Printing and dyeing method of graphene chinlon-cotton woven fabric

A technology of graphene nylon-cotton woven fabrics, which is applied in the printing and dyeing field of graphene nylon-cotton woven fabrics to achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

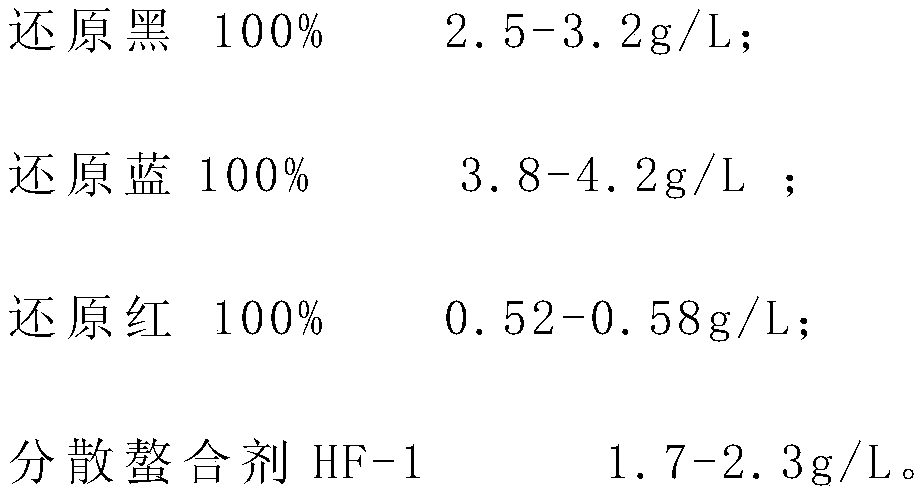

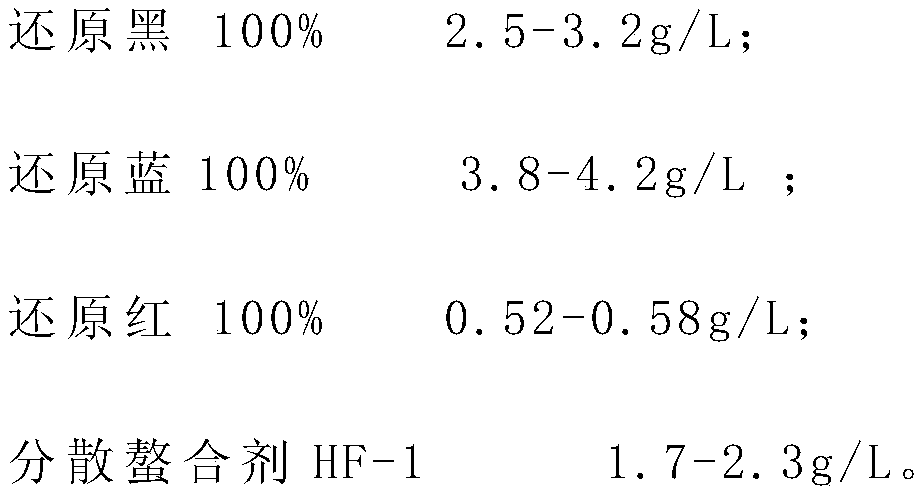

Embodiment 1

[0059] A printing and dyeing method for graphene nylon / cotton woven fabrics, comprising the following steps: seam turning → desizing and oxygen bleaching → shaping → mercerizing → dyeing with a primer → baking → reduction soaping machine steaming and color fixing → stretching → pre-setting shrink;

[0060] (1) Oxygen bleaching process for desizing

[0061] Desizing process: caustic soda 29g / L; desizing agent 6g / L, dispersing and chelating agent HF-1 2g / L; temperature: 102°C; time: 50min;

[0062]Oxygen bleaching process: caustic soda 3g / L, hydrogen peroxide 6g / L, hydrogen peroxide stabilizer 5g / L, oxygen bleaching agent 6g / L, dispersing chelating agent HF-1 2g / L; temperature: 95°C; time: 40min;

[0063] (2) Shaping process

[0064] Temperature: 210°C; Time: 25s; Width: Add 5cm to the finished product;

[0065] (3) Mercerizing process

[0066] Caustic soda: 215g / L; Time: 55 seconds; Width: finished product width;

