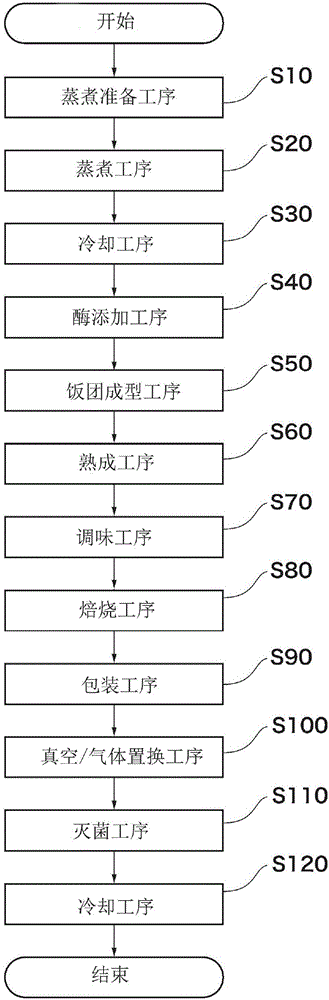

Method for producing cooked rice for long-term preservation and method for producing rice ball for long-term preservation

A technology of long-term preservation and manufacturing method, which is applied in the manufacture of long-term preservation of rice balls and long-term preservation of rice. It can solve the problems of deterioration of food taste and aging of rice, and achieve the effect of not damaging the taste of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

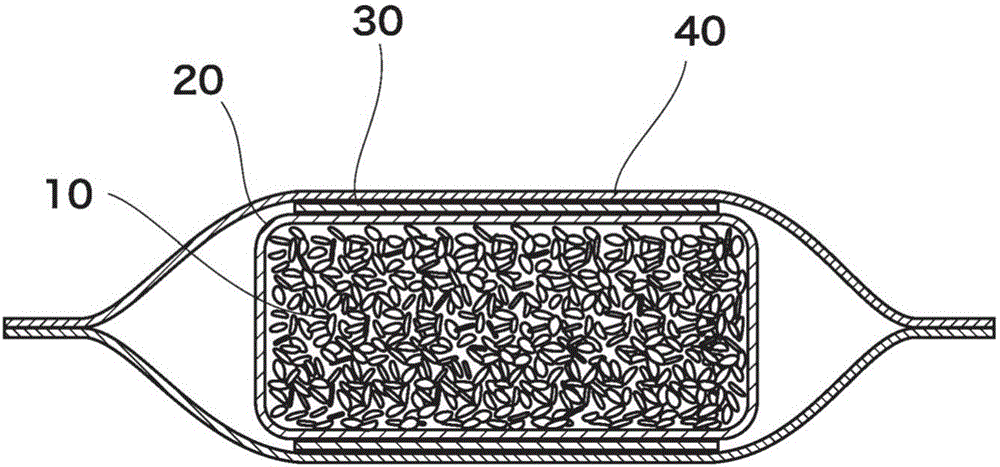

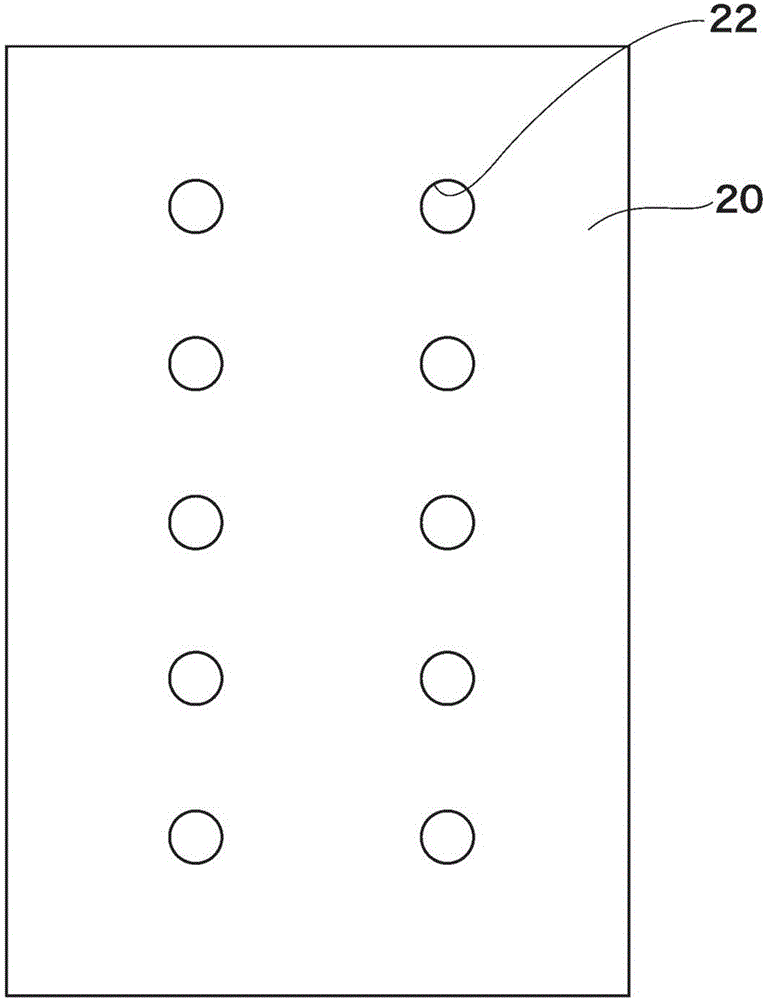

[0064] Prepare a plurality of rice balls obtained by directly molding the rice through the cooking preparation process (S10), the steaming process (S20), and the cooling process (S30) by hand, and by adding 2% by weight of β-amylase to the rice. These two types of onigiri are obtained by mixing and molding by hand. A commercially available aluminum foil was cut out into a rectangle of 80 mm×160 mm, and a plurality of these two kinds of rice balls were individually wrapped with the aluminum foil formed with ten holes of 3 mm in diameter. Wrap it with 100% pure pulp paper from the outside, and put it in an aluminum bag for retort. Simultaneously, a deoxidizer ("Ageless" manufactured by Mitsubishi Gas Chemical: registered trademark) was added between the aluminum bag and the pure pulp 100% paper. Thereafter, after performing vacuum treatment, the aluminum bag is sealed, and a sterilization process (S110) and a cooling process (S120) are performed. The rice balls were taken out ...

Embodiment 2

[0067] For the onigiri formed by mixing β-amylase produced as above, 1) Wrap it with aluminum foil without holes and 100% pure pulp paper and put it in an aluminum bag, 2) Use only aluminum foil with holes Put it in an aluminum bag after wrapping, and 3) wrap it only with 100% pure pulp paper, put it in an aluminum bag, perform vacuum treatment, then seal it, and implement a sterilization process (S110) and a cooling process (S120). On the next day, the aluminum bag was opened and the onigiri were observed.

[0068] 1) Onigiri wrapped in aluminum foil and paper without holes, the surface of the onigiri is sticky due to moisture. 2) In the onigiri wrapped only by the aluminum foil with holes formed, water droplets adhered to the inside of the aluminum bag, and the surface of the onigiri was also sticky. 3) Onigiri wrapped only with 100% pure pulp paper, the 100% pure pulp paper sticks to the surface of the rice ball and is difficult to remove completely. It should be noted th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com