymer resin waste water concentration recovery device f is connected with the permeate liquid pool g, and the permeate liquid pool g is connected with a backwash pump h, and the permeate liquid pool g is also connected with Medicine washing tank i connection;

[0057] The raw material pump b is also connected to the medicine washing filter j; the copolymer resin wastewater concentration and recovery device f is fed into the compressed air h.

[0058] When the who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com