A kind of anti-drilling fabric

An anti-drilling and fabric technology, applied in the direction of singeing, protective clothing, fabric elongation, etc., can solve the problems of affecting appearance, airtightness, poor hygroscopicity, etc., and achieve the effect of good moisture absorption and ventilation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

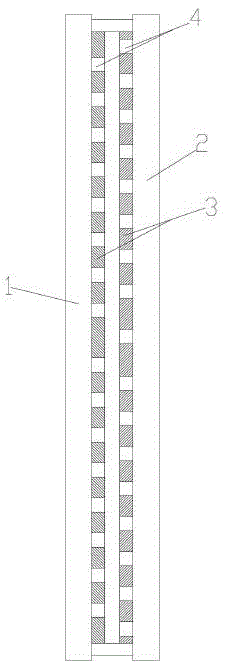

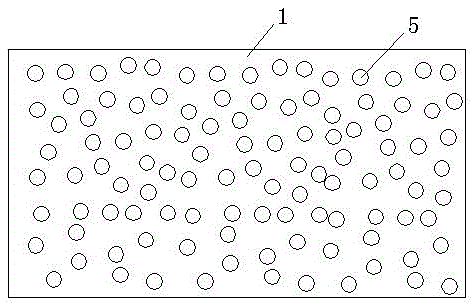

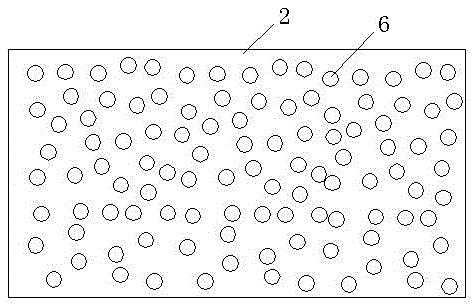

[0019] see Figure 1 to Figure 3 , the present invention relates to an anti-drilling wool fabric, the fabric has an inner fabric 1 and an outer fabric 2, and a glue layer 3 is sprayed on the opposite surface of the inner fabric 1 and the outer fabric 2, and the glue layer 3 is Ventilation holes 4 are provided, and the positions of the air holes 4 on the glued layer of the inner layer fabric 1 and the air holes 4 on the glued layer of the outer layer fabric 2 are interlaced, and the peripheries of the inner layer fabric 1 and the outer layer fabric 2 are stitched together , the inner fabric 1 is provided with lower air holes 5 , and the outer fabric 2 is provided with upper air holes 6 .

[0020] The technological method of making a kind of anti-drilling fabric is:

[0021] 1) Yarn variety design:

[0022] Choose wool fiber, cashmere fiber, bamboo charcoal polyester fiber and stainless steel fiber, anti-pilling treatment, enzyme treatment and softening treatment for wool fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com