Power generation system for solid oxide fuel cell

A solid oxide and power generation system technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as difficult flow control, long start-up time, explosion hazards, etc., to reduce the possibility of mutual cross-influence High performance, reasonable structure and layout, stable function

Active Publication Date: 2017-05-31

NINGBO SOFCMAN ENERGY TECH CO LTD

View PDF7 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the U.S. Patent US2012/0178003A1, a process flow and hot zone framework of an SOFC power generation system is provided. The system has the following problems: 1) In the hot zone framework of the SOFC power generation system, the air preheater, the reformed feed preheater, Heat exchangers such as vaporizers are integrated in the hot zone. This structure is suitable for the design of small-scale monomer systems such as tens of kilowatts of SOFC power generation systems. The layout of the hot zone of the power generation system cannot be arranged in this way. Due to heat exchange needs and volume problems, various heat exchangers are not suitable for all integration into the hot zone.

One of the disadvantages of this method is that the flow of fuel at high tempe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

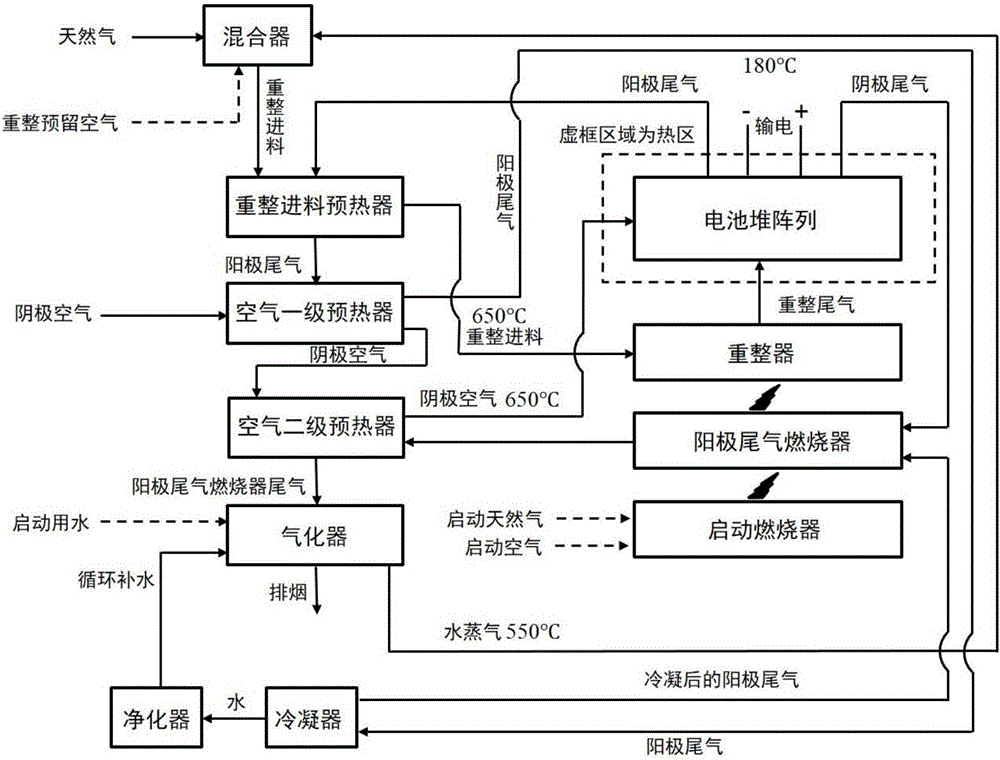

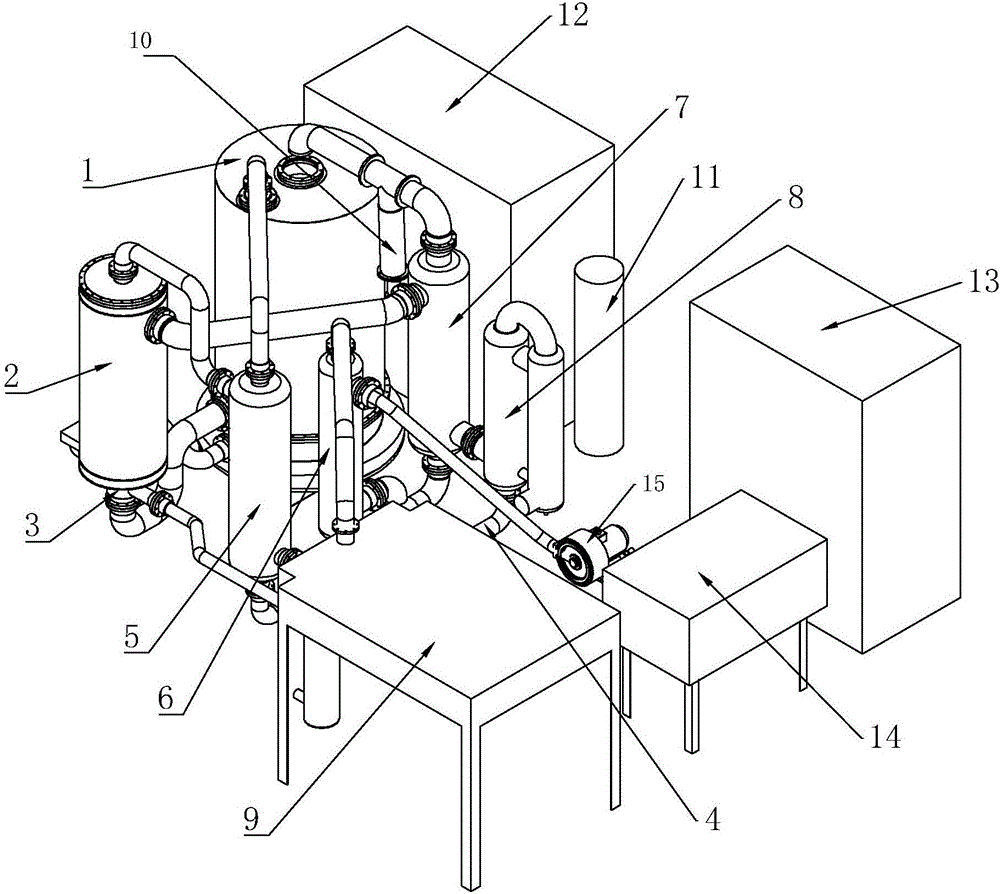

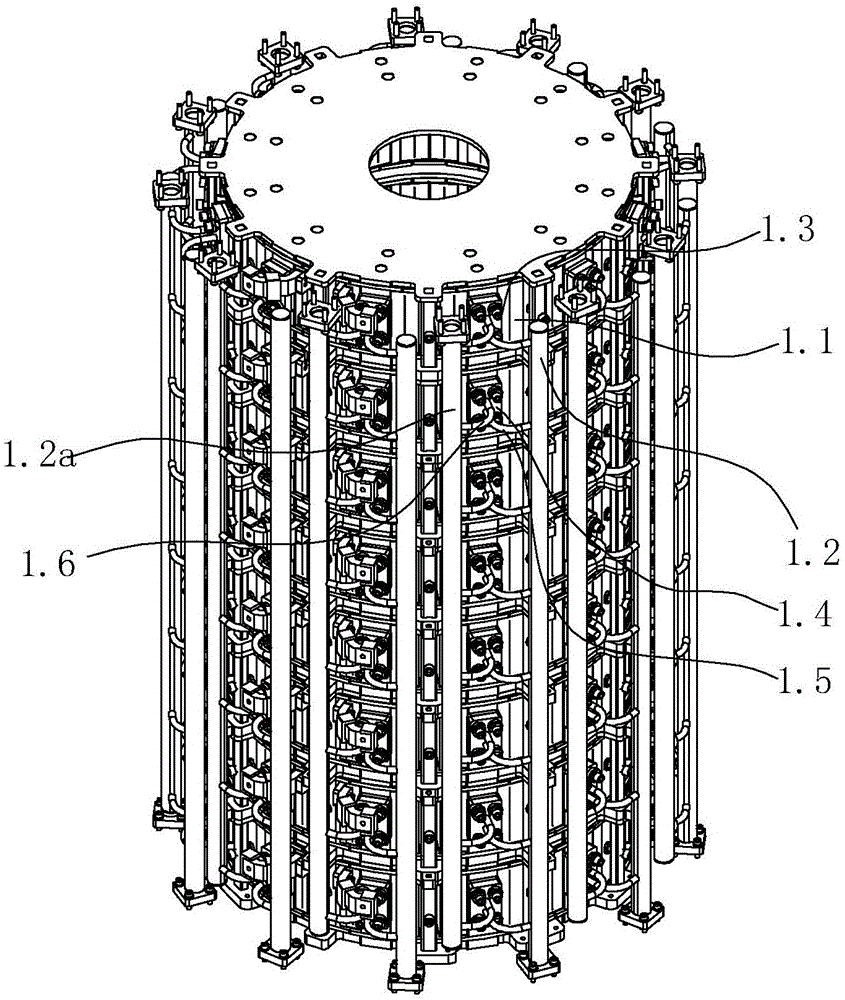

A power generation system for a solid oxide fuel cell comprises a hot area, a reformer, a start-up burner, a positive pole tail gas burner, a mixer and a heat transfer component, wherein the hot area comprises a voltaic pile array and a corresponding gas distribution pipeline, the reformer, the heat transfer component and the hot area are discretely arranged, and connected with one another through the pipeline, the heat transfer component comprises a reforming feed preheater, an air first level preheater, an air second level preheater, a vaporizer and a