Research and development of Co-based amorphous-wire steel-plate crack detector

A technology for crack detection and amorphous wire, which is applied in the direction of material magnetic variables, etc., can solve the problems that cannot meet the needs of actual production, the detection equipment is huge, and cannot be carried around, so that the detection process is convenient and flexible, and the accuracy and sensitivity are improved. Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objects and advantages of the present invention clearer, it will be described in detail below in conjunction with the accompanying drawings and specific implementation examples. The following examples are only used to allow others to better understand the present invention, and are not intended to limit the present invention.

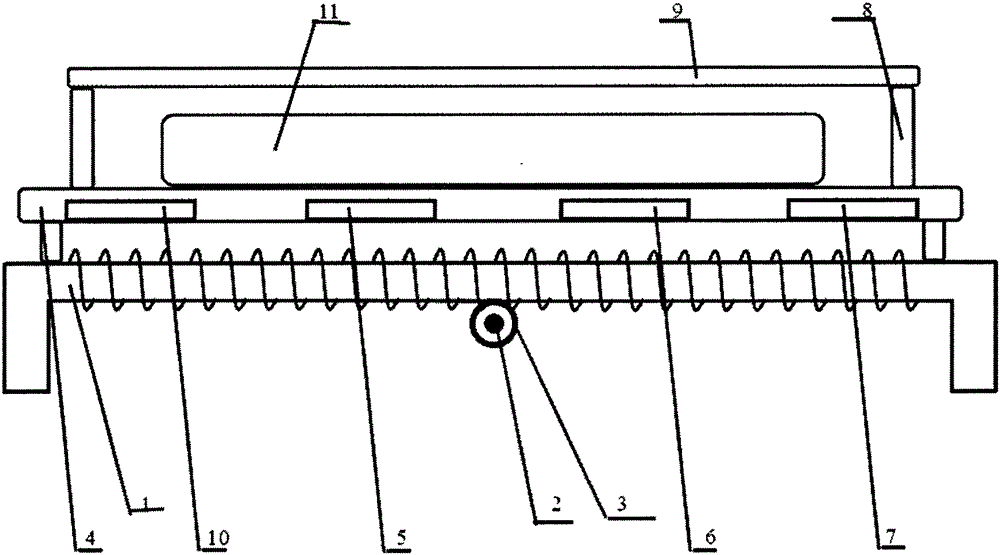

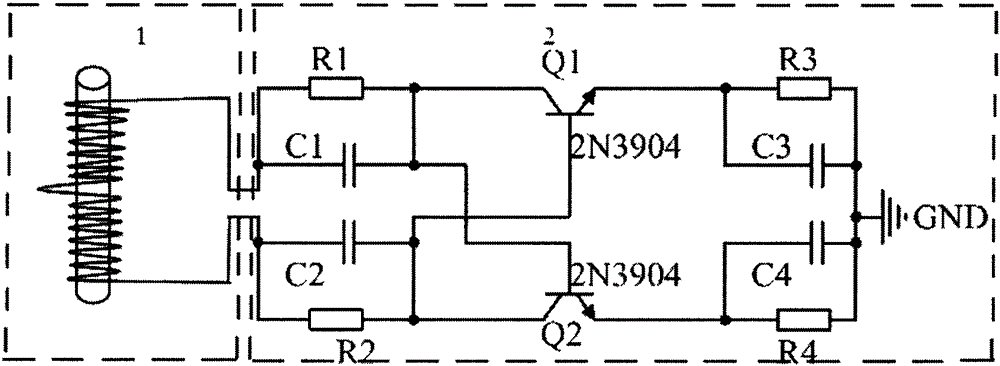

[0027] The overall structure of the steel plate crack detector is as follows: figure 1 shown. Including electromagnet (1), Co-based amorphous wire (2), double winding coil (3), main control circuit board (4), multivibrator circuit (5), signal amplification circuit (6), signal processing circuit (7 ), a touch display interface (8), a touch display (9), a power supply circuit (10), and a 12V lithium battery (11).

[0028] The composition of the electromagnet (1) in this tester: 3 layers of coils are wound on the iron core, and each layer contains 300 pieces of enamelled copper wire with a diameter of 0.15mm to form an electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com