High-efficiency drilling equipment for hardware

A drilling equipment and hardware technology, applied in drilling/drilling equipment, metal processing equipment, boring/drilling, etc., can solve the problem of affecting the use of hardware, inconvenient manual drilling, and different drilling positions And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

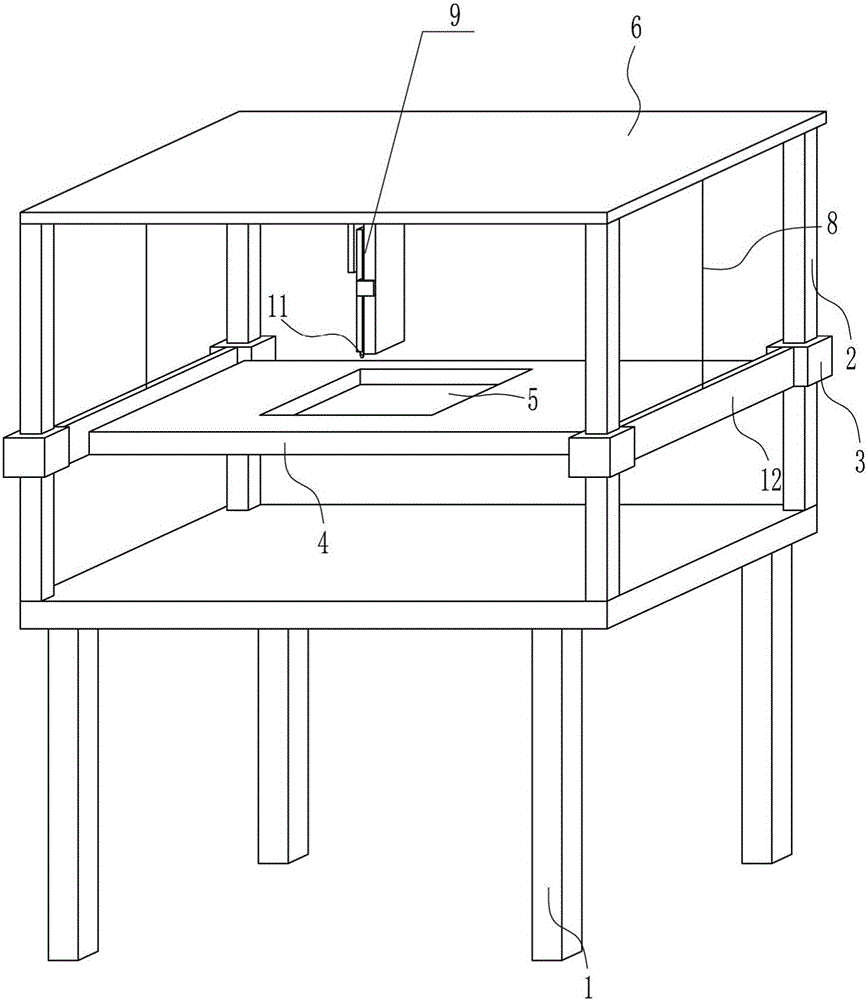

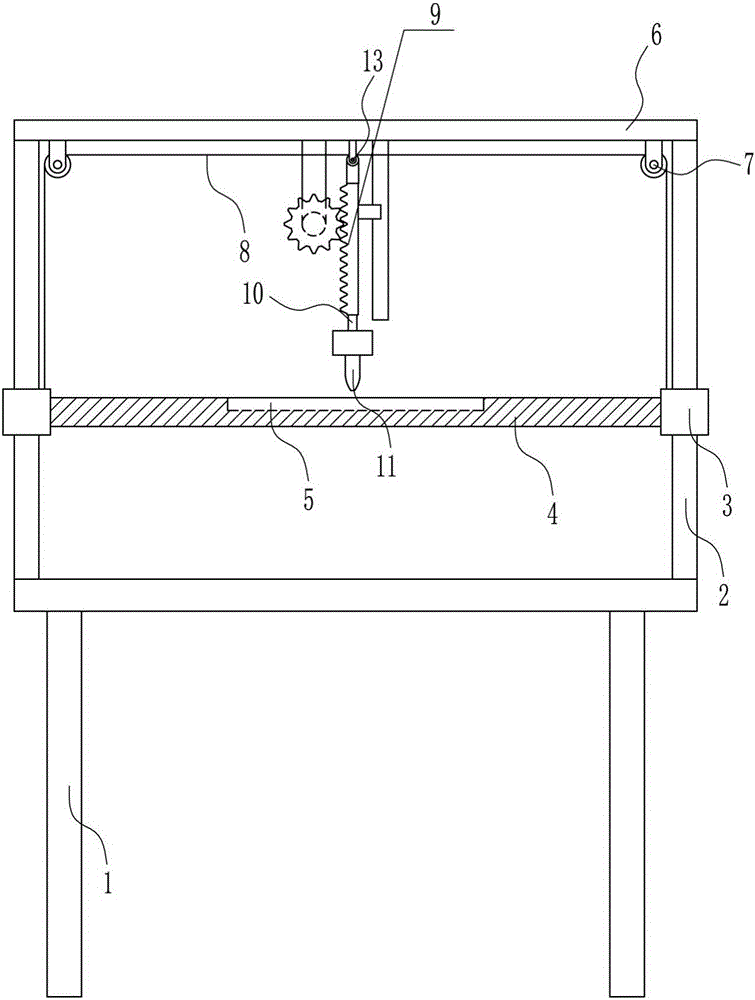

[0036] A hardware efficient drilling equipment, such as Figure 1-8 As shown, it includes a workbench 1, a guide rod 2, a guide sleeve 3, a placement plate 4, a top plate 6, a first pulley 7, a pull wire 8, a lifting mechanism 9, a vertical rod 91, a first motor 92, a gear 93, and a rack 94. The first slider 95, the first slide rail 96, the connecting rod 10, the drilling machine 11, the connecting plate 12 and the second pulley 13, the four corners of the top of the workbench 1 are installed with the guide rod 2 by means of bolt connection, The guide rod 2 is arranged vertically, and the sliding sleeve on the guide rod 2 is covered with a guide sleeve 3. A connecting plate 12 is installed between the two left guide sleeves 3 through bolt connection, and a connecting plate 12 is installed between the two right guide sleeves 3. A connecting plate 12 is installed in the way of bolt connection, a placement plate 4 is connected between the two connecting plates 12, a placement gro...

Embodiment 2

[0038] A hardware efficient drilling equipment, such as Figure 1-8 As shown, it includes a workbench 1, a guide rod 2, a guide sleeve 3, a placement plate 4, a top plate 6, a first pulley 7, a pull wire 8, a lifting mechanism 9, a vertical rod 91, a first motor 92, a gear 93, and a rack 94. The