Oil mist removing device for machine tool

A technology of oil mist and machine tools, which is applied in the field of machinery, can solve problems such as poor practicability, and achieve the effects of improving filtering effect, improving convenience, and improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

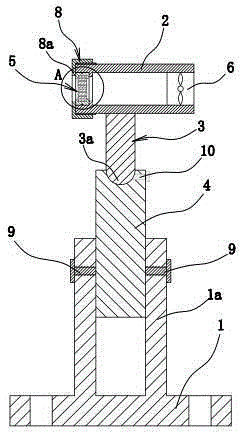

[0024] Such as figure 1 As shown, the oil mist removal device for the machine tool is composed of a base 1, a support cylinder 2, a hinged rod 3, a connecting column 4, a filter screen 5, an exhaust fan 6, and the like.

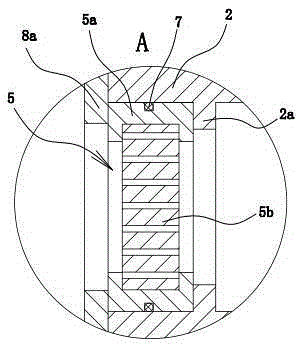

[0025] Wherein, the support cylinder 2 is cylindrical and arranged along the horizontal direction. The suction fan 6 is fixed inside one end of the support cylinder 2 , and the filter screen 5 is fixed inside the other end of the support cylinder 2 . In this example, if figure 1 and figure 2 As shown, the filter screen 5 includes an annular connecting ring 5 and a filter screen 5b fixed in the connecting ring 5 . Wherein, the outer wall of the connecting ring 5 is provided with an annular groove, and an O-shaped sealing ring 7 is arranged in the annular groove, and the outer peripheral surface of the O-shaped sealing ring 7 is against the inner wall of the supporting cylinder 2, so that the connecting ring 5 A more reliable seal is formed between the sup...

Embodiment 2

[0031] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the locking mechanism includes a threaded hole three penetrating through the side wall of the connecting part 1a, a threaded hole four and a screw threaded on the side wall of the connecting column 4 There are several bolts 3 and 4 connected in the threaded holes 3 and they are evenly distributed along the axial direction of the connection part 1a, and the end of the bolts 3 is screwed into one of the threaded holes 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com