Plastic buckle welding tooling for front trim panel of car luggage compartment partition

A technology for welding tooling and decorative panels, which is applied in the field of plastic buckle welding tooling for front trim panels of automobile luggage compartment partitions. It can solve the problems of short connection life and disengagement, and achieve the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

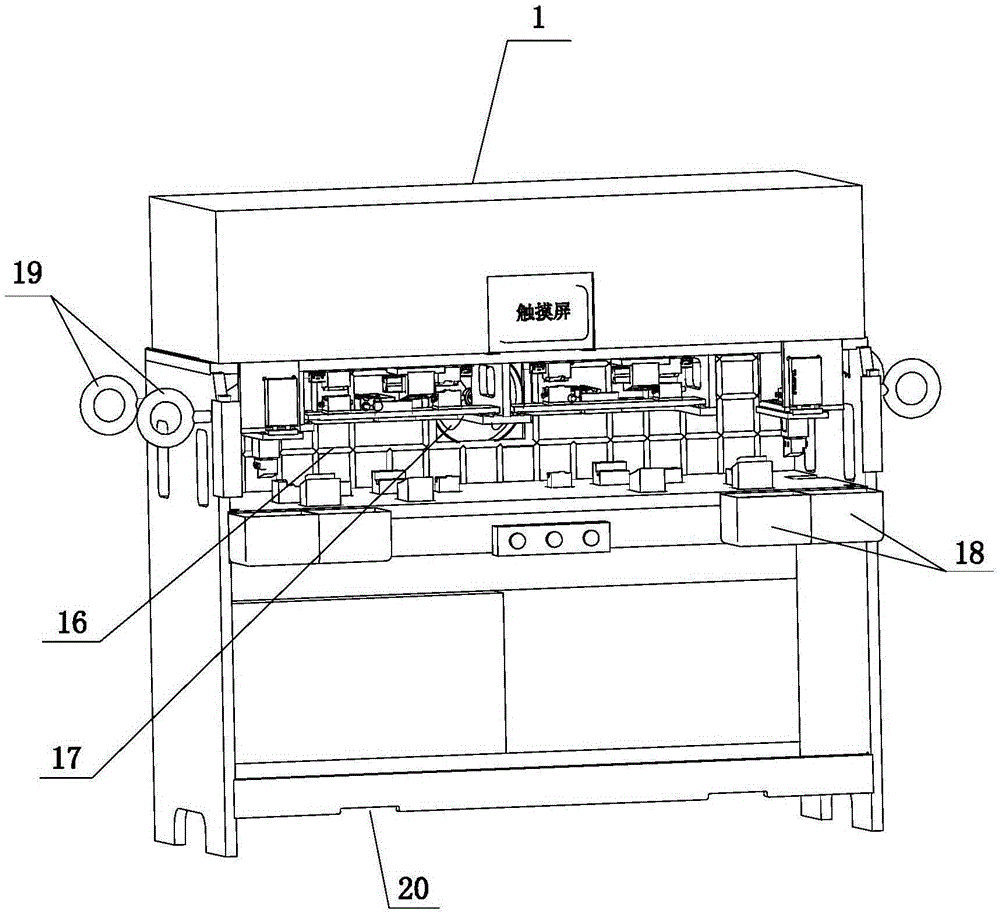

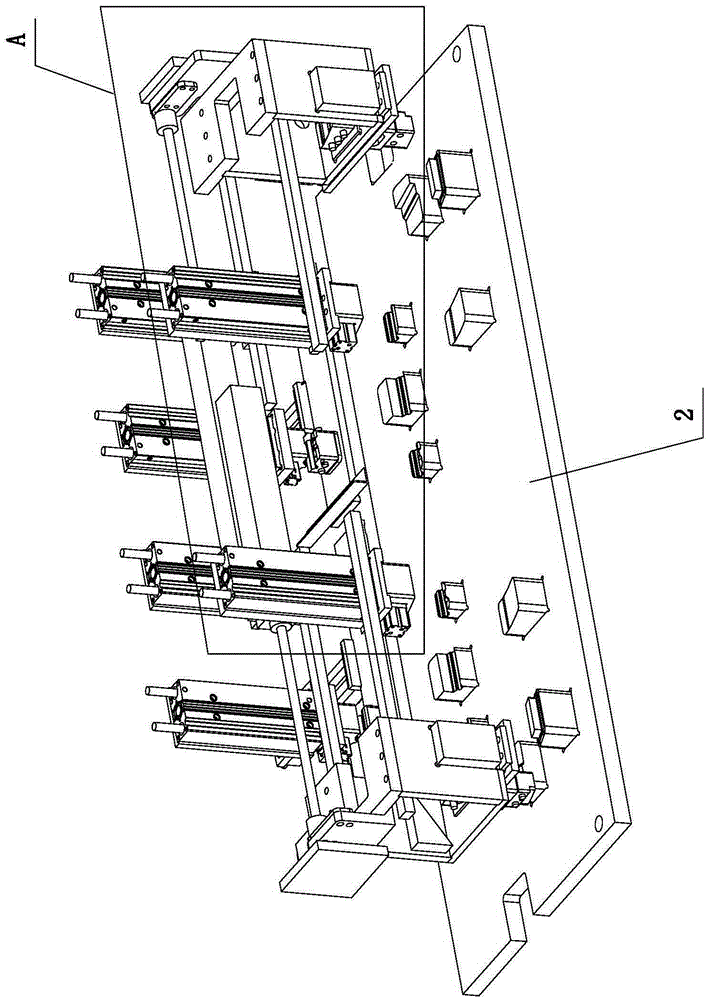

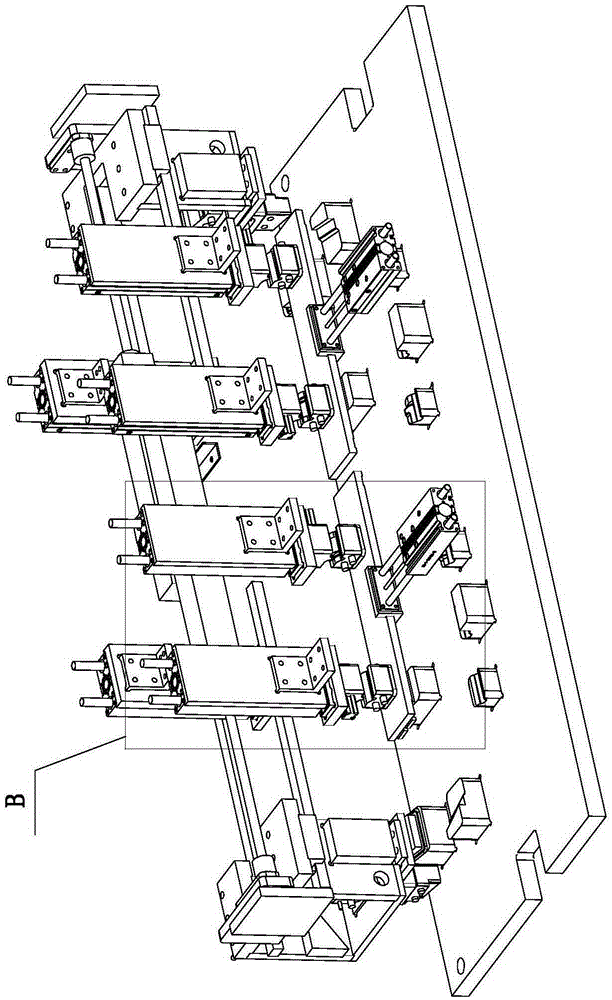

[0026] see Figure 1 to Figure 6 As shown, the plastic buckle welding tool for the front trim panel of the automobile luggage compartment partition of the present invention includes a frame 1, and the frame 1 is provided with a working chamber. The working chamber is provided with a welding assembly and a working table 2 for placing a front decorative panel. The welding assembly includes at least one welding unit. The welding unit includes a clamp for clamping the PP plastic part, a main ironing head 3, a first pushing device 6 for pushing the clamp to the joint between the front trim panel 4 and the PP plastic part 5, and the main ironing head 3 Push to the second pushing device 7 below the clamp. The clamp is connected to the movable end of the first pushing device 6 . The main iron 3 is connected to the movable end of the second pushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com