first slider 95, the first slide rail 96, the connecting rod 10, the drilling machine 11, the connecting plate 12 and the second pulley 13, the four corners of the top of the workbench 1 are installed with the guide rod 2 by means of bolt connection, The guide rod 2 is arranged vertically, and the sliding sleeve on the guide rod 2 is covered with a guide sleeve 3. A connecting plate 12 is installed between the two left guide sleeves 3 through bolt connection, and a connecting plate 12 is installed between the two right guide sleeves 3. A connecting plate 12 is installed in the way of bolt connection, a placement plate 4 is connected between the two connecting plates 12, a placement gro...

Embodiment 3

[0041] A hardware efficient drilling equipment, such as Figure 1-8 As shown, it includes a workbench 1, a guide rod 2, a guide sleeve 3, a placement plate 4, a top plate 6, a first pulley 7, a pull wire 8, a lifting mechanism 9, a vertical rod 91, a first motor 92, a gear 93, and a rack 94. The first slider 95, the first slide rail 96, the connecting rod 10, the drilling machine 11, the connecting plate 12 and the second pulley 13, the four corners of the top of the workbench 1 are installed with the guide rod 2 by means of bolt connection, The guide rod 2 is arranged vertically, and the sliding sleeve on the guide rod 2 is covered with a guide sleeve 3. A connecting plate 12 is installed between the two left guide sleeves 3 through bolt connection, and a connecting plate 12 is installed between the two right guide sleeves 3. A connecting plate 12 is installed in the way of bolt connection, a placement plate 4 is connected between the two connecting plates 12, a placement gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com