condenser, and the mixer is provided with an inlet for reforming preserved air. According to the power generation system, all main components are discretely arranged but not centralized in the hot area, the combined difficulty of all the components is reduced, the overall layout is convenient, the possibility of mutual cross influence is reduced simultaneously, and all the components are convenient to play a part stably; the power generation system has the advantages of reasonable structural layout, convenient assembly and disassembly, stable function, reasonable heat transfer and the like, and is suitable for layout and for building the power generation system for the solid oxide fuel cell with a monomer of 100 kilowatts.

Description

technical field [0001] The invention relates to a solid oxide fuel cell power generation system, in particular to the flow and device layout of the power generation system. Background technique [0002] The solid oxide fuel cell (Solid Oxide Fuel Cell, SOFC) power generation system is a clean and efficient energy conversion system that uses gaseous hydrocarbons such as natural gas, hydrogen, and carbon monoxide as raw materials to convert the chemical energy in the fuel into electrical energy. . Relying on the widely distributed natural gas pipeline network, the SOFC power generation system can be integrated into a distributed power station using natural gas as raw material on a large scale to supply the electricity demand of buildings, factories, communities, etc., and has good commercial prospects. [0003] The basic operation process of the SOFC power generation system is as follows: natural gas is firstly reformed to produce hydrogen, carbon monoxide and other gases, wh...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M8/0662H01M8/0612H01M8/04014

CPCH01M8/04014H01M8/04022H01M8/0618H01M8/0662H01M2008/1293Y02E60/50

Inventor 王蔚国彭军陈涛何长荣牛金奇陈赛虎赵青姜松林郭旻

Owner NINGBO SOFCMAN ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com