Layered packaging device and layered packaging method

A technology of moving parts and transmission mechanisms, applied in the field of layered packaging devices for fiber products, can solve the problems of roll-type toilet paper dumping, unfavorable procurement and use, limited packaging capacity, etc., and achieves large packaging capacity, convenient procurement and use, The effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

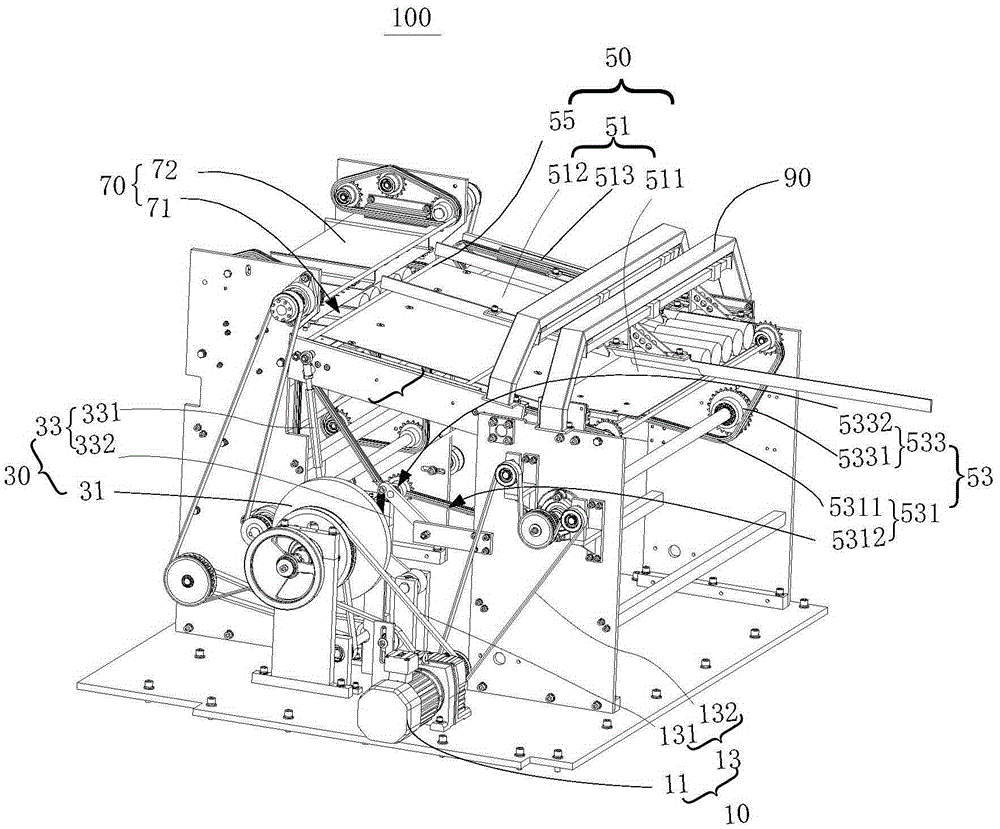

[0032] see figure 1 , the present invention provides a layered packaging device 100 for layered packaging a plurality of products to be packaged, the products to be packaged may be but not limited to roll fiber products. The packaging device 100 includes: a transmission mechanism 10 , a linkage mechanism 30 , a transmission mechanism 50 , a swing mechanism 70 and a height limiting mechanism 90 .

[0033] The transmission mechanism 10 is connected to the linkage mechanism 30 and the transmission mechanism 50 to provide power to the linkage mechanism 30 and the transmission mechanism 50 .

[0034] It can be understood that the transmission mechanism 10 can also be connected with the swing mechanism 70 to provide power for the swing mechanism 70 to deliver the product to be packaged to the packaging bag or box.

[0035] The transmission mechanism 10 includes a power member 11 and a transmission member 13, the power member 11 is used to provide power, one end of the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com