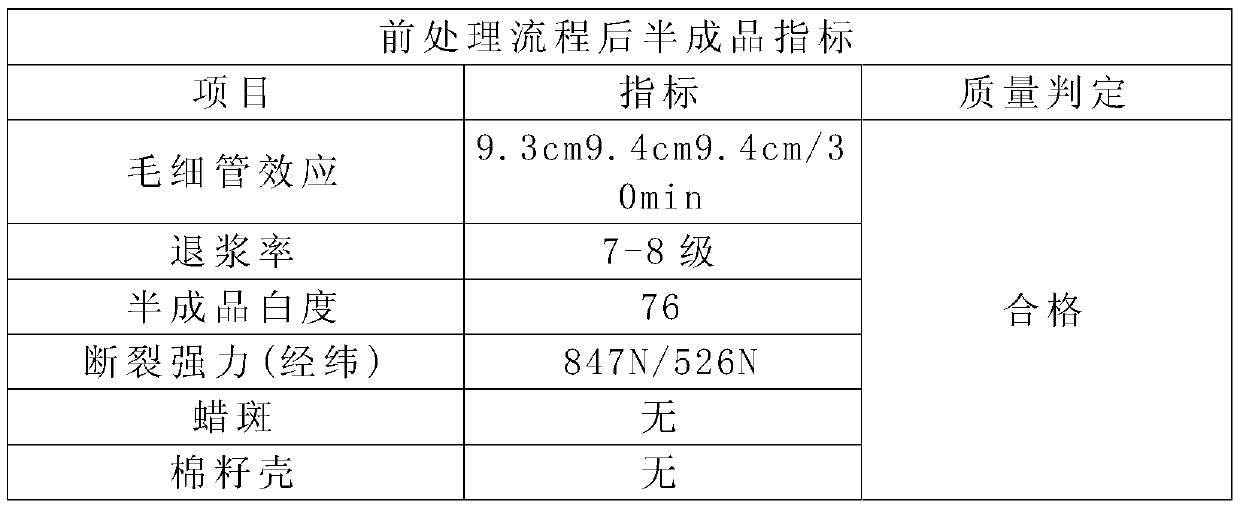

[0067] The above-mentioned steps (1)-(3) are pre-treatment...

Embodiment 2

[0097] A printing and dyeing method for graphene nylon / cotton woven fabrics, comprising the following steps: seam turning → desizing and oxygen bleaching → shaping → mercerizing → dyeing with a primer → baking → reduction soaping machine steaming and color fixing → stretching → pre-setting shrink;

[0098] (1) Oxygen bleaching process for desizing

[0099] Desizing process: caustic soda 28g / L; desizing agent 5g / L, dispersing and chelating agent HF-1 2.2g / L; temperature: 100°C; time: 50min;

[0100] Oxygen bleaching process: caustic soda 4g / L, hydrogen peroxide 5.5g / L, hydrogen peroxide stabilizer 6g / L, oxygen bleaching agent 6g / L, dispersing chelating agent HF-1 2g / L; temperature: 90°C; time: 45min;

[0101] (2) Shaping process

[0102] Temperature: 215°C; Time: 20s; Width: add 5cm to the finished product;

[0103] (3) Mercerizing process

[0104] Caustic soda: 210g / L; Time: 60 seconds; Width: finished product width;

[0105] The above-mentioned steps (1)-(3) are pre-trea...

Embodiment 3

[0129] A printing and dyeing method for graphene nylon / cotton woven fabrics, comprising the following steps: seam turning → desizing and oxygen bleaching → shaping → mercerizing → dyeing with a primer → baking → reduction soaping machine steaming and color fixing → stretching → pre-setting shrink;

[0130] (1) Oxygen bleaching process for desizing

[0131] Desizing process: caustic soda 30g / L; desizing agent 5.5g / L, dispersing and chelating agent HF-1 1.8g / L; temperature: 104°C; time: 50min;

[0132] Oxygen bleaching process: caustic soda 3.5g / L, hydrogen peroxide 5g / L, hydrogen peroxide stabilizer 5.5g / L, oxygen bleaching agent 6g / L, dispersing chelating agent HF-1 2g / L; temperature: 100°C; time: 35min;

[0133] (2) Shaping process

[0134] Temperature: 205°C; Time: 30s; Width: add 5cm to the finished product;

[0135] (3) Mercerizing process

[0136] Caustic soda: 220g / L; Time: 50; Width: finished product width;

[0137] The above-mentioned steps (1)-(3) are pre-treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com