Dynamic testing device for isolation ability of cementing sheath and experimental method

A technology for dynamic testing and cementing cement, applied in the field of cementing in petroleum engineering, can solve problems such as single testing method, and achieve the effect of improving experimental accuracy and enriching monitoring methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with drawings and embodiments.

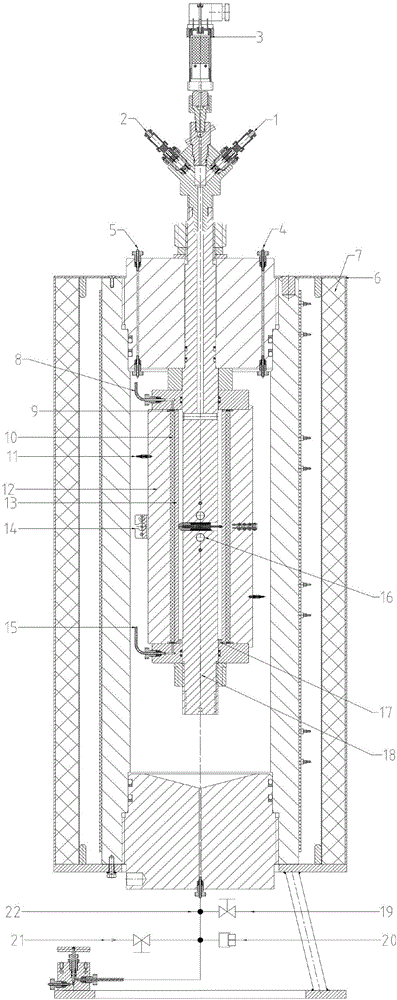

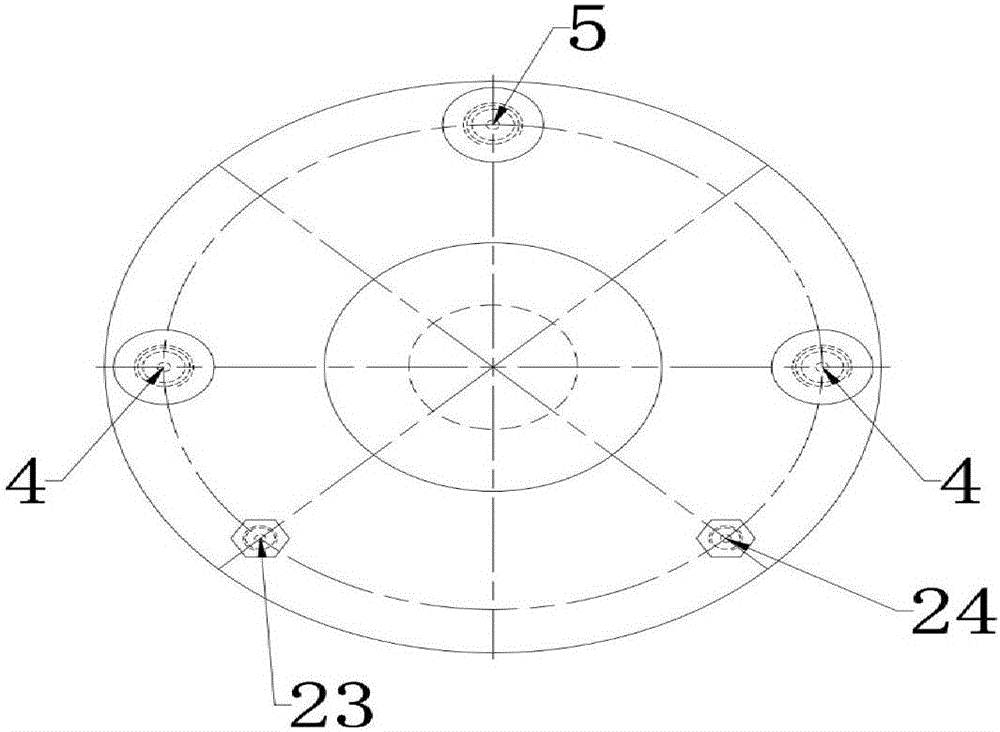

[0049] see figure 1 , figure 2 .

[0050] The utility model relates to a dynamic test device for sealing capacity of a cement sheath, which includes a working platform and a test main body.

[0051] The working platform has a computer, and the computer is provided with a pressure and temperature control terminal.

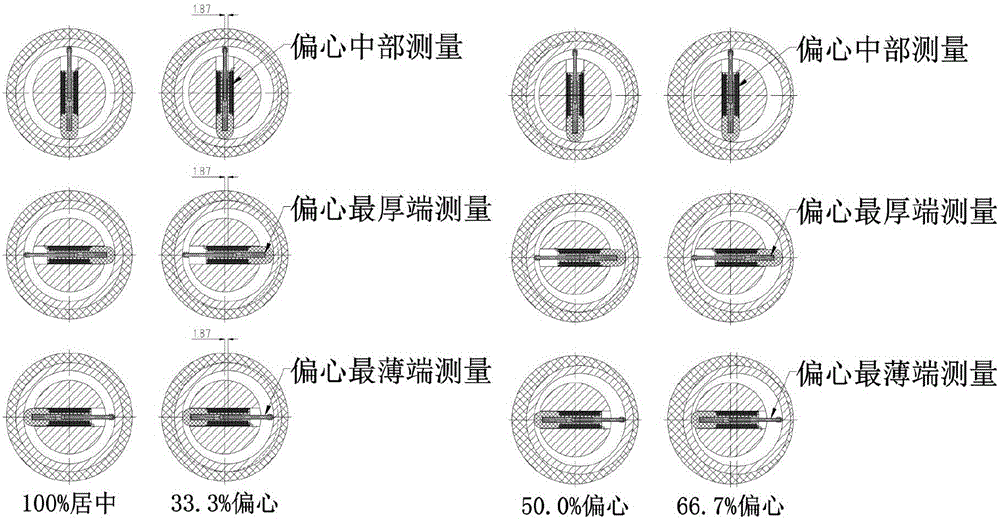

[0052] The test body is located on the bracket. The outside of the test body is the metal cover 6 and the insulation layer 7. The upper and lower parts are the kettle cover, and the middle part is the kettle body. The inside of the kettle body is the simulated formation 12-cement sheath 10-casing 13 from the outside to the inside. The simulated formation 12 is equipped with a circumferential displacement meter 14 and an acoustic wave receiving probe 11, and the annular space between the simulated formation and the casing is an annular space for cement she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com