Variable torque operating lever

A joystick and variable torque technology, applied in the field of game controllers, can solve the problems of unadjustable weight distribution, difficulty in adapting to the feel of analog joysticks, inconvenient operation, etc., so as to increase work reliability, avoid slippage, and improve displacement The effect of sweat efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

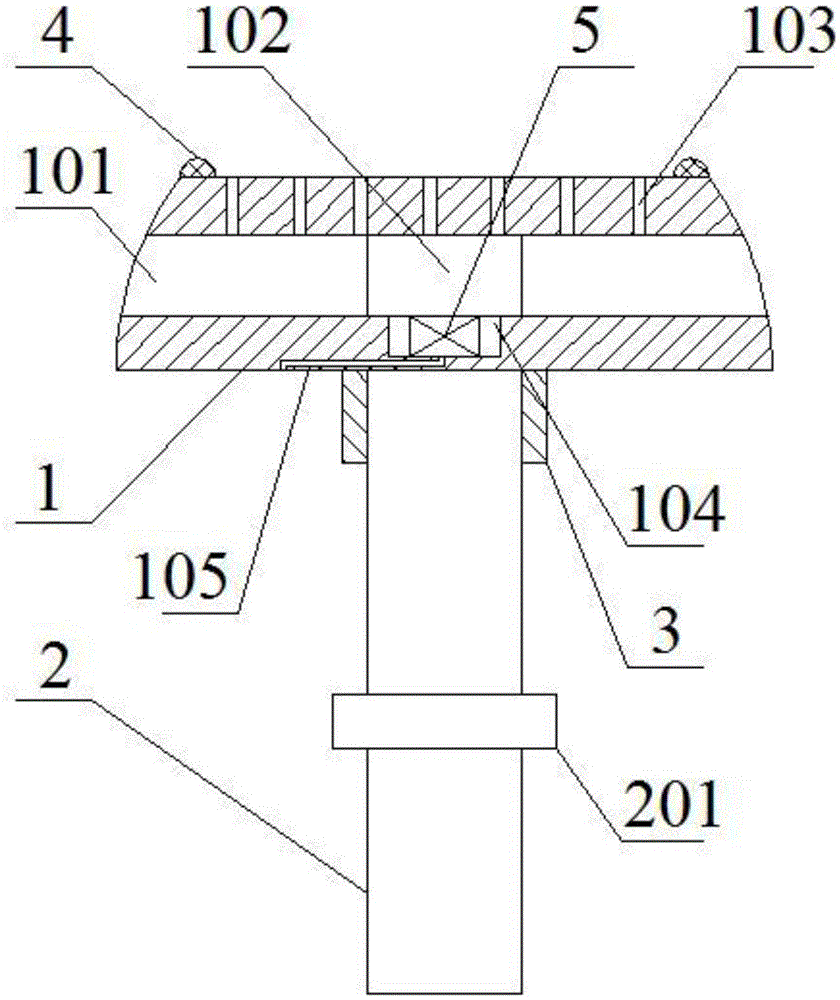

[0027] Such as figure 1 As shown, the variable torque operating lever includes a rocker cap 1, a connecting rod 2 and an air pump 5; the top and bottom of the rocker cap 1 are planes, and a first horizontal through hole 101 is opened in the rocker cap 1, and the first horizontal through hole 101 is opened in the rocker cap 1. Both ends of the hole 101 communicate with the external space, and a second horizontal through hole 102 is provided in the rocker cap 1, and both ends of the second horizontal through hole 102 communicate with the external space. The first horizontal through hole 101 and the The second horizontal through holes 102 cross each other, the first horizontal through holes 101 and the second horizontal through holes 102 are on the same horizontal plane and are perpendicular to each other; The vertical small hole 103 connected by the through hole 102; the connecting rod 2 is arranged vertically, and the top of the connecting rod 2 is connected with the bottom cen...

Embodiment 2

[0031] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes a screw sleeve 3, the screw sleeve 3 is arranged at the bottom center of the rocker cap 1, the top of the connecting rod 2 is provided with external threads, and the connecting rod 2 The top of the top is threadedly connected with the bottom of the rocker cap 1 through a screw sleeve 3 .

[0032] The top of the connecting rod 2 is threadedly connected with the bottom of the rocker cap 1 through a screw sleeve 3, so that the rocker cap 1 can be removed, thereby cleaning the rocker cap 1.

Embodiment 3

[0034] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the diameter of the vertical small hole 103 is 0.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com