Rotor of alternating current permanent magnet servo motor

A technology for permanent magnet servo motors and rotors, which is applied in the direction of magnetic circuit rotating parts, magnetic circuits, electrical components, etc., and can solve problems such as large magnetic flux leakage coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

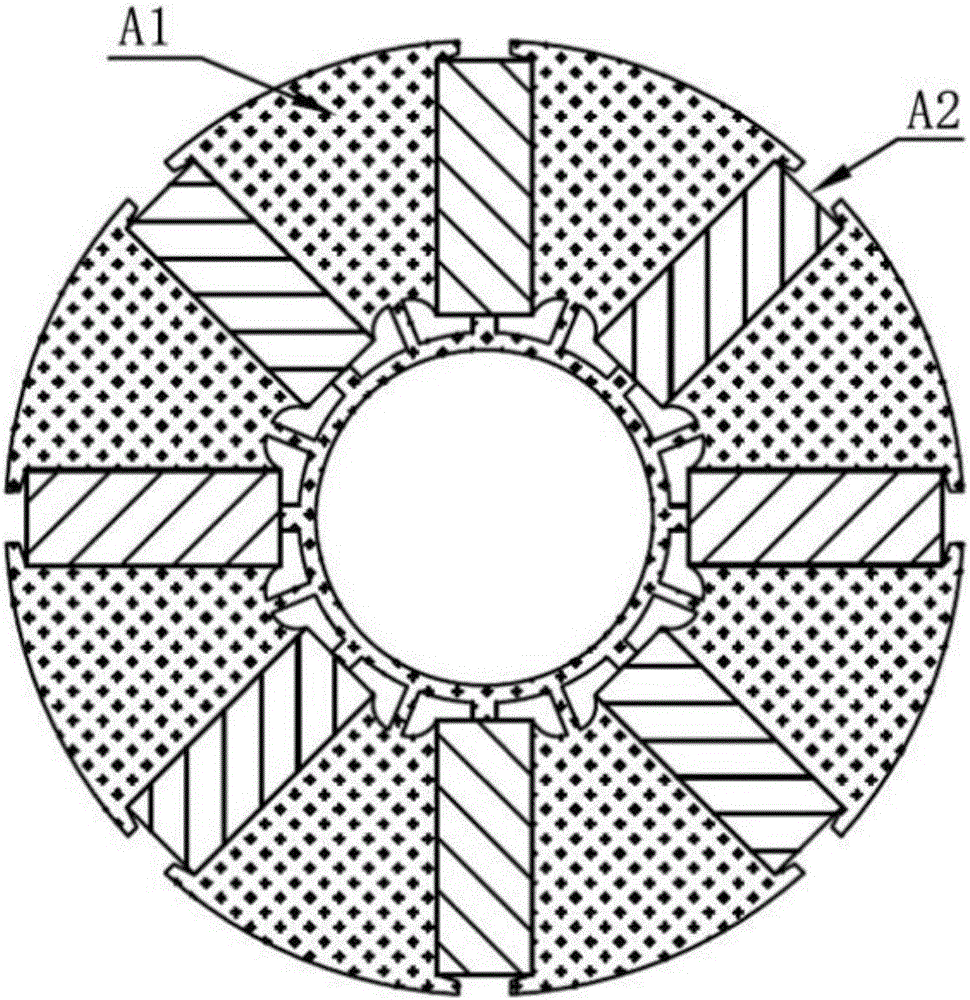

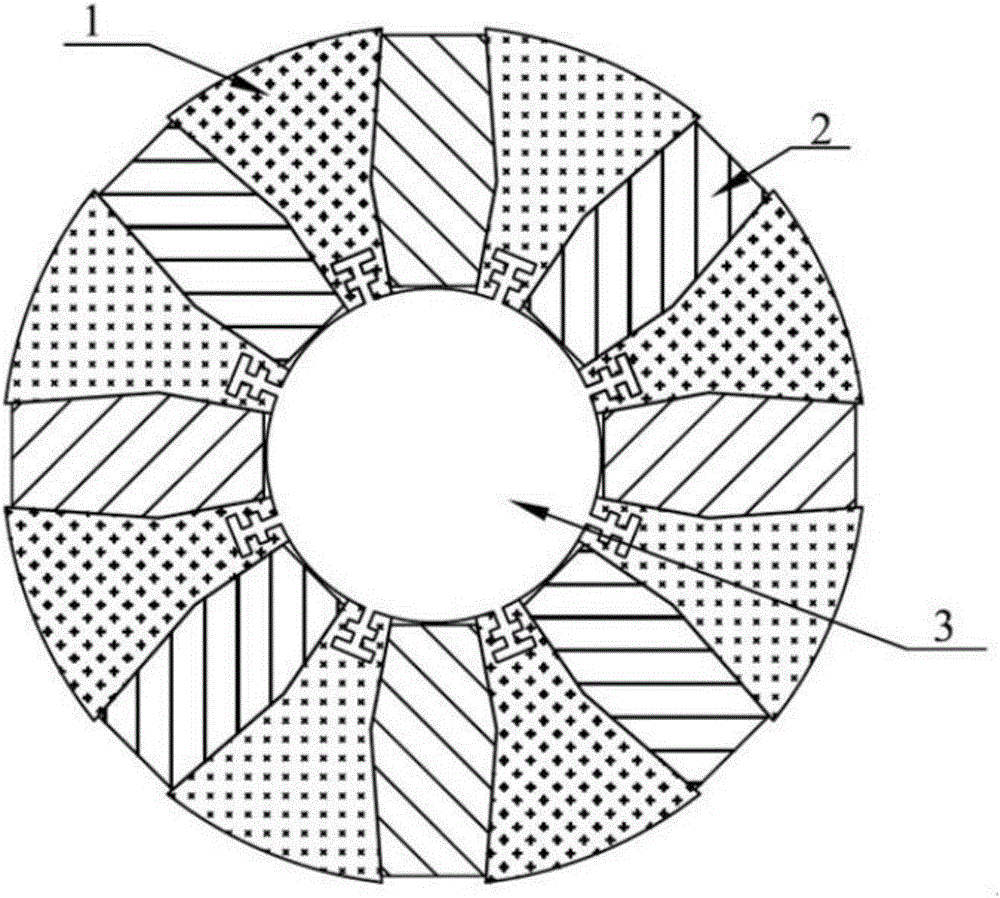

[0021] refer to image 3 and Figure 4 , a rotor of an AC permanent magnet servo motor, including a rotating shaft 3, a plurality of permanent magnets 2 and a plurality of independent iron cores 1, and the independent iron cores 1 are pressed by multiple identical laminations to form a composite core, wherein the laminations It is fan-shaped, and a second-order guide groove 11 is provided at a position close to the rotating shaft 3. The side of the lamination includes two edges 12a, 12b that form an angle with each other. Using a plurality of identical laminations to press the independent iron core 1 is beneficial to reduce the cost of production equipment, and the cost of producing sheet-shaped components is lower than that of producing block-shaped components, which is beneficial to popularization and application of the rotor with this structure.

[0022] The independent iron core 1 is arrayed around the rotating shaft 3. The rotating shaft 3 is a cylinder, and the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com