Non-probabilistic time-variant reliability solution method of composite laminated plate

A composite material and laminate technology, which is used in special data processing applications, instruments, electrical digital data processing, etc., can solve the damage of plate structure, does not consider the correlation between the previous period and the next moment, and the reliability of the time point cannot be complete. And accurately describe the structural reliability and other issues, to reduce the dependence, improve the accuracy and rationality of the solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

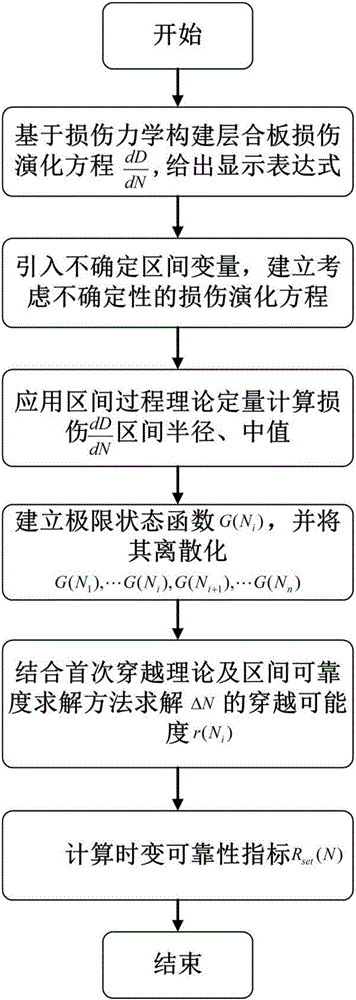

[0034] Such as figure 1 As shown, the present invention proposes a non-probabilistic time-varying reliability optimization method for composite laminates, comprising the following steps:

[0035] (1) Using the interval vector x∈x I =(σ,D cr ,A,B,C) reasonably characterize the structural uncertainty under the condition of poor information and less data, so there are:

[0036]

[0037]

[0038]

[0039]

[0040]

[0041]

[0042]

[0043]

[0044]

[0045]

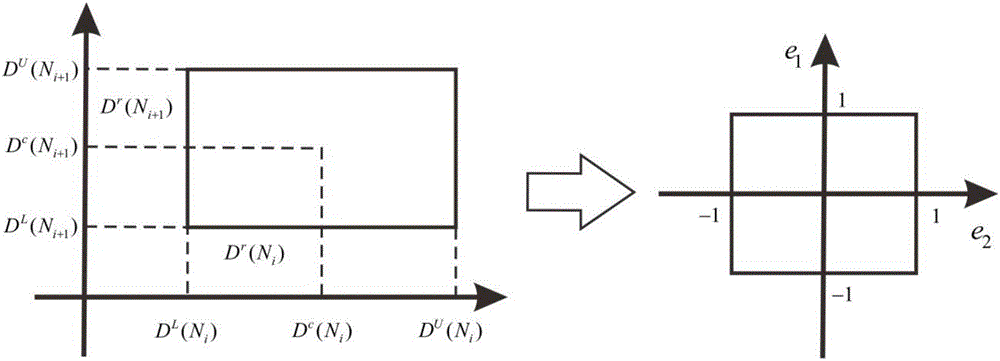

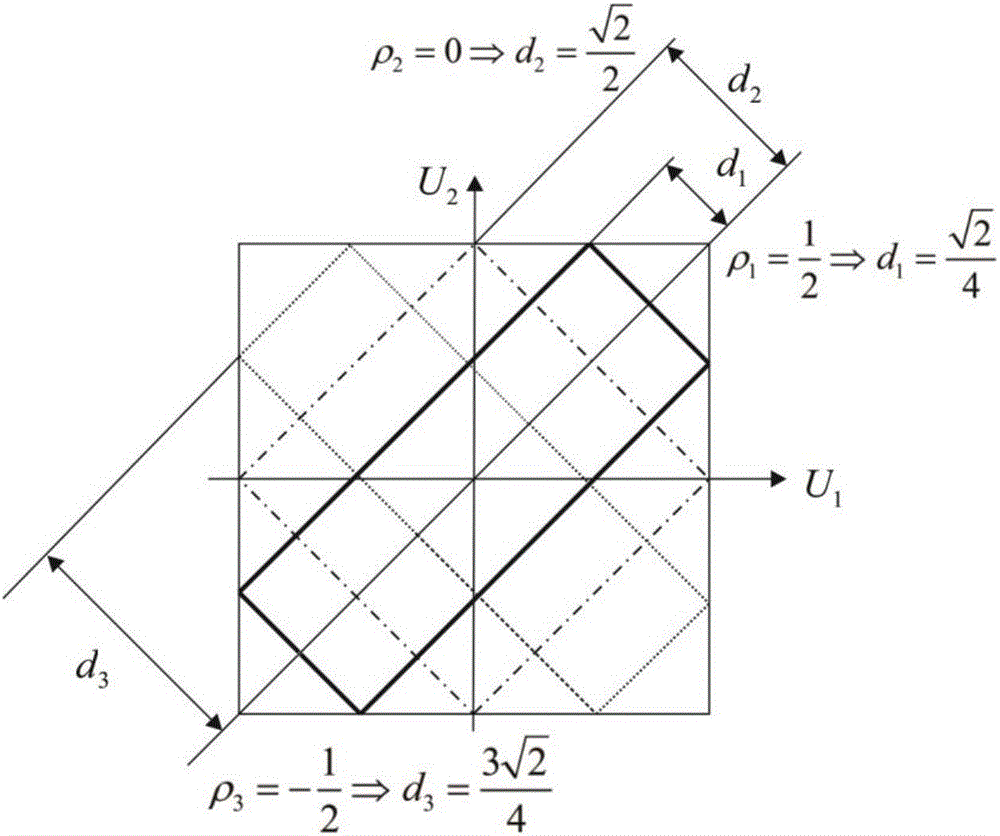

[0046] Among them, the structural strength R can be expressed as an interval variable, the superscript U represents the upper bound of the parameter value, the superscript L represents the lower bound of the parameter value, the superscript c represents the center value, the superscript r represents the radius, and the uncertainty parameter vector x can be exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com