Ceramic cutting-milling combined-type plane processing method based on crack propagation effect

A crack propagation and composite technology, which is applied in the field of rough machining of engineering ceramics, can solve the problems of large grinding wheel wear, low processing efficiency, and unsuitable fine grinding, etc., and achieve the effect of reducing grinding wheel wear and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described in detail below through specific embodiments and accompanying drawings.

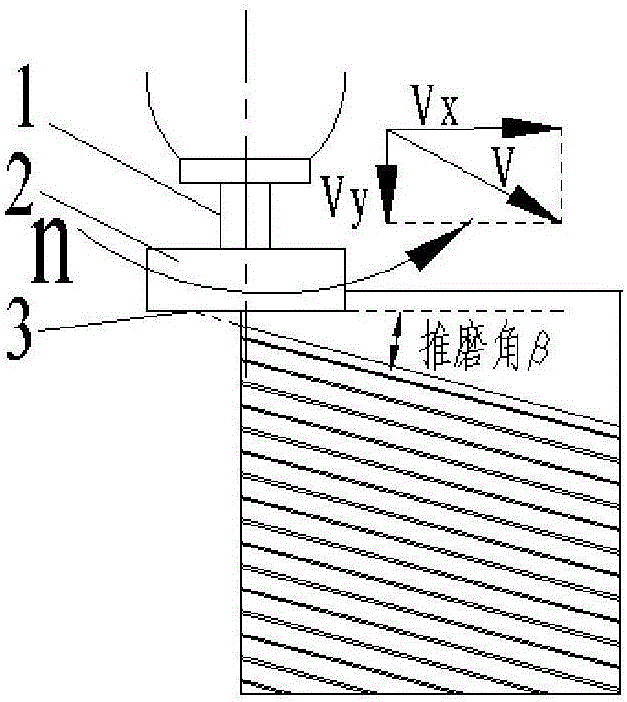

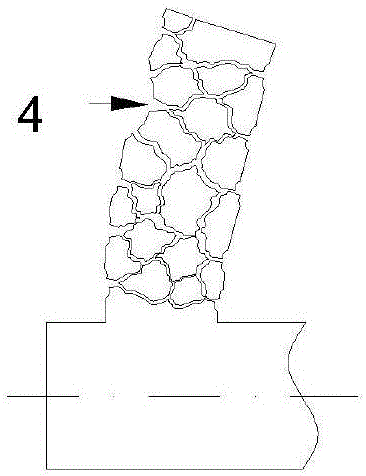

[0020] The present invention proposes a ceramic cutting-push-grinding compound surface processing method based on the crack propagation effect, which is improved on the basis of the cylindrical surface processing method, and is a large margin rough processing method for hard and brittle materials such as engineering ceramics , by pre-processing oblique grooves on the flat ceramic workpiece and pre-fabricating micro-crack defects, reasonably setting the oblique processing angle of the grinding pre-processing flange, taking advantage of the characteristics that the cracks of hard and brittle materials are easy to expand, in the tool Under the action of pushing, the crack expands instantaneously, and finally drives the cracks to be networked and broken, so as to realize the removal of the flange.

[0021] The described ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com