Producing technology of glitz-resistant lens and vehicle

A production process and anti-glare technology, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as driving safety hazards, low reliability, and complex layout processes, so as to improve reliability, simplify production processes, and simplify processing processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The core of this specific embodiment is to provide an anti-glare lens manufacturing process, which can satisfy the anti-glare of the mirror surface, simplify the production process, improve product reliability, and solve the problems in the prior art.

[0026] Hereinafter, the embodiment will be described with reference to the drawings. In addition, the embodiments shown below do not have any limiting effect on the content of the invention described in the claims. In addition, the whole content of the structure shown in the following embodiment is not limited to what is necessary for the solution of the invention described in the claim.

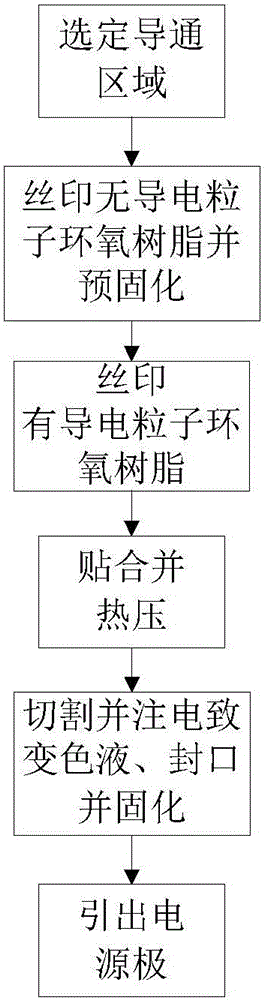

[0027] The manufacturing process of the anti-glare lens provided by this specific embodiment may include the steps of: firstly selecting a first conductive area and a second conductive area on the upper glass and the lower glass, respectively, and selecting so that the two layers of glass are attached when they are attached to each oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com