Risk prediction method for accident gate closure of hydraulic ship lift

A technology of risk prediction and ship lift, applied in the field of navigable hydraulics, can solve the problems of upward sliding of the cabin, insufficient braking force, and reduced buoyancy of the balance weight, so as to ensure the safety of operation and prevent risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

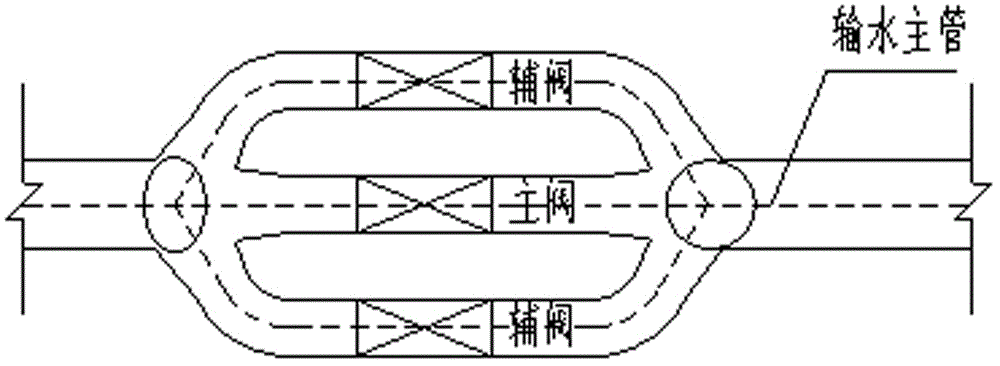

[0029] Such as figure 2 As shown, the risk prediction method of the hydraulic ship lift accident on the lock accident of the present invention comprises the following steps:

[0030] Step 1: According to the torque balance condition of the drum, combined with the braking force of the drum brake and parameters such as the size of the drum, the shaft, and the balance weight, the braking force just reaches the critical value V of the shaft water body change of the design value of the braking force of the drum brake 1j . The design value of the braking force is the maximum braking force that can be provided.

[0031] Reel moment balance condition: braking torque T of the brake z R z It can resist the change of the tension moment of the steel wire rope on the balance weight side caused by the change of the shaft water body V which is Once the braking force T of the brake z Reach the braking force design value T zmax , the reel is in the critical equilibrium condition, an...

Embodiment 2

[0041] The implementation case of the present invention is the Jinghong hydraulic ship lift. The calculation value obtained by using the risk prediction method of the accidental lock accident working condition of the present invention is compared with the actual value measured by the project. The results are as follows:

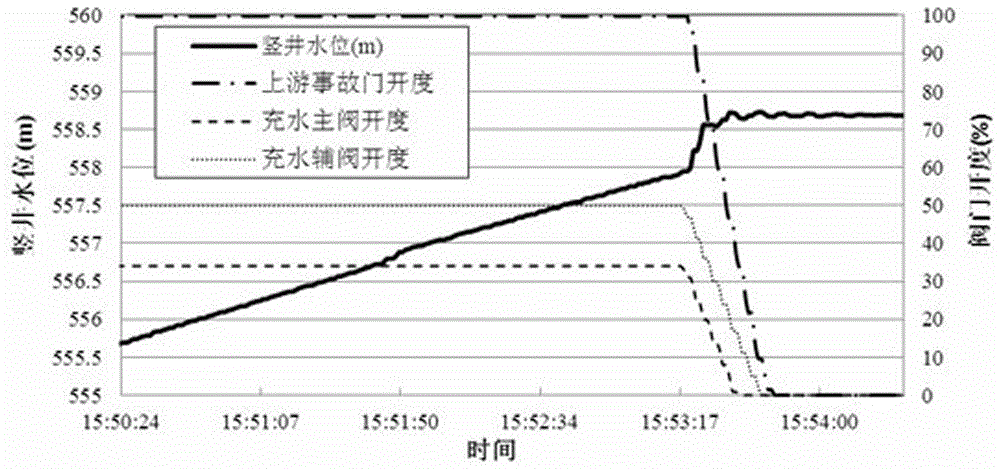

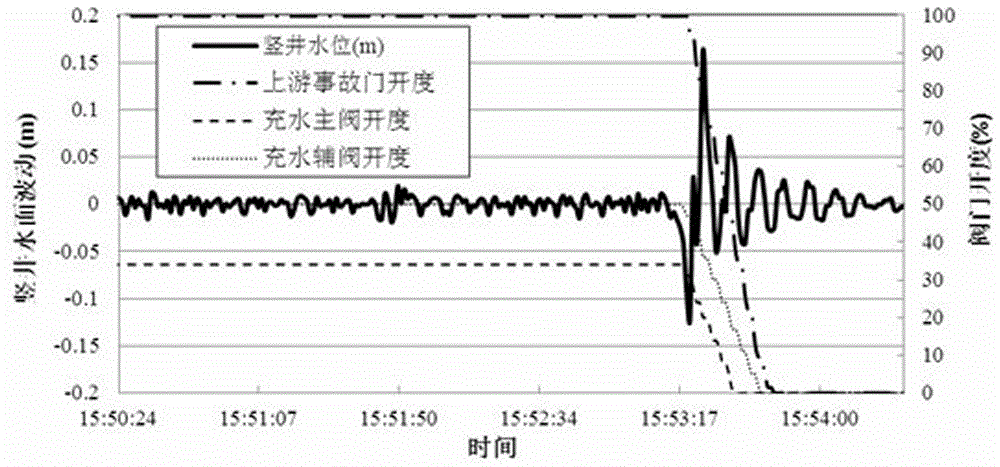

[0042] (1) The water-filled cabin of the vertical shaft goes down and accidentally locks up

[0043] In a certain water-filled downward working condition, the brake is suddenly locked, and the valve closing and door falling procedures are started at the same time. For vertical shaft water level change, vertical shaft water level fluctuation, and flow rate, see Figure 4 ~ Figure 6 , the water level of the shaft rises by 0.8m (557.9m~558.7m) after the brake is locked, and the actual increase in the water body of the shaft is 38.24m 3 .

[0044] (2) Accidental upper lock of the vertical shaft discharge ship compartment

[0045] In a certain water discharge u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com