Stability enhancing structure and method for H-shaped section column of dust remover box body

A dust collector and stability technology is applied in the field of the stability enhancement structure of the H-section column of the dust collector box, which can solve the problems of low utilization rate of material strength, instability and damage of the column of the dust collector box, and reduce production costs, etc. Convenient processing and production, improve stable bearing capacity, and improve the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

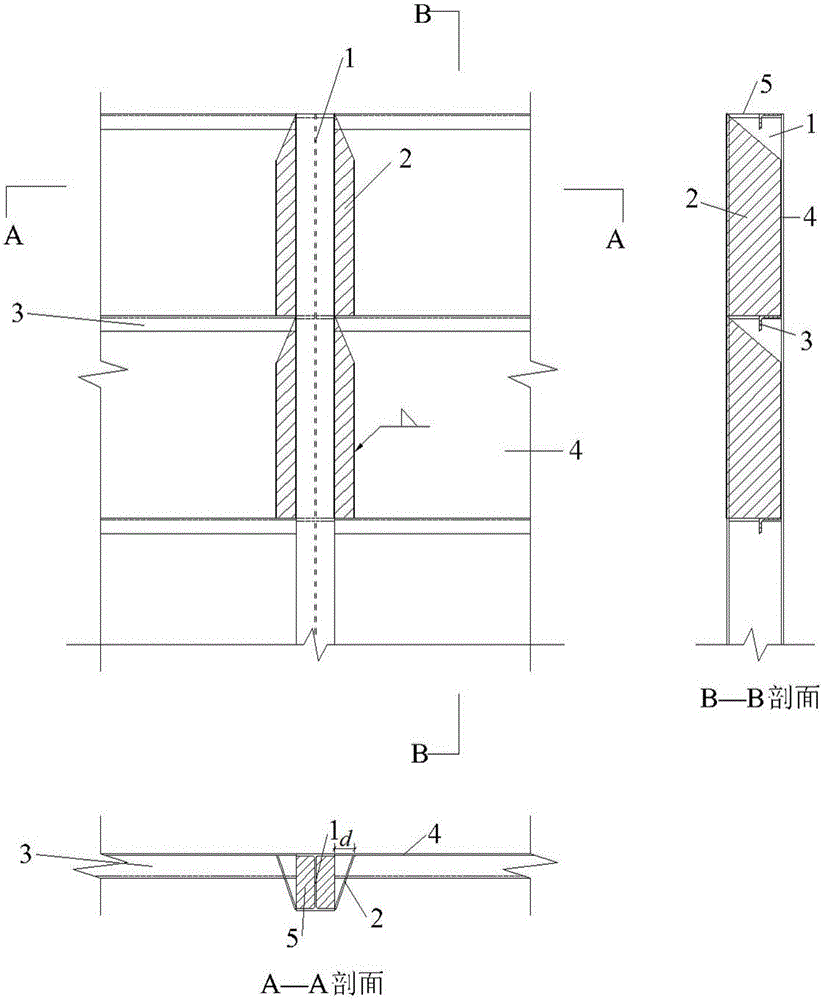

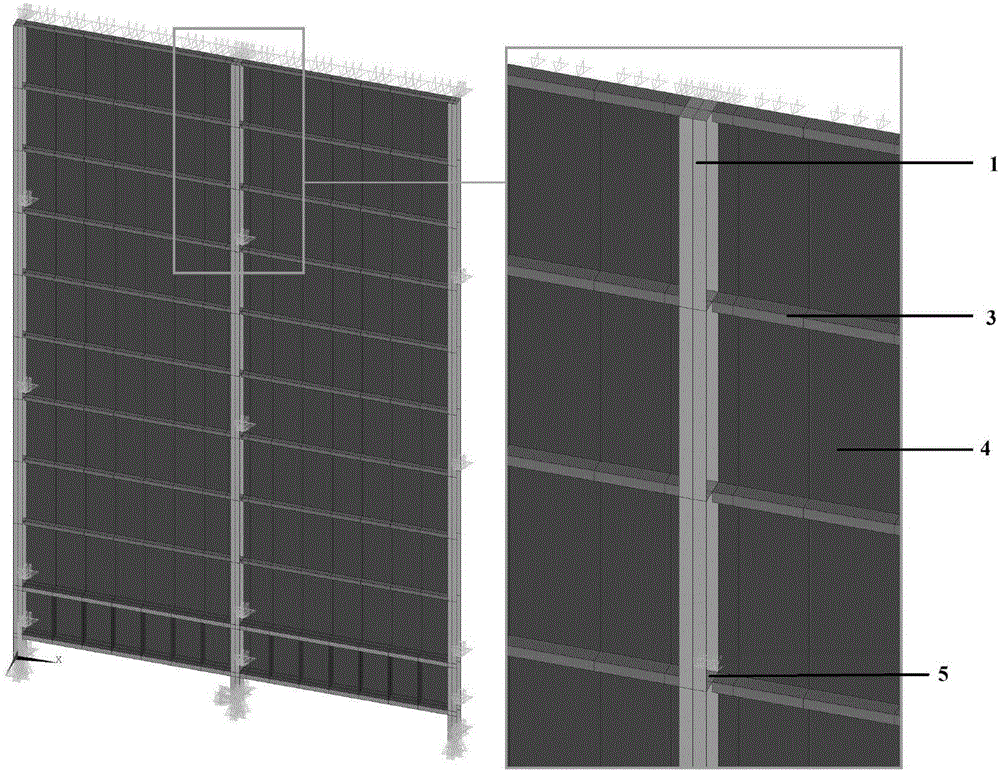

Embodiment 1

[0035] The thickness t of the wall panel of the dust collector box is 7mm, the width w of the wall panel is 3500mm, the spacing s of the angle steel stiffener is 1170mm, and a horizontal support is provided every three stiffener spacings (the spacing of the lateral support is l=3s), the total height of the column H is 11990mm, and the column section is H200mm×150mm×6mm×9mm (section height h×flange width b f × web thickness t w × Flange thickness t f ).

[0036] When the lateral load is small, the initial bending and torsion deformation of the column section is constructed within the range of 0-0.08l below the column top; when the lateral load is large, the initial bending and torsion deformation is constructed within the range of 0.24l-0.32l. Calculate the bearing capacity of the column when the lateral load is 3000Pa and 9000Pa, and the stable bearing capacity before the stability of the column is enhanced is shown in Table 1.

Embodiment 2

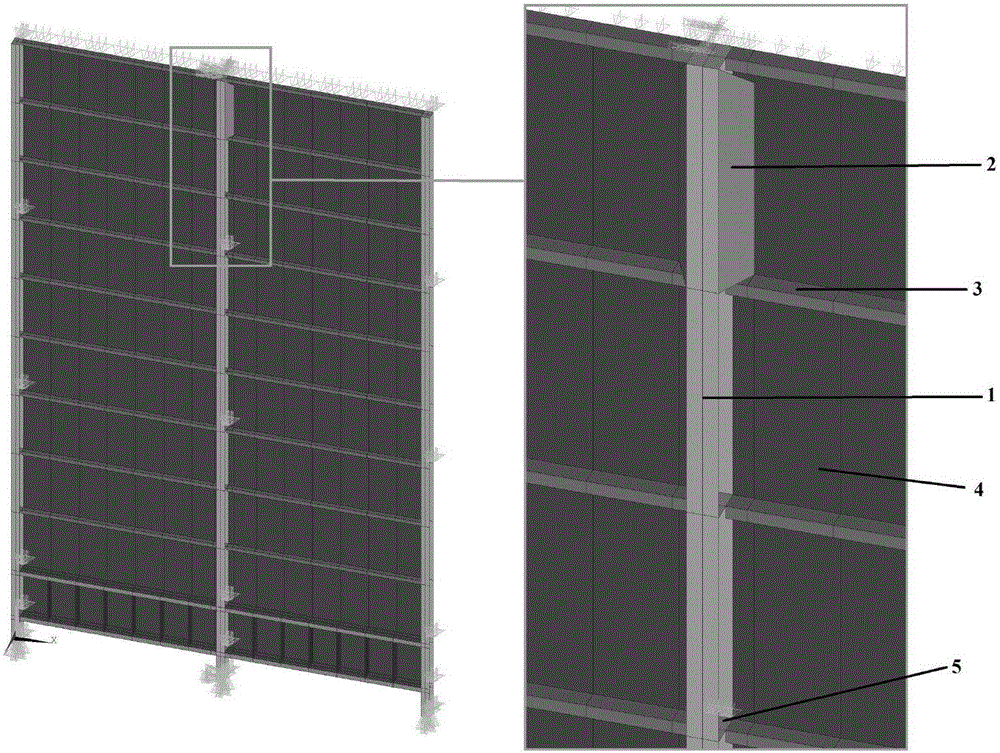

[0038] Using the model parameters in Example 1, the stability-enhancing construction measures are adopted for the column simulation, the distance d between the vertical connection weld of the reinforced steel plate and the wall plate is 0mm from the joint weld of the wall plate and the rear flange of the column, and the thickness of the reinforced steel plate is t s It is 1 times the thickness of the wallboard, and the reinforcement section is the first stiffener section. The stable bearing capacity after the column stability is enhanced is shown in Table 1.

Embodiment 3 and Embodiment 4

[0040] Compared with Example 2, Embodiment 3 and Embodiment 4 only change the distance d between the vertical connection weld between the reinforced steel plate and the wall panel and the connection weld between the wall panel and the rear flange of the column in the stability-enhancing structure, and the specific construction parameters and the stability of the column The bearing capacity comparison